Preparation method of special-shaped negative curvature composite ceramic wave-transparent radome based on winding forming

A technology of composite ceramics and winding molding, which is applied to ceramic molding machines, manufacturing tools, etc., can solve the problems that fabrics cannot be woven with negative curvature, long process cycle, and prone to wrinkles, so as to avoid extremely easy wrinkles and improve densification The effect of speed and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method for a special-shaped negative-curvature composite ceramic radome cover body of a certain type of weapon system, the cross-sectional major axis of the special-shaped negative-curvature composite ceramic radome cover body is 400mm, the short axis is 400mm, and the length is 1200mm, including the following steps:

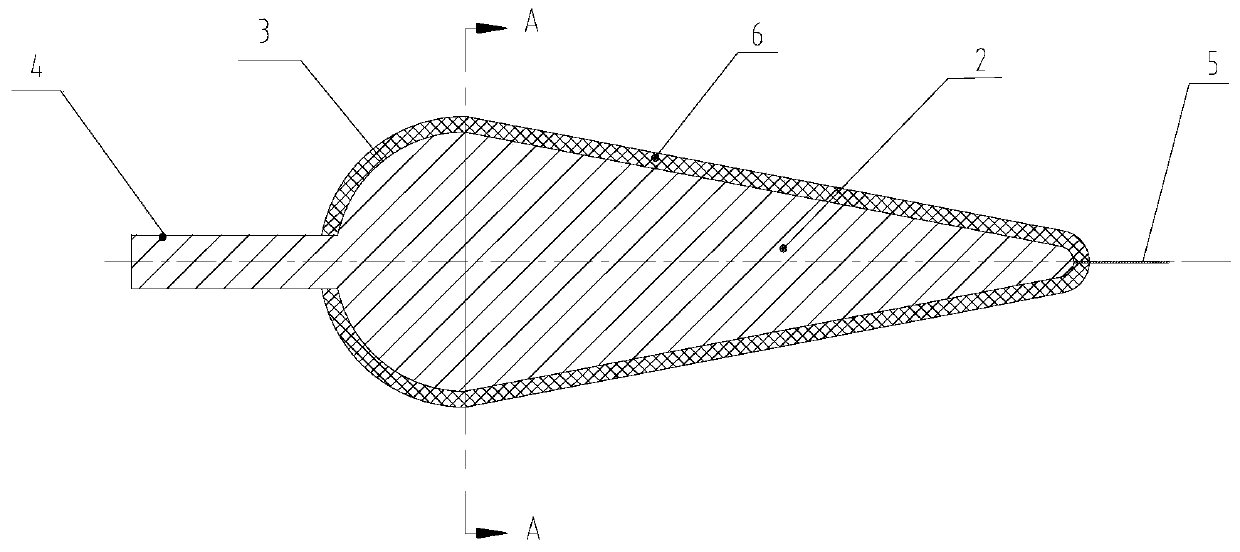

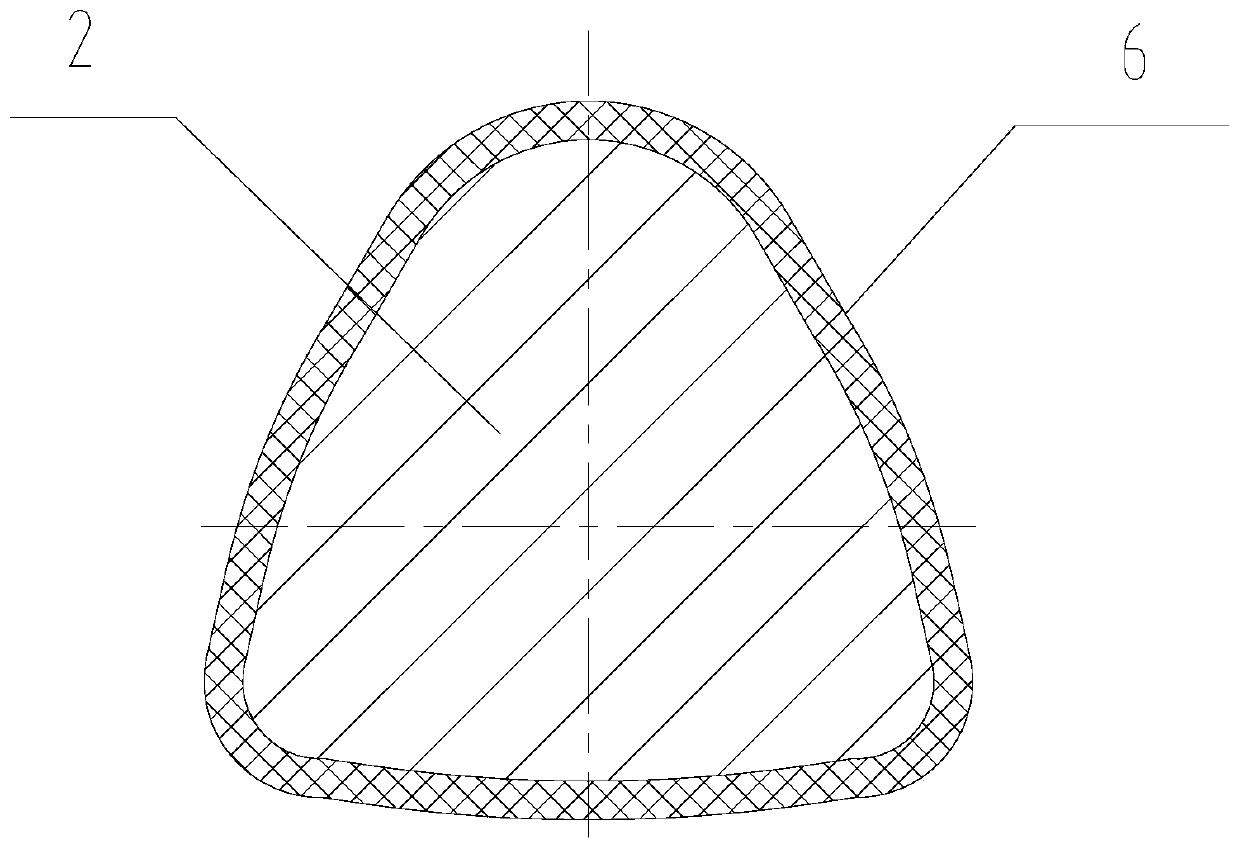

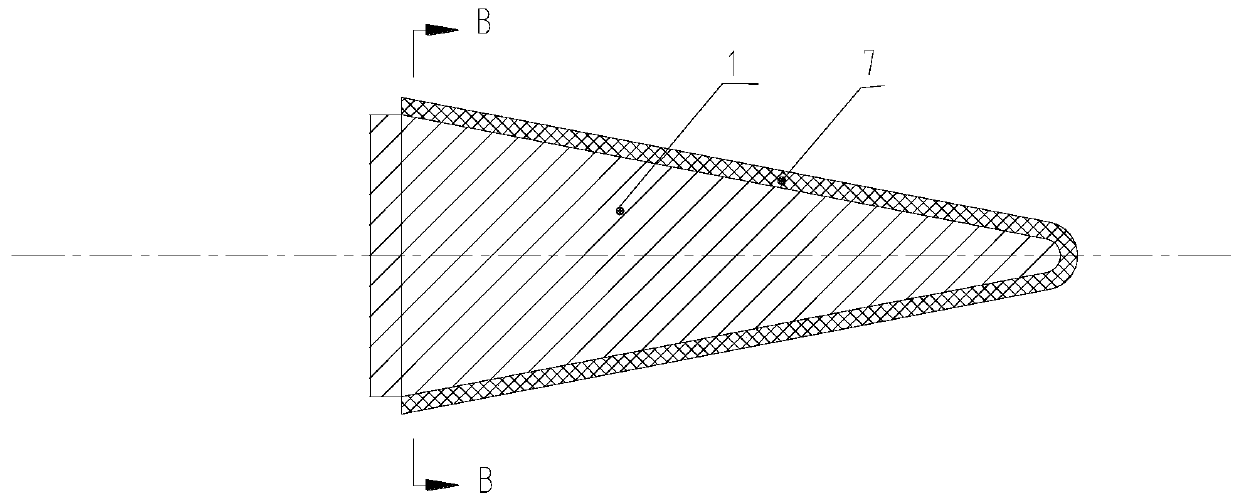

[0043] 1) Mandrel preparation: design and prepare the shaped mandrel and the winding mandrel according to the structure and size of the radome body, as shown in the figure, the shaped mandrel 1 has a negative curvature concave surface, and the winding mandrel 2 has a positive curvature convex shape In terms of surface, the negative curvature concave surface of the shaping mandrel 1 and the positive curvature convex surface of the winding mandrel 2 are mirror images; the shaping mandrel 1 and the winding mandrel 2 both have an open end and a closed end, and the opening size is determined by the opening end It gradually decreases toward the clo...

Embodiment 2

[0052] A preparation method for a special-shaped negative-curvature composite ceramic radome cover body of a certain type of weapon system, the long axis of the section of the special-shaped negative-curvature composite ceramic radome cover body is 300mm, the short axis is 150mm, and the length is 600mm, including the following steps:

[0053] 1) Mandrel preparation: design and prepare the shaped mandrel and the winding mandrel according to the structure and size of the radome body, as shown in the figure, the shaped mandrel 1 has a negative curvature concave surface, and the winding mandrel 2 has a positive curvature convex shape In terms of surface, the negative curvature concave surface of the shaping mandrel 1 and the positive curvature convex surface of the winding mandrel 2 are mirror images; the shaping mandrel 1 and the winding mandrel 2 both have an open end and a closed end, and the opening size is determined by the opening end It gradually decreases toward the closed...

Embodiment 3

[0062] A preparation method for a special-shaped negative-curvature composite ceramic radome cover body of a certain type of weapon system, the cross-sectional major axis of the special-shaped negative-curvature composite ceramic radome cover body is 500mm, the short axis is 300mm, and the length is 1600mm, including the following steps:

[0063] 1) Mandrel preparation: design and prepare the shaped mandrel and the winding mandrel according to the structure and size of the radome body, as shown in the figure, the shaped mandrel 1 has a negative curvature concave surface, and the winding mandrel 2 has a positive curvature convex shape In terms of surface, the negative curvature concave surface of the shaping mandrel 1 and the positive curvature convex surface of the winding mandrel 2 are mirror images; the shaping mandrel 1 and the winding mandrel 2 both have an open end and a closed end, and the opening size is determined by the opening end It gradually decreases toward the clo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com