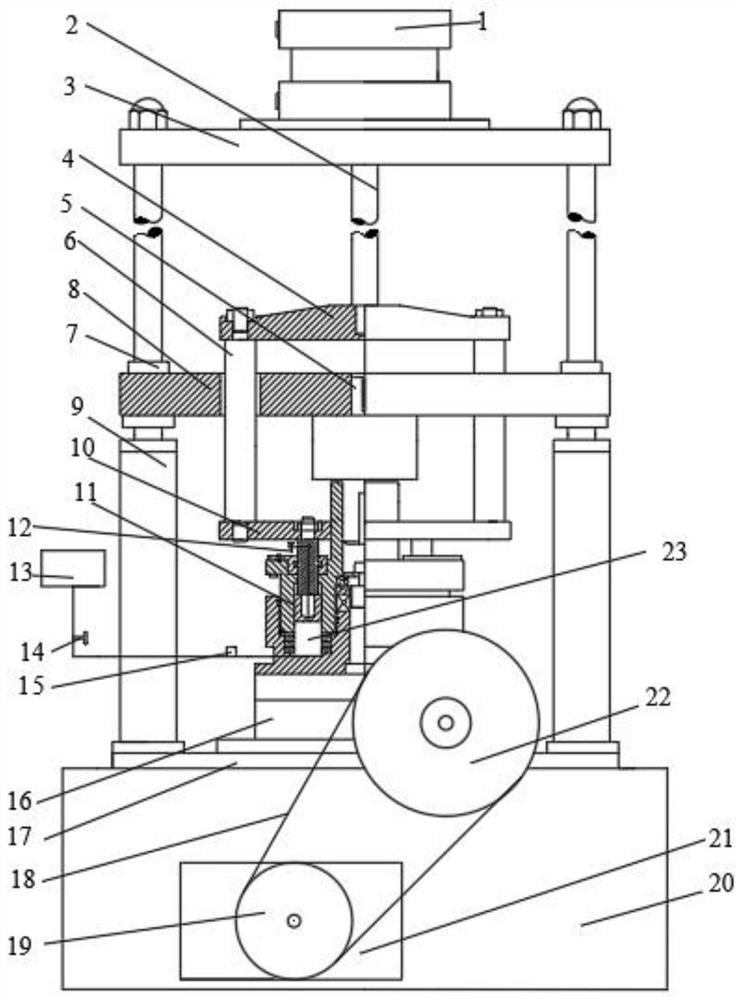

Rotary ball stacked ring type shear box and ring shear apparatus with same

A ball-stacked ring-type and shear box technology, which is applied in the field of ring shear instruments, can solve problems affecting test accuracy and achieve the effects of improving test accuracy, overcoming lateral friction, and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

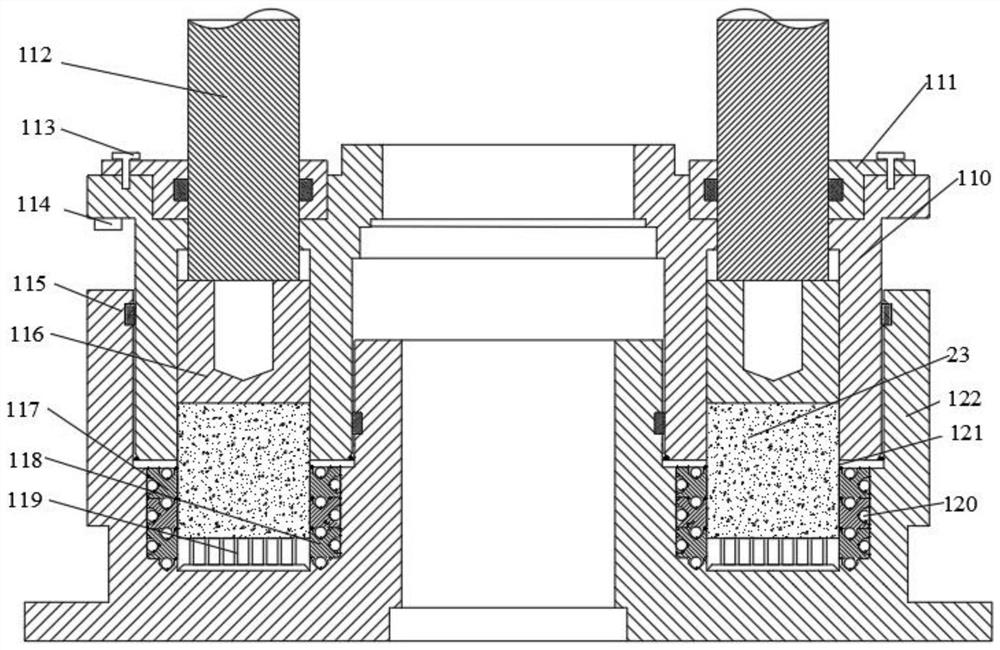

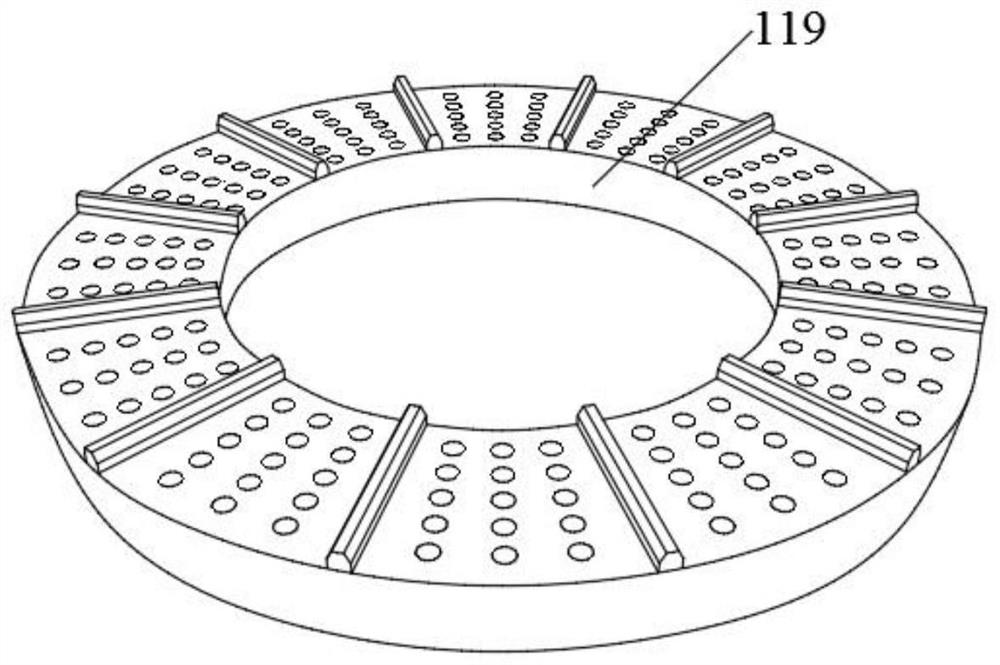

[0036] like Figure 2-Figure 7 As shown, the embodiment of the present invention provides a rotary ball stacked ring shear box and a ring shear instrument with the shear box, including: figure 2 , 5 As shown in , 6, the upper box includes: a cylinder I110, the middle part of which is provided with an installation hole I, the bottom of which is provided with a ring part I around the installation hole I, and an annular groove I is provided around the center of the ring part I, and the ring groove I The inner bottom of the I is evenly distributed with a plurality of guide holes for piercing the pressure column 112; the pressure ring 116 is arranged in the annular groove 1, and its top is connected to the lower end of the pressure column 112; figure 2 , 4 7. The lower box shown in 7, which includes: a cylinder II122, the middle of which is provided with an installation hole II, the top of which is provided with a ring II around the installation hole II, and an annular groove I...

Embodiment 2

[0038] On the basis of Embodiment 1, in order to overcome the problem that the ring body and the ball 120 of the stacked ring fall during the disassembly and assembly of the annular sample 23, the device also includes two annular backing plates 121, two backing plates 121 Correspondingly arranged on the top of the inner moving ring 118 and the outer moving ring 117, and the backing plate 121 and the inner wall of the annular groove II are fixed.

[0039] Wherein, the width of the backing plate 121 is greater than that of the ring body.

Embodiment 3

[0041] On the basis of Example 1, in order to further reduce the friction between the ring sample 23 and the inner wall of the ring groove II of the lower box, the space between the ball 120 and the ring body is filled with butter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com