Photocurable resin composition, photocurable resin article, and methods of fabricating the article

A technology of photocurable resin and resin, applied in the fields of photocurable resin, 3D printed resin products, and manufactured products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

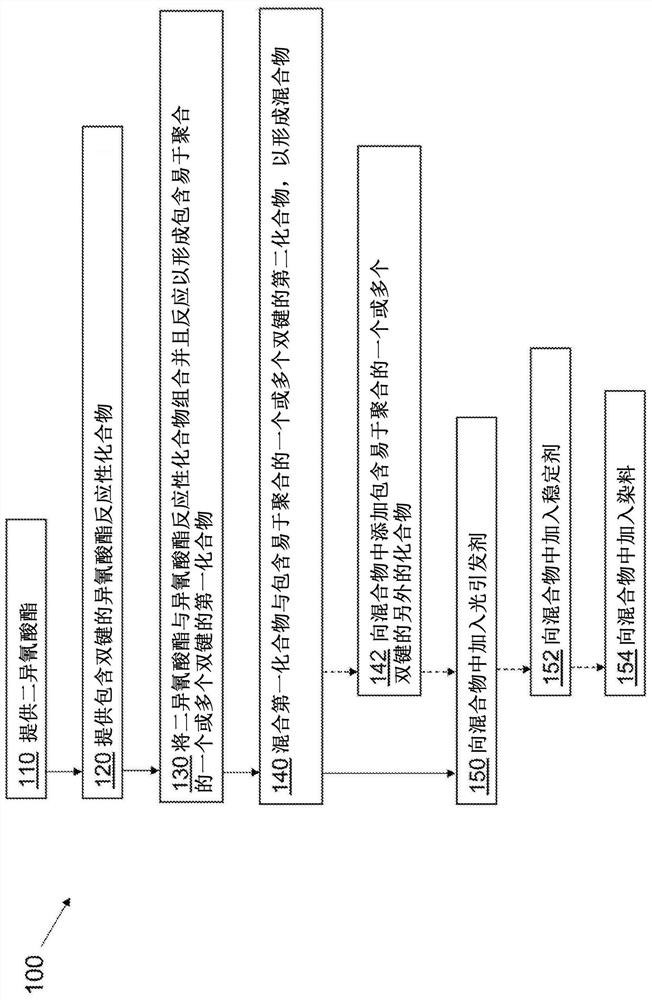

Method used

Image

Examples

experiment example

[0103]The invention will now be described with reference to the following examples. These examples are provided for the purpose of illustration only, and the invention is not limited to these examples, but encompasses all variations apparent as a result of the teaching provided herein.

[0104] Materials and methods

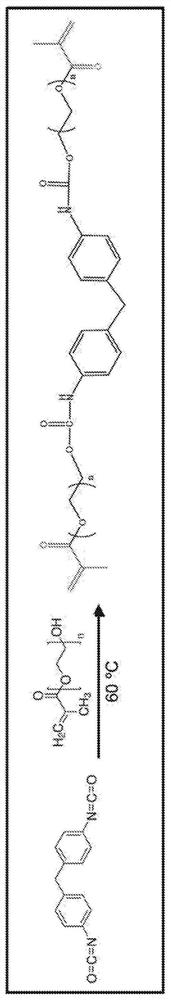

[0105] Synthesis of Photocurable MDI-PEGMA

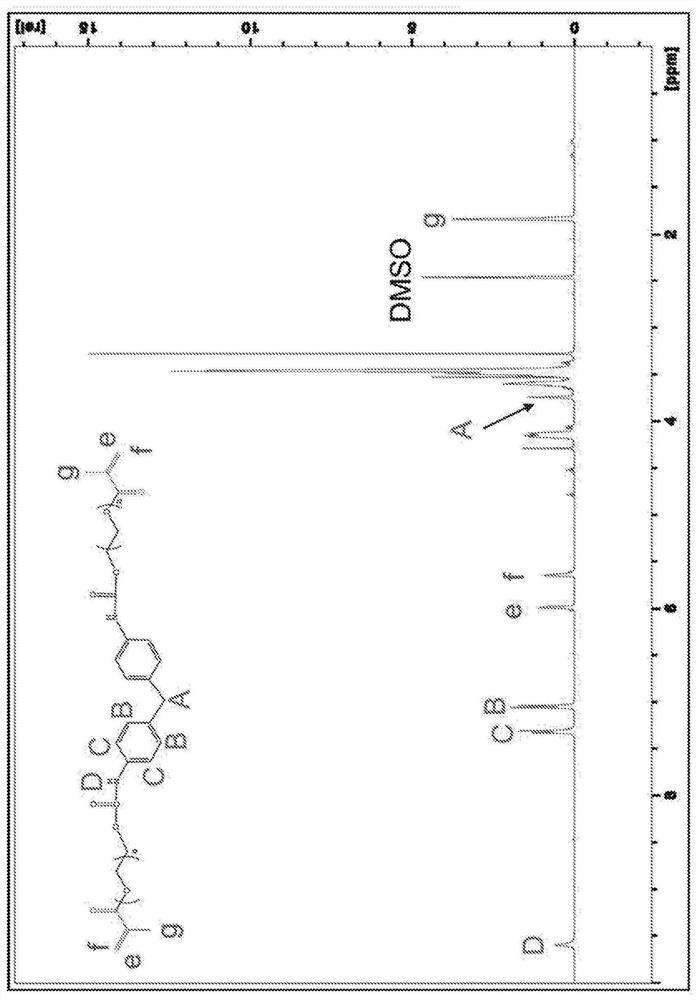

[0106] MDI-PEGMA was synthesized using 4,4'-methylene bis(phenylisocyanate) (MDI) (10.00 g, 40.00 mmol), which was added to a round bottom flask with inert atmosphere, stir bar and heated to 60°C. After the MDI reagent melted, poly(ethylene glycol) methacrylate (PEGMA) (32.55 mL, 100.00 mmol) was added dropwise, and reacted at 60° C. for 8 h. Afterwards, the reaction was allowed to proceed overnight at room temperature. The synthesized compound (MDI-PEGMA) was collected using a positive displacement pipette and analyzed by proton NMR spectroscopy ( 1 H NMR) and by Fourier transform infrared spectroscopy (FT-IR...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com