Water pipe pressing machine and method thereof

A technology of pressing machine and water pipe, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as increasing production cost and reducing work efficiency, and achieve the effect of saving production cost and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

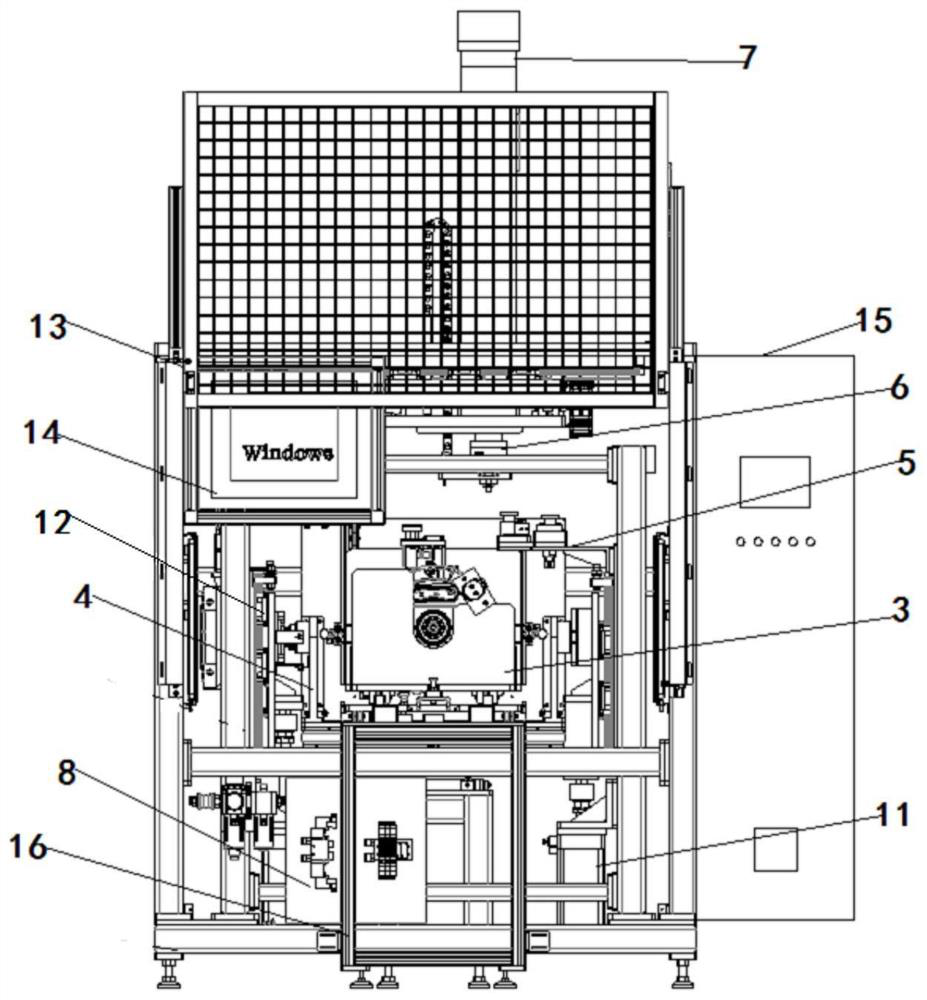

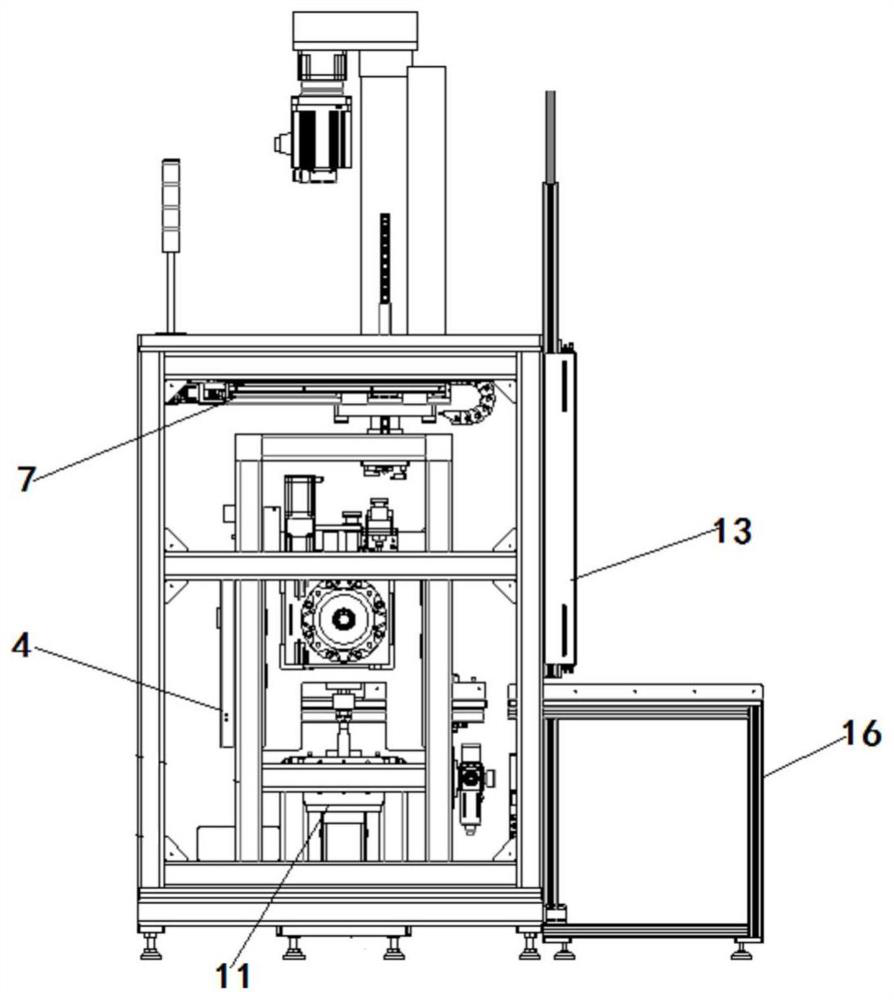

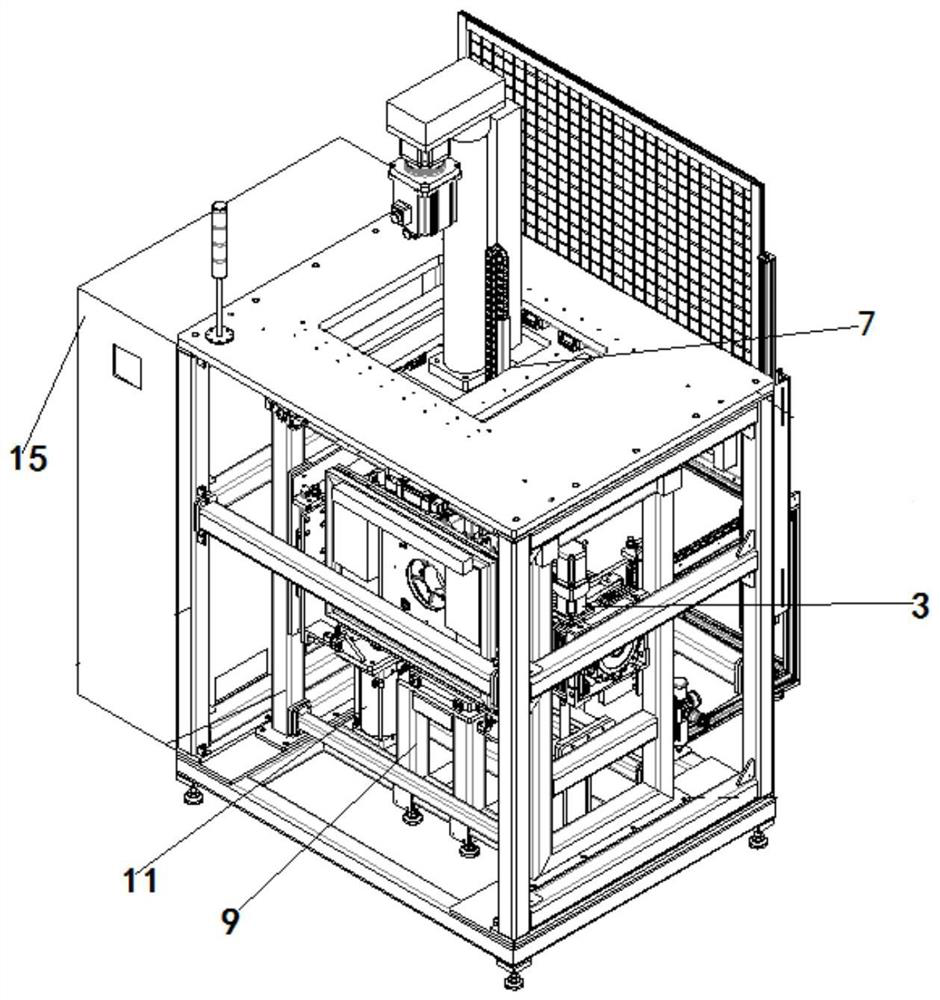

[0076] Embodiment: In the initial state, the motor positioning tool 3 is located on the loading workbench 16, and the operator lifts the motor and places the motor on the motor positioning tool 3, such as Figure 43 As shown, the motor is in a horizontal posture at this time, and then the motor is positioned and clamped. The operator installs the two water pipes into the indenter 17 respectively, places them on the indenter placement mechanism 5, and pushes the motor positioning tool 3 into the motor turning mechanism 4. Start the electric control cabinet 15 with the control panel, close the safety door 13, the motor overturning mechanism 4 uses the motor positioning sensor 4-10 to confirm that the motor positioning tooling 3 is in place, the lifting cylinder 11 drives the motor overturning mechanism 4 down, and the tooling positioning platform 9 passes through The hollow position of the motor turning mechanism 4 makes the motor positioning tooling 3 fall on the tooling positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com