Disc type cloth film evaporator

An evaporator and disk-type technology, applied in the field of evaporation equipment, can solve problems such as inability to separate solids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

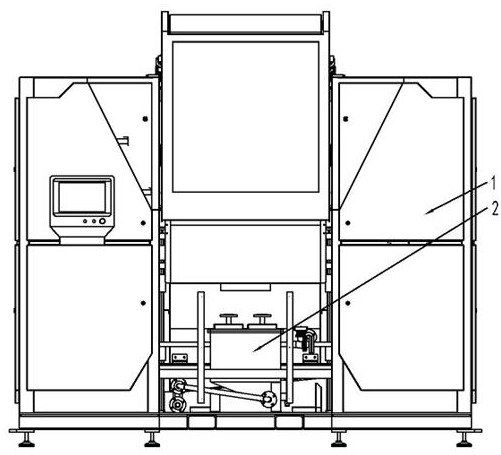

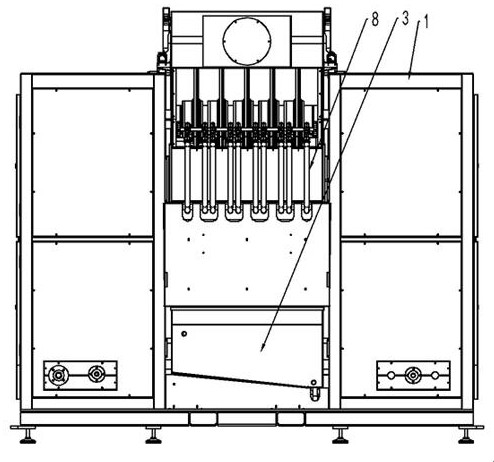

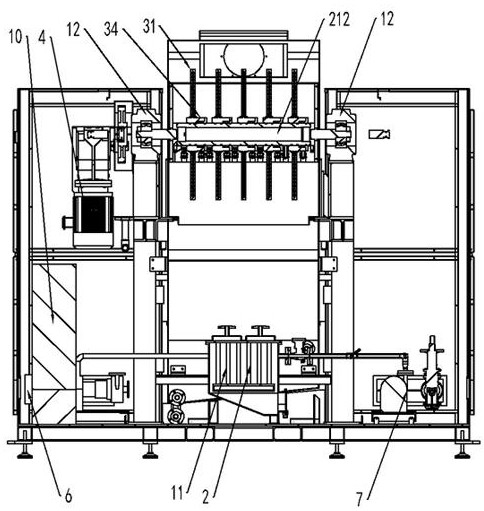

[0040] Examples such as Figure 1-19 As shown, a disc type cloth film evaporator includes a frame 1 for supporting the whole equipment, a rotatable disc evaporation device is arranged on the frame 1, a rotating device is arranged on the disc evaporating device, and the rotating device Driven by a driving device to rotate, the disc evaporator is connected with a waste heat recovery device and a scraping device, and the frame 1 is provided with a solid collection device.

[0041] The rotating device includes a shaft body 212 with a circular longitudinal section. One end of the shaft body 212 is coaxially fitted with the short end shaft 21 , and the other end is coaxially fitted with the long end shaft 22 .

[0042] One ends of the short-end shaft 21 and the long-end shaft 22 are respectively inserted into the corresponding ends of the shaft body 212 for a certain distance, and sealed and welded.

[0043] The longitudinal sections of the short-end shaft 21 and the long-end shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com