A kind of preparation method of carbon nanotube/cellulose lightweight wave-absorbing foam

A technology of carbon nanotubes and multi-walled carbon nanotubes, which is applied in chemical instruments and methods, ceramic products, and other chemical processes, and can solve the problems of high density, complex preparation process of wave-absorbing foam, and difficult control of electromagnetic wave absorption/shielding performance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

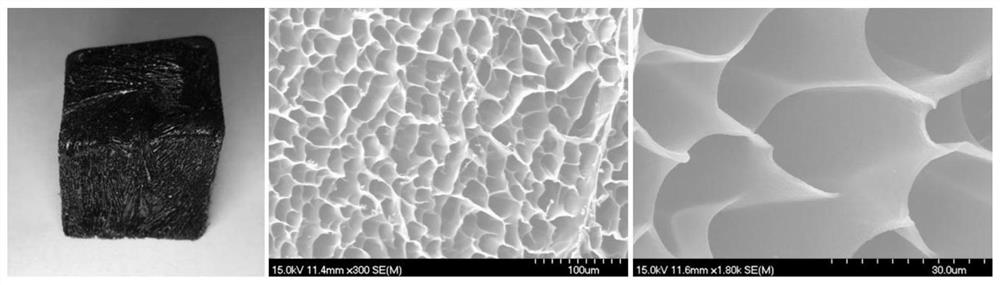

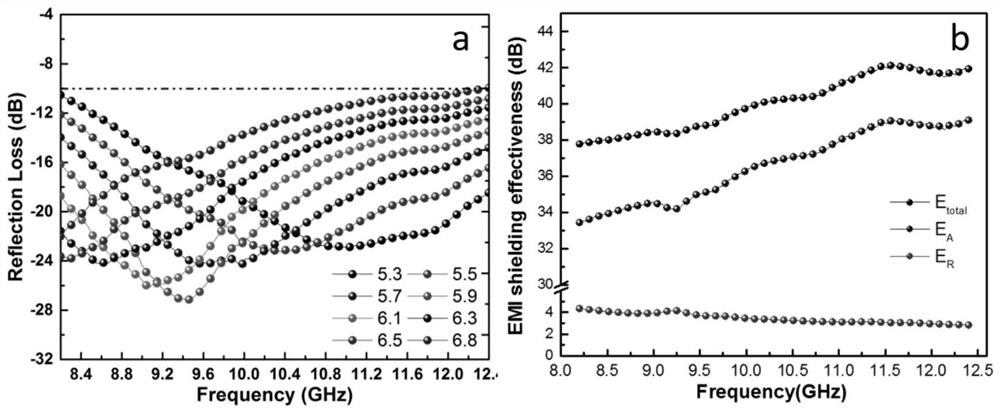

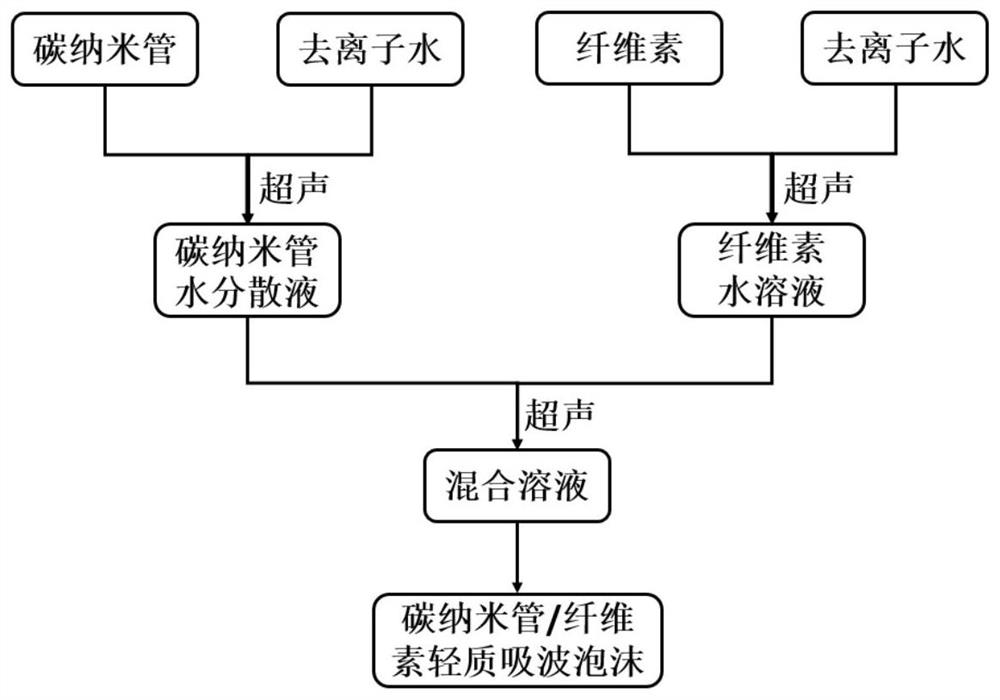

[0024] Put 3g of multi-walled carbon nanotubes in 97ml of deionized water, and ultrasonically disperse for 3 hours to obtain a uniformly dispersed aqueous dispersion of multi-walled carbon nanotubes; place 1g of nanocellulose fibers in 99ml of deionized water, and ultrasonically disperse for 1h to obtain nanofibers cellulose aqueous solution; put 10ml multi-walled carbon nanotube aqueous dispersion in 70ml nanocellulose fiber aqueous solution, and ultrasonicate for 1.5h to obtain a mixed solution; put the mixed solution in a cube-shaped mold, and cool down to -60°C at 5°C / min Pre-freeze for 6 hours at ℃, and dry for 30 hours under 0.1Pa vacuum condition. The carbon nanotube / cellulose light wave-absorbing foam can be obtained after demoulding. When the thickness of the prepared foam varies within the range of 5.3-6.8mm, it has excellent absorbing properties in the X-band range that can effectively absorb and cover all frequency bands (EAB=4.2GHz, and can absorb more than 99% of...

Embodiment 2

[0026] Put 1.5g of single-walled carbon nanotubes in 98.5ml of deionized water, and ultrasonically disperse for 5 hours to obtain a uniformly dispersed single-walled carbon nanotube aqueous dispersion; place 0.5g of carboxymethyl cellulose in 99.5ml of deionized water, and ultrasonically disperse 1h to obtain an aqueous solution of carboxymethyl cellulose; put 50ml of single-walled carbon nanotube aqueous dispersion in 20ml of aqueous carboxymethylcellulose, and ultrasonicate for 2h to obtain a mixed solution; place the mixed solution in a cuboid mold and heat / min to -60°C for pre-freezing for 8 hours, and dried for 40 hours under 0.1Pa vacuum condition. The carbon nanotube / cellulose light wave-absorbing foam can be obtained after demoulding. The prepared foam has an electromagnetic wave shielding performance greater than 37dB in the X-band. Its electromagnetic shielding performance is as figure 2 as shown in b.

Embodiment 3

[0028] Put 2g of aminated carbon nanotubes in 98ml of deionized water, and ultrasonically disperse for 4h to obtain a uniformly dispersed aqueous dispersion of aminated carbon nanotubes; put 1.5g of carboxymethyl cellulose in 98.5ml of deionized water, and ultrasonically disperse for 2h, Obtain an aqueous solution of carboxymethyl cellulose; put 30ml of single-walled carbon nanotube aqueous dispersion in 50ml of aqueous carboxymethyl cellulose, and ultrasonicate for 2 hours to obtain a mixed solution; Lower the temperature to -60°C for pre-freezing for 6 hours, and dry for 36 hours under 0.1Pa vacuum condition. The carbon nanotube / cellulose light wave-absorbing foam can be obtained after demolding. The prepared foam has excellent absorbing performance at X.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com