3D printer material tray fixing device

A 3D printer and fixture technology, applied in 3D object support structures, accessories for processing main materials, manufacturing tools, etc., can solve the problem of increasing the effective and continuous conveying of wires, insufficient supply of hot-melt wires, and increasing wire resistance, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

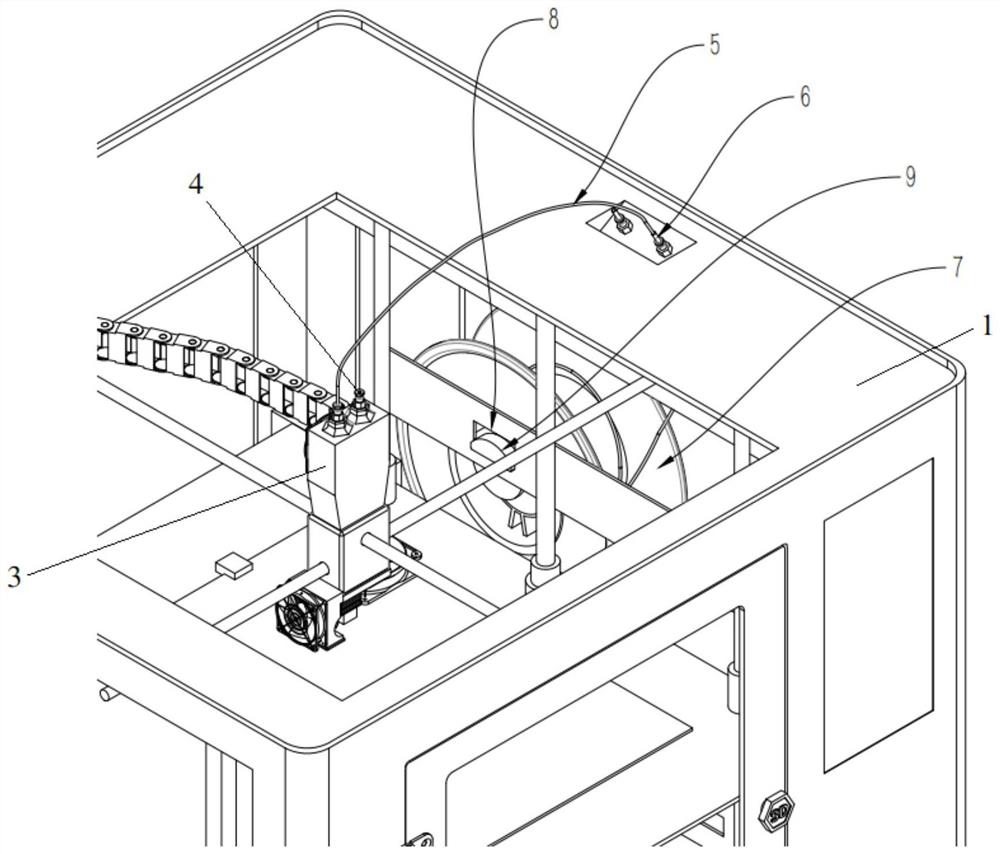

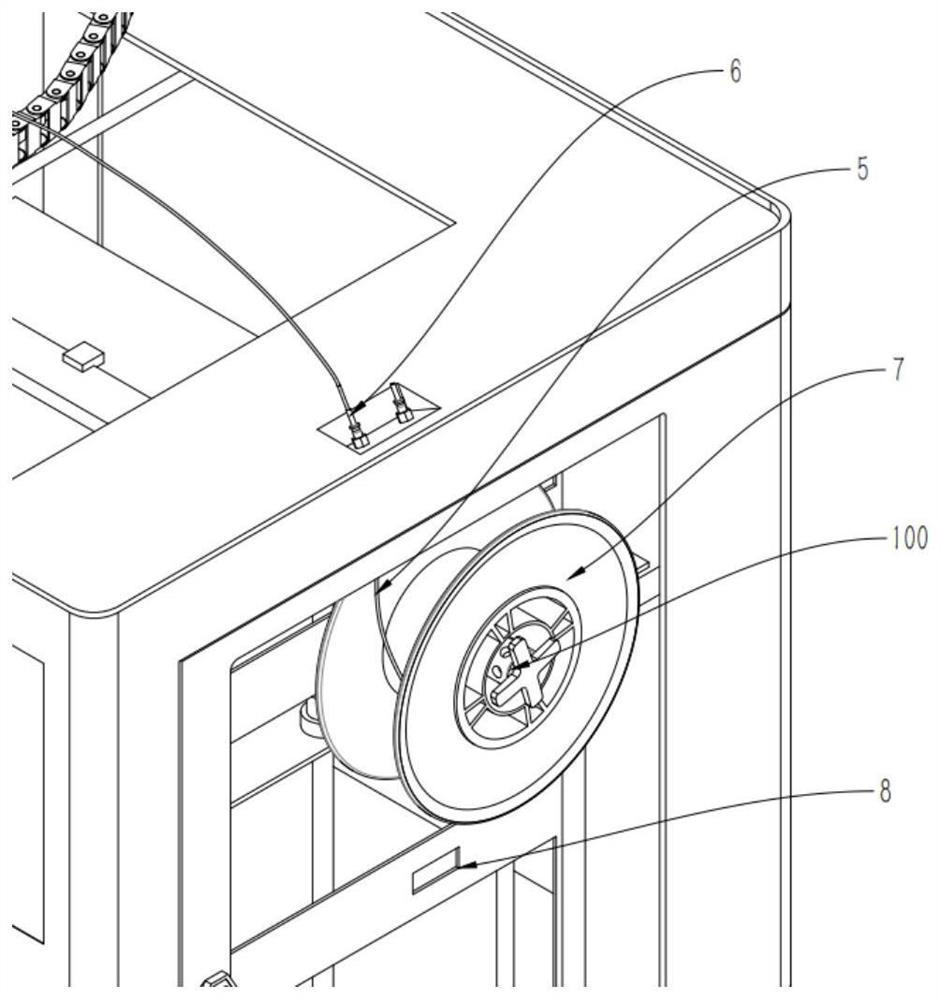

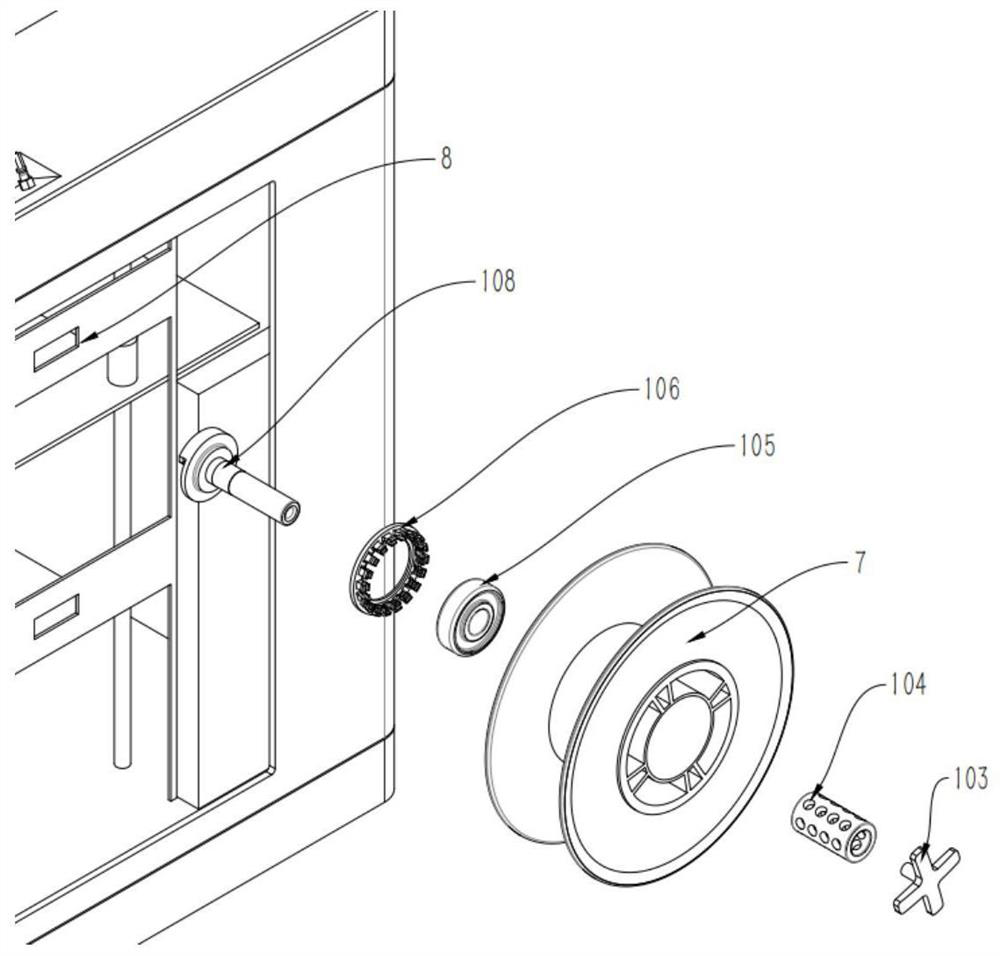

[0059] Such as figure 1 , a 3D printer model described, the material tray 7 used to store the printing wire 5 is directly suspended on the material rack 9, and the material rack 9 is hooked to the material rack mounting hole 8 on the side of the frame 1, and the wire material 5 is made of the material The disk protrudes, passes through the feed conduit 6 located on the right side of the frame 1, and then passes through the feed chute 4 located on the upper part of the feed device 3, along the guide tube in the feed device, through the print head material holder , the cooling device and the throat in the material spraying device, and finally through the high-temperature nozzles, they are continuously stacked on the printing platform located in the frame. On the transmission path of the printing wire 5, the influence of the matching of the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com