Cyan mechanoluminescent material applied to low-temperature detection as well as preparation method and application thereof

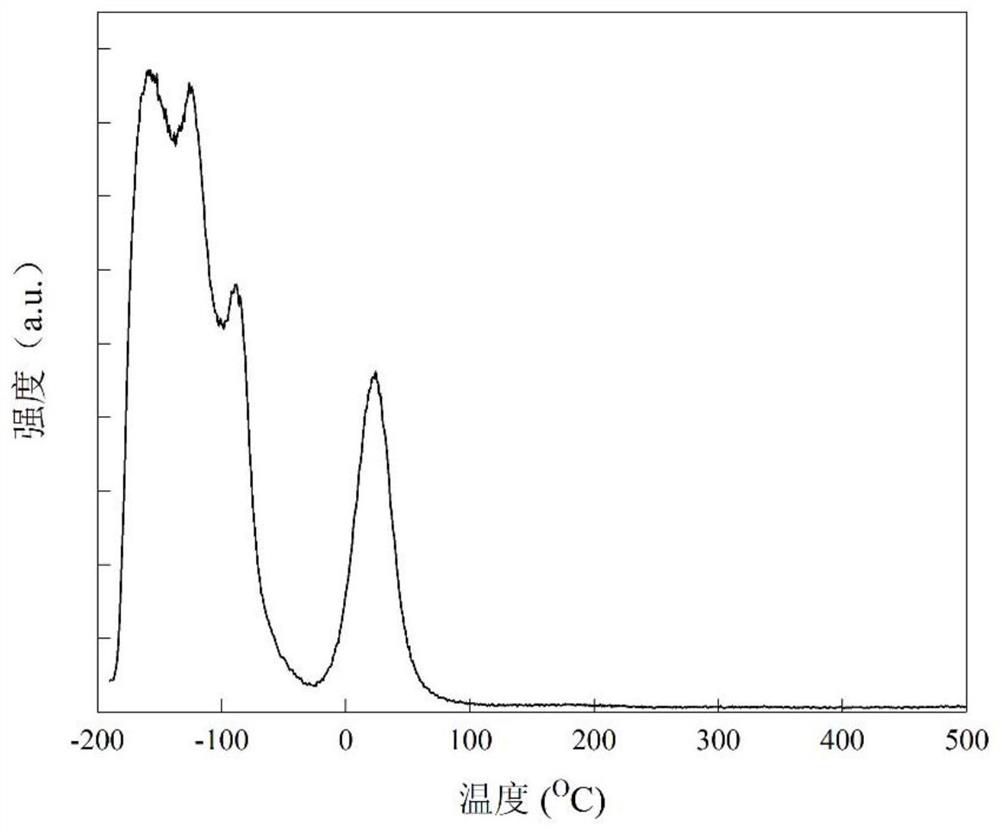

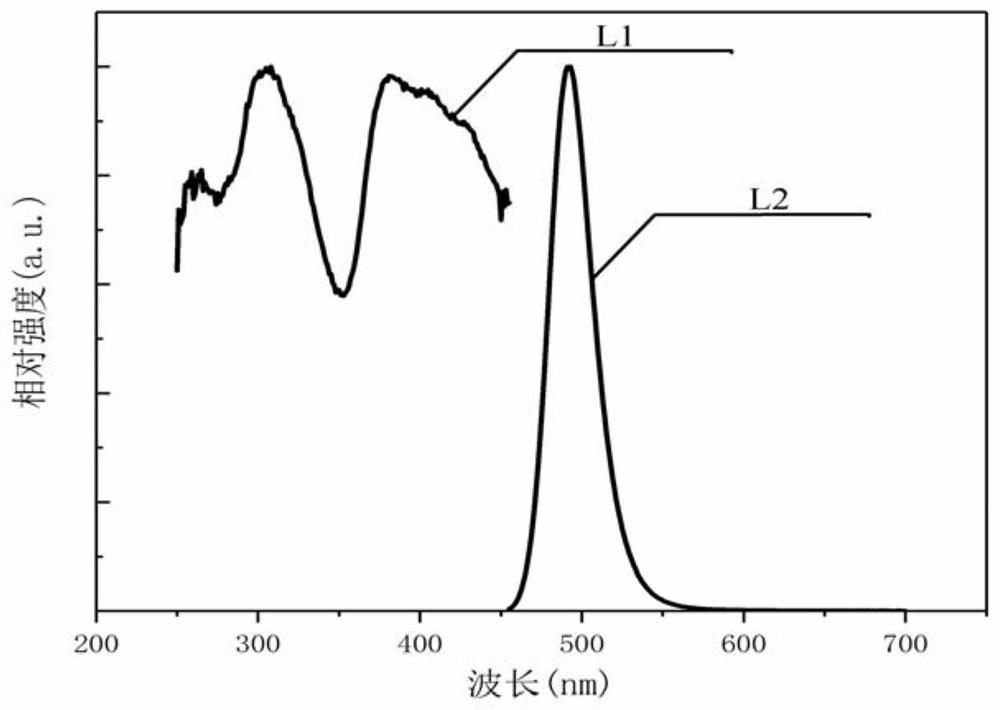

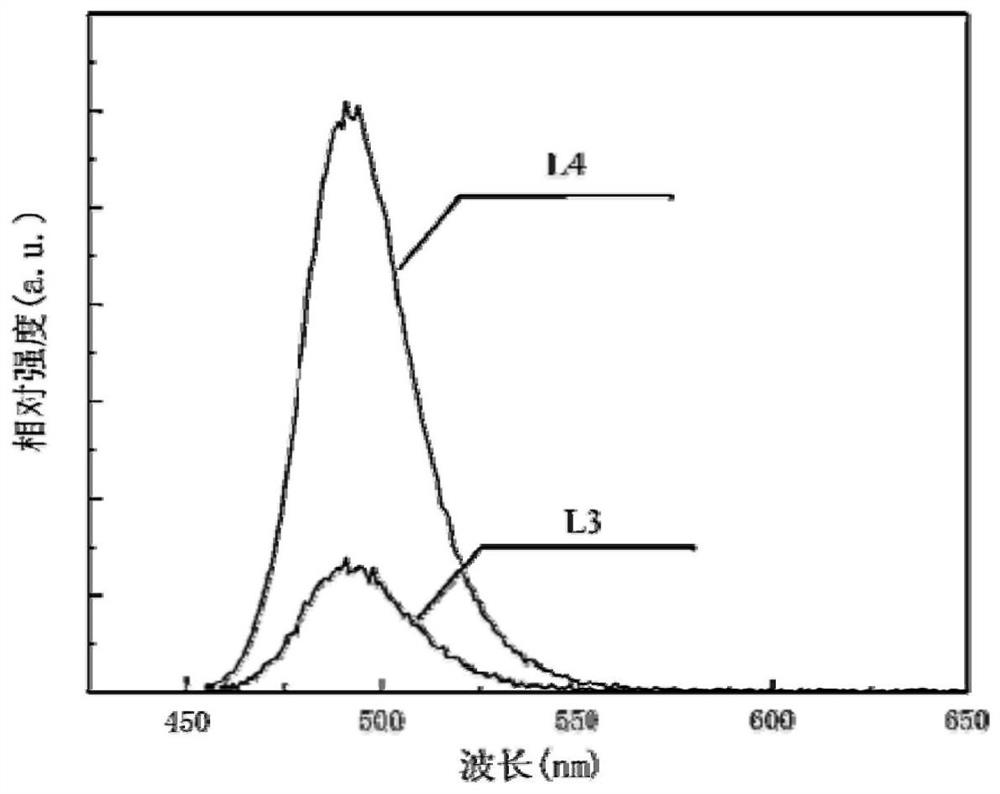

An electroluminescence and cyan technology, applied in the field of cyan electroluminescence materials and their preparation, can solve the problems of lack of low temperature trap energy level, decreased application sensitivity, loss of stress detection ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a method for preparing the above-mentioned cyan electroluminescent material, comprising the following steps:

[0042] (1) Weigh the raw material BaCO according to the stoichiometric ratio 3 , SiO 2 、Eu 2 o 3 , use a planetary ball mill according to the weight ratio of raw materials: balls: alcohol = 1:1:0.05 to perform ball milling for 24 hours to obtain a slurry mixture, place it in an oven and dry it at 60°C for 19 hours, then take it out and sieve it to obtain a uniformly dispersed powder;

[0043] (2) Put the powder in a crucible and put it in a tube furnace to feed a mixed gas with a volume ratio of 10% hydrogen and 90% nitrogen, and sinter at 1200°C for 6h to obtain Ba (2-2X) SiO 4 :Eu 2+ (2X) ;

[0044] (3) Take raw material Ba by stoichiometric ratio (2-2X) SiO 4 :Eu 2+ (2X) 、Si 3 N 4 ; Use a planetary ball mill according to the weight ratio of raw materials: balls: alcohol = 1:1:0.05 to perform ball milling for 1...

Embodiment 1

[0056] The preparation process of a kind of cyan electroluminescent material is as follows:

[0057] (1) Weigh the raw material BaCO according to the stoichiometric ratio 3 , SiO 2 、Eu 2 o 3 , use a planetary ball mill according to the weight ratio of raw materials: balls: alcohol = 1:1:0.05 ball mill the slurry mixture for 24 hours, put the obtained slurry mixture in an oven at 60 ° C for 19 hours, then take it out and sieve , to obtain a uniformly dispersed powder;

[0058] (2) Put the powder in a crucible, place it in a tube furnace, feed 10% hydrogen-nitrogen mixed gas, and sinter at 1200°C for 6 hours to obtain Ba 1.9998 SiO 4 :Eu 2+ 0.0002 ;

[0059] (3) Take raw material Ba by stoichiometric ratio 1.9998 SiO 4 :Eu 2+ 0.0002 、Si 3 N 4 ; Use a planetary ball mill according to the weight ratio of raw materials: balls: alcohol = 1:1:0.05 to perform ball milling for 1.5 hours to obtain a slurry mixture, place it in an oven and dry it at 60°C for 19 hours, then ...

Embodiment 2

[0063] The preparation process of a kind of cyan electroluminescent material is as follows:

[0064] (1) Weigh the raw material BaCO according to the stoichiometric ratio 3 , SiO 2 、Eu 2 o 3 , use a planetary ball mill according to the weight ratio of raw materials: balls: alcohol = 1:1:0.05 ball mill the slurry mixture for 24 hours, put the obtained slurry mixture in an oven at 60 ° C for 19 hours, then take it out and sieve , to obtain a uniformly dispersed powder;

[0065](2) Put the powder in a crucible, place it in a tube furnace, feed 10% hydrogen-nitrogen mixed gas, and sinter at 1200°C for 6 hours to obtain Ba 1.0 SiO 4 :Eu 2+ 1.0 ;

[0066] (3) Take raw material Ba by stoichiometric ratio 1.0 SiO 4 :Eu 2+ 1.0 、Si 3 N 4 ; Use a planetary ball mill according to the weight ratio of raw materials: balls: alcohol = 1:1:0.05 to perform ball milling for 1.5 hours to obtain a slurry mixture, place it in an oven and dry it at 60°C for 19 hours, then take it out a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com