Sewage treatment system

A technology of sewage treatment system and air flotation tank, which is applied in water/sewage treatment, flotation water/sewage treatment, water/sewage treatment equipment, etc. It can solve the problems of difficult control of dissolved air tanks, achieve stable floc removal rate, The effect of simple control and stable floc content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention will be described in detail below in conjunction with specific embodiments.

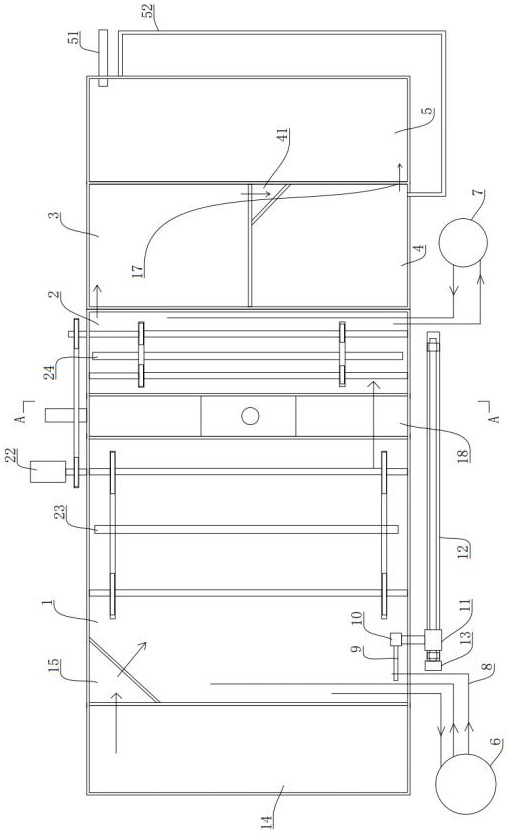

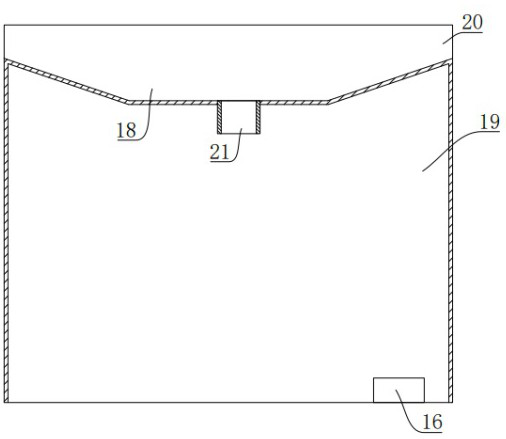

[0020] Such as Figure 1~Figure 2 , is an embodiment of the sewage treatment system of the present invention, specifically:

[0021] A sewage treatment system, comprising a main air flotation tank 1, an auxiliary air flotation tank 2, an anaerobic fermentation tank 3, an aerobic fermentation tank 4 and a sedimentation tank 5 connected in sequence, and also includes a main air-dissolving tank 6 and an auxiliary air-dissolving tank 7, The main air flotation tank 1 and the secondary air flotation tank 2 are communicated with the main dissolved air tank 6 and the secondary dissolved air tank 7 respectively, and the volume of the secondary air flotation tank 2 is 10-35% of the volume of the main air flotation tank 1. The gas volume is mainly 5-35% of the dissolved gas capacity of the dissolved gas tank 6.

[0022] After the flocculant is added to the sewage, most of the flocs produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com