Composite material power battery pack having damage perception effect and preparation method thereof

A power battery pack, power battery technology, applied in battery pack components, circuits, electrical components, etc., can solve the problems of strength and stiffness reduction, damage perception, not integrated forming, etc., to achieve the effect of weight reduction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

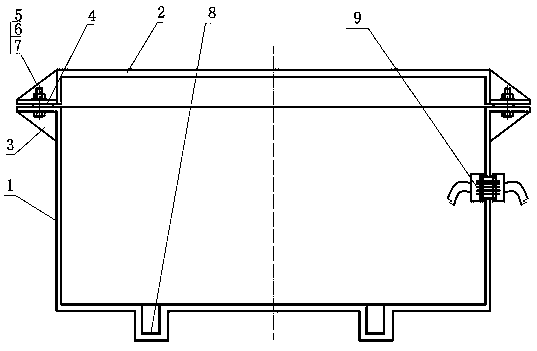

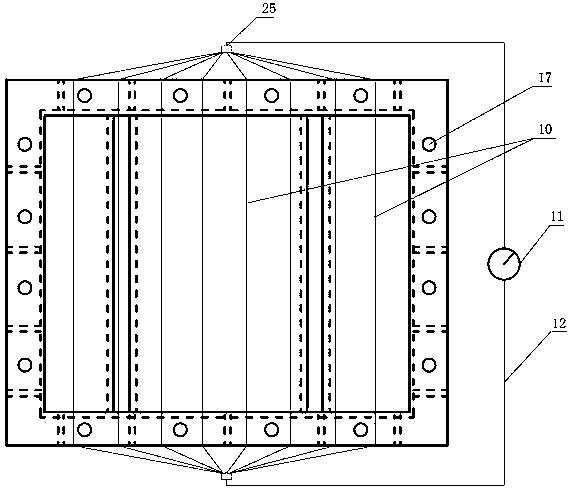

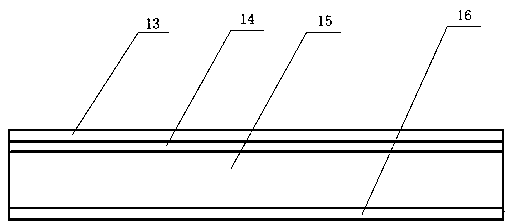

[0029] Such as figure 1 and figure 2 As shown, the present invention includes a power battery base 1, an upper cover 2, a sealing gasket 4 and a cable lead-out device 9; 4. Press and seal through the connecting piece bolts 5, nuts 6 and gaskets 7; there are reinforcing ribs 3 between the bolt pressing surface of the upper cover 2 connecting the periphery of the flange and the protrusion of the upper cover, and there are a plurality of flanges Bolt holes 17; the corners around the inside of the power battery base 1 and the U-shaped groove 8 in the middle of the bottom of the power battery base 1 have rounded transitions; the middle of the bottom of the power battery base 1 is provided with two U-shaped grooves with a reinforced bottom 8; The bottom surface of the power battery base 1 and the upper cover 2 and the middle of the surrounding composite la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com