Super-hydrophobic glass fiber composite oil-water separation material and preparation method and application thereof

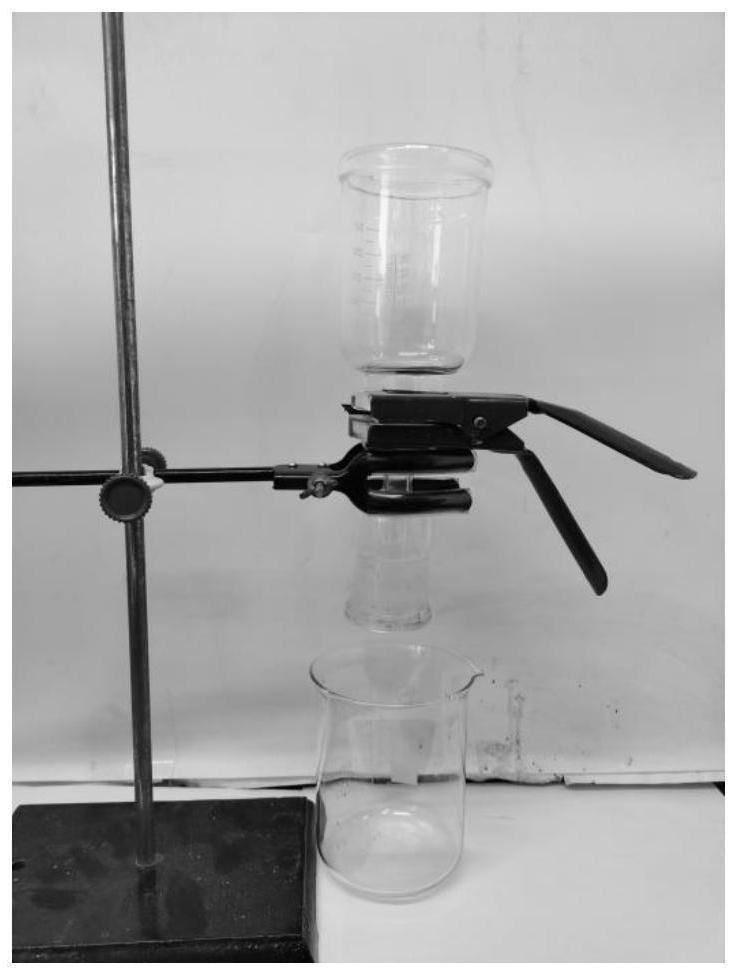

A super-hydrophobic glass fiber, oil-water separation technology, applied in semi-permeable membrane separation, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of poor filtration efficiency, service life of mixed fibers, and difficulty in use and promotion and other problems, to achieve good separation effect, improve hydrophobic and lipophilic performance, and good demulsification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Cut an appropriate amount of glass fiber mat, first use ethanol to ultrasonically clean the glass fiber mat for 10 minutes, then wash it with deionized water, and dry it in an oven at 60°C until it is completely dry;

[0040] (2) Dissolving 3g of basic copper carbonate in 250ml volume concentration of 30% ammonia solution, magnetically stirred for 30min until fully dissolved to obtain a basic copper carbonate-ammonia mixed solution;

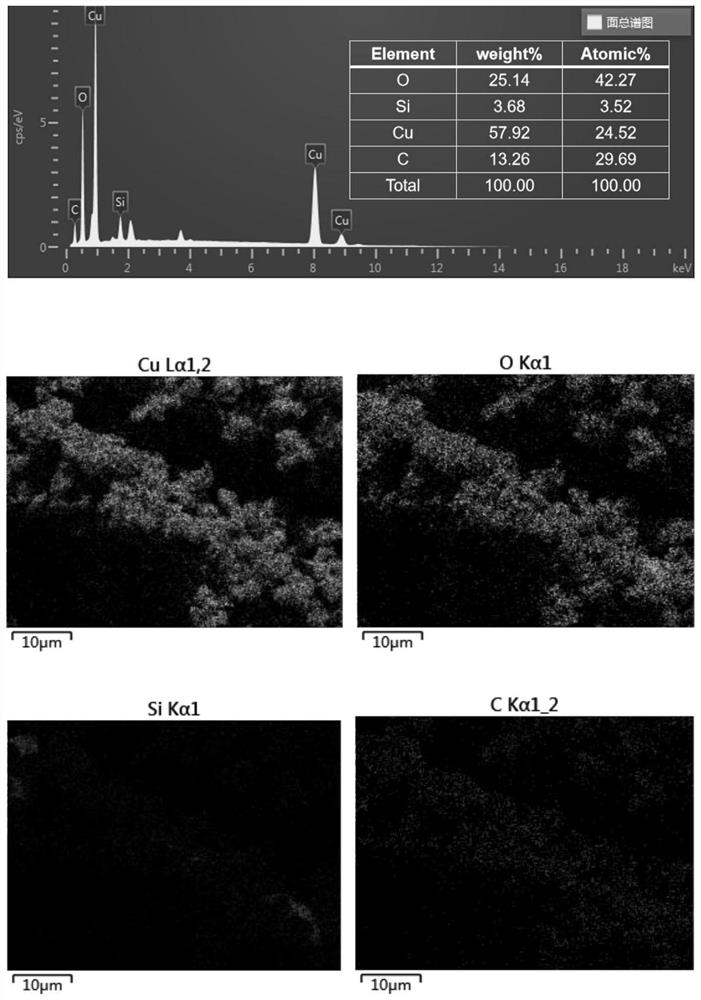

[0041] (3) Immerse the glass fiber mat cleaned and dried in step (1) in a mixed solution of basic copper carbonate-ammonia water, put it into a reaction vessel, and conduct a hydrothermal deposition reaction at 100°C for 30 minutes to obtain CuO@glass fiber mat; take it out For CuO@glass fiber mat, wash and clean the glass fiber mat with deionized water, and dry it in an oven at 60°C until it is completely dry;

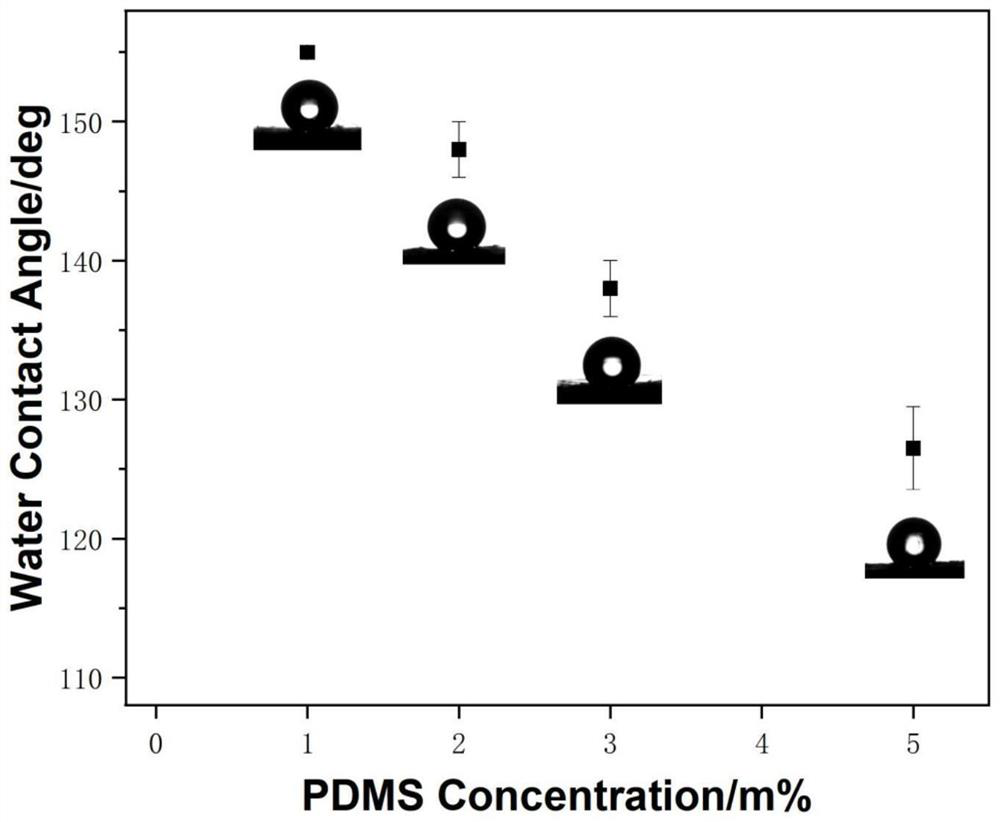

[0042] (4) Add 1 g of polydimethylsiloxane (PDMS) solution into 100 g of n-hexane solution, and stir magnetically for 30 min...

Embodiment 2

[0047] (1) Cut an appropriate amount of glass fiber felt, first use ethanol to ultrasonically clean the glass fiber composite material for 10 minutes, then wash it with deionized water, and dry it in an oven at 60°C until it is completely dry;

[0048] (2) 3g basic copper carbonate is dissolved in the 30% aqueous ammonia solution of 250ml, magnetically stirred 30min to dissolving completely, obtains basic copper carbonate-ammonia mixed solution;

[0049] (3) Immerse the glass fiber mat cleaned and dried in step (1) in a mixed solution of basic copper carbonate-ammonia water, put it into a reaction vessel, and conduct a hydrothermal deposition reaction at 100°C for 30 minutes to obtain CuO@glass fiber mat; take it out For CuO@glass fiber mat, wash and clean the glass fiber mat with deionized water, and dry it in an oven at 60°C until it is completely dry;

[0050] (4) Add 2 g of polydimethylsiloxane (PDMS) solution into 100 g of organic solvent n-hexane solution, and stir magne...

Embodiment 3

[0054] (1) Cut an appropriate amount of glass fiber felt, first use ethanol to ultrasonically clean the glass fiber composite material for 10 minutes, then wash it with deionized water, and dry it in an oven at 60°C until it is completely dry;

[0055] (2) 3g basic copper carbonate is dissolved in 30% aqueous ammonia solution of 250ml, magnetically stirred for 30min to completely dissolving, basic copper carbonate-ammonia mixed solution;

[0056] (3) Immerse the glass fiber mat cleaned and dried in step (1) in a mixed solution of basic copper carbonate-ammonia water, put it into a reaction vessel, and conduct a hydrothermal deposition reaction at 100°C for 30 minutes to obtain CuO@glass fiber mat; take it out For CuO@glass fiber mat, wash and clean the glass fiber mat with deionized water, and dry it in an oven at 60°C until it is completely dry;

[0057] (4) Add 5 g of polydimethylsiloxane (PDMS) solution into 100 g of organic solvent n-hexane solution, and stir magnetically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com