Copper-aluminum mixed welding method and apparatus for chip welding

A chip welding and copper-aluminum technology, which is applied in the field of copper-aluminum hybrid welding methods and equipment for chip welding, can solve the problems of low reliability, short chip service life, and copper wires are easy to fall off, so as to improve the welding reliability and prolong the The effect of long service life, good welding reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

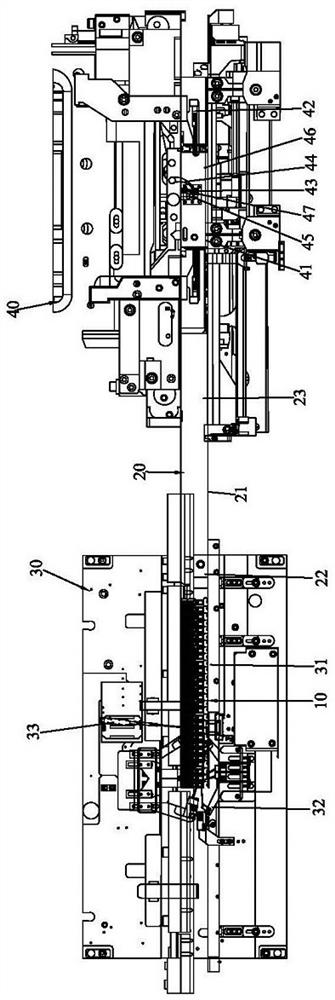

[0028] Please refer to figure 1 As shown, it shows the specific structure of the preferred embodiment of the present invention, including a conveying mechanism 20 for transporting the chip 10, an aluminum welding device 30 for welding an aluminum solder ball on the chip 10 and a A copper soldering device 40 for soldering a copper wire on a solder ball.

[0029] The conveying mechanism 20 includes a driving mechanism (not shown in the figure) and a conveyor belt 21 , the driving mechanism drives the conveyor belt 21 to run, and the two ends of the conveyor belt 21 extend into the aluminum welding device 30 and the copper welding device 40 respectively.

[0030] The aluminum welding device 30 is connected to the input end 22 of the conveying mechanism 20; in this embodiment, the aluminum welding device 30 has a first welding zone 31, the input end 22 of the conveying mechanism 20 extends into the first welding zone 31, the The side of the first bonding area 31 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com