A cloud-edge collaborative factory digital twin monitoring modeling system and modeling method

A modeling module and twinning technology, applied in the direction of comprehensive factory control, comprehensive factory control, general control system, etc., can solve the problems of heavy integration workload between systems, low data interaction efficiency, and inability to faithfully reflect the real-time operating status of the physical world

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

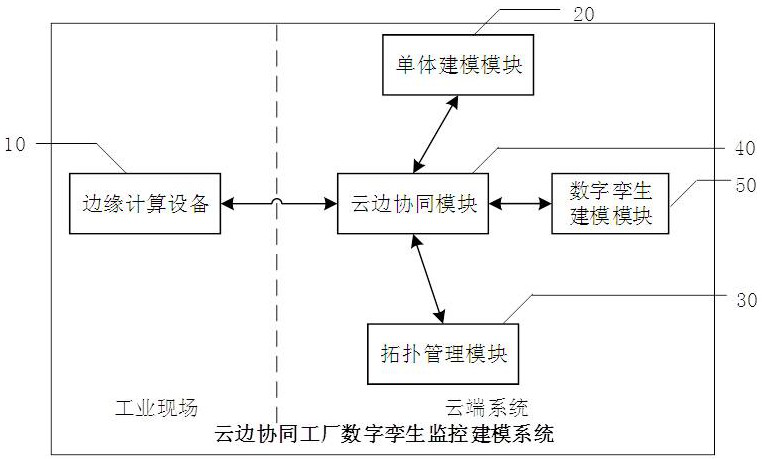

[0053] figure 1 It is a schematic structural diagram of a cloud-edge collaborative factory digital twin monitoring and modeling system according to an embodiment of the present invention. This embodiment is applicable to the situation where the digital twin is monitored by a server or other equipment. The system can be implemented in the form of software and / or hardware, and can be integrated in electronic equipment, such as integrated server equipment.

[0054] The modeling system includes a cloud system and an edge computing device 10 set on an industrial site. The cloud system is composed of a single modeling module 20, a topology management module 30, a cloud-edge collaboration module 40 and a digital twin modeling module 50, and the edge computing device 10 is connected to the cloud-edge collaboration module 40 of the cloud system.

[0055] In this embodiment, the edge computing device 10 refers to a device or hardware with certain computing and storage capabilities depl...

Embodiment 2

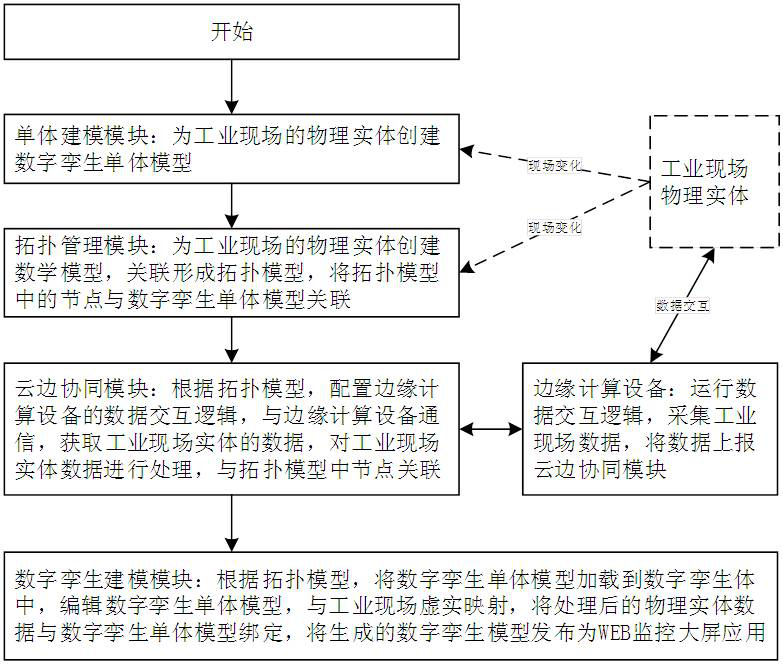

[0075] combine figure 2 , the embodiment of the present invention proposes a cloud-edge collaborative factory digital twin monitoring modeling method, and the modeling method in the second embodiment of the present invention can be realized by the modeling system in the first embodiment of the present invention.

[0076] This modeling method includes the following steps:

[0077] Step 1. Create a digital twin monomer model through the monomer modeling module 20 according to the actual three-dimensional size, associated data, and spatial actions of each physical entity on the industrial site, and maintain the relationship between the digital twin monomer model and the physical entity. The interface for interactive data enables the single model to run spatial actions driven by data and map with physical entities.

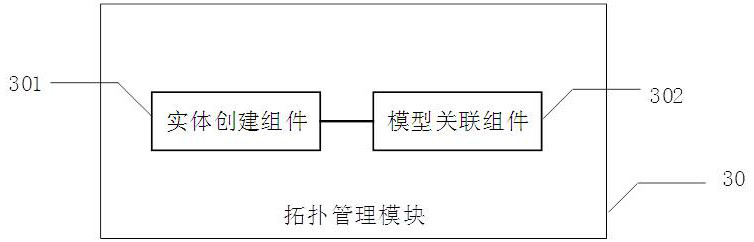

[0078] Step 2, on the entity creation component 301 page of the topology management module 30, according to the type, quantity, connection relationship of the physi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com