Intelligent guiding rule for plane range measurement

An extremely poor and intelligent technology, applied in the field of measurement, can solve the problems of not being able to obtain the extreme difference, and achieve the effect of convenient and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

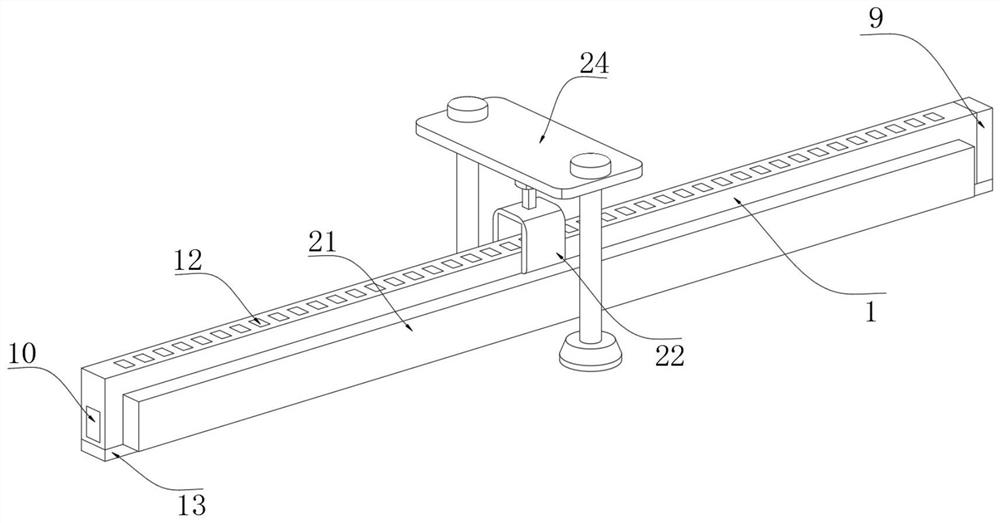

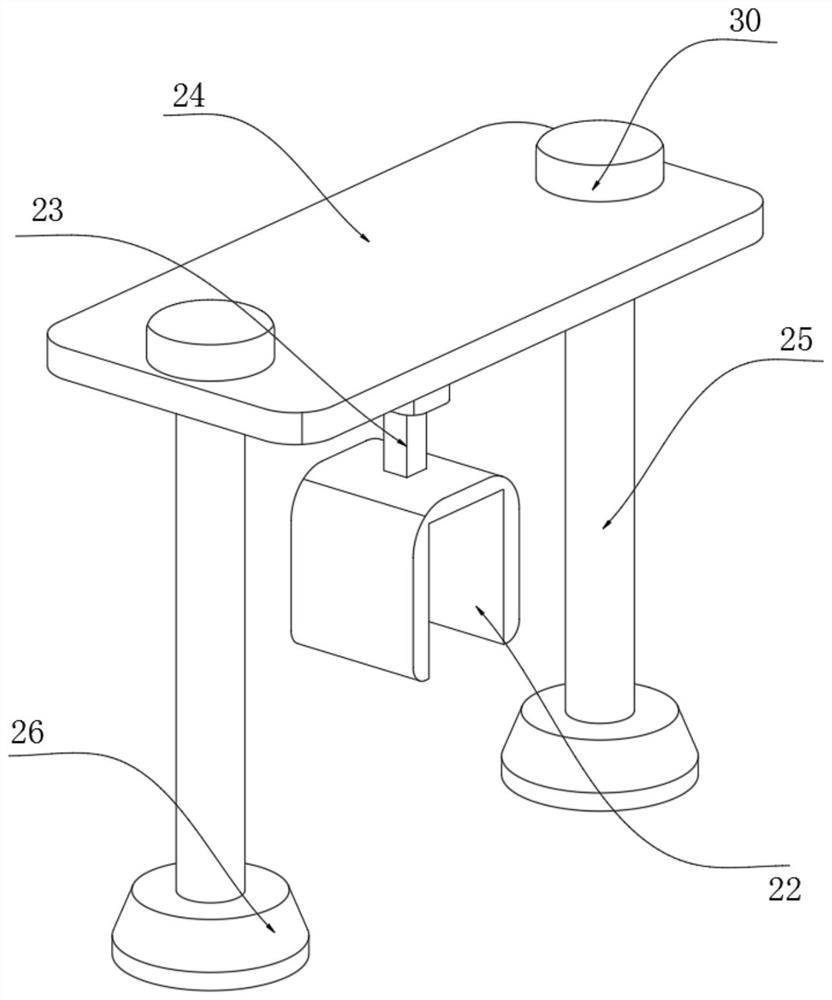

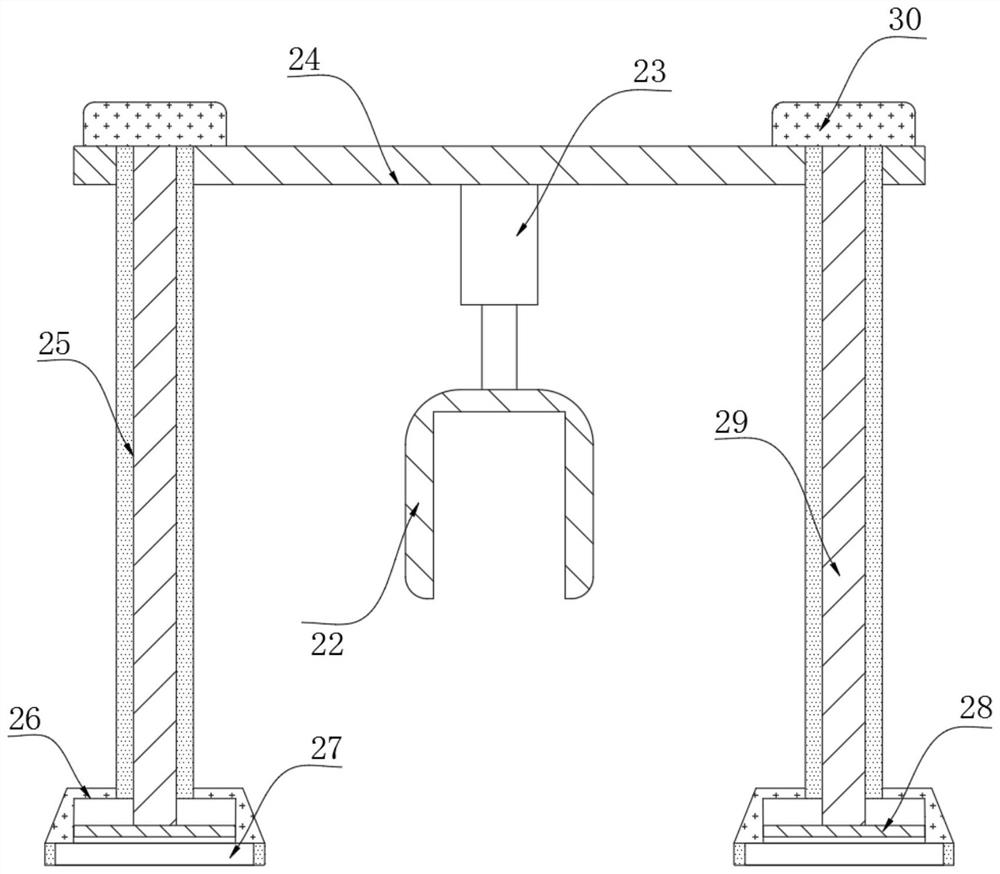

[0026] refer to Figure 1-5 , an intelligent ruler for plane range measurement, comprising a ruler body 1, a trigger chamber 2 is opened on the upper part of the ruler body 1, and a plurality of distribution plates 4 are connected to the inner wall of the trigger chamber 2 through a plurality of return springs 3, each The bottoms of each distribution plate 4 are fixed with connecting rods 5, and the bottom of each connecting rod 5 runs through the side wall of the trigger cavity 2 and is fixed with a cutout plate 6, and the bottom of each cutout plate 6 is fixed with a contact rod 7, each The upper ends of each light-cutting plate 6 are equipped with a positioning mechanism, the outer wall of the ruler body 1 is provided with a graphic display mechanism, the outer wall of the ruler body 1 is connected with a co-measurement mechanism, and the bottom of the ruler body 1 is fixed with a protective bottom plate 13, which is used for Avoid damage to the contact rod 7 and ensure mea...

Embodiment 2

[0037] refer to figure 1 and Figure 4 The difference between the present embodiment and the first embodiment lies in the difference of the graphic display mechanism. In the present embodiment, the graphic display mechanism includes side loading grooves 19 opened on both sides of the ruler body 1, and the inner walls of the two side loading grooves 19 are respectively fixed with The side display panel 20 and the side light box 21, the side wall of the side display panel 20 is coated with a photochromic substance, and the side wall of the side display panel 20 is provided with a scale;

[0038] When measuring, the light emitted by the side light box 21 will be able to completely cover each light-cutting plate 6, and there will be no common blocking position between each light-cutting plate 6 due to overlap, and the light that can be blocked by each light-cutting plate 6 is relatively independent , so the colored lines displayed on the side display panel 20 will be independent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com