Testbed suitable for reliability test of lubricating oil pump of gas turbine and test method

A technology for gas turbines and lubricating oil pumps, which can be used in pump testing, mechanical equipment, machines/engines, etc., and can solve problems such as large investment in human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

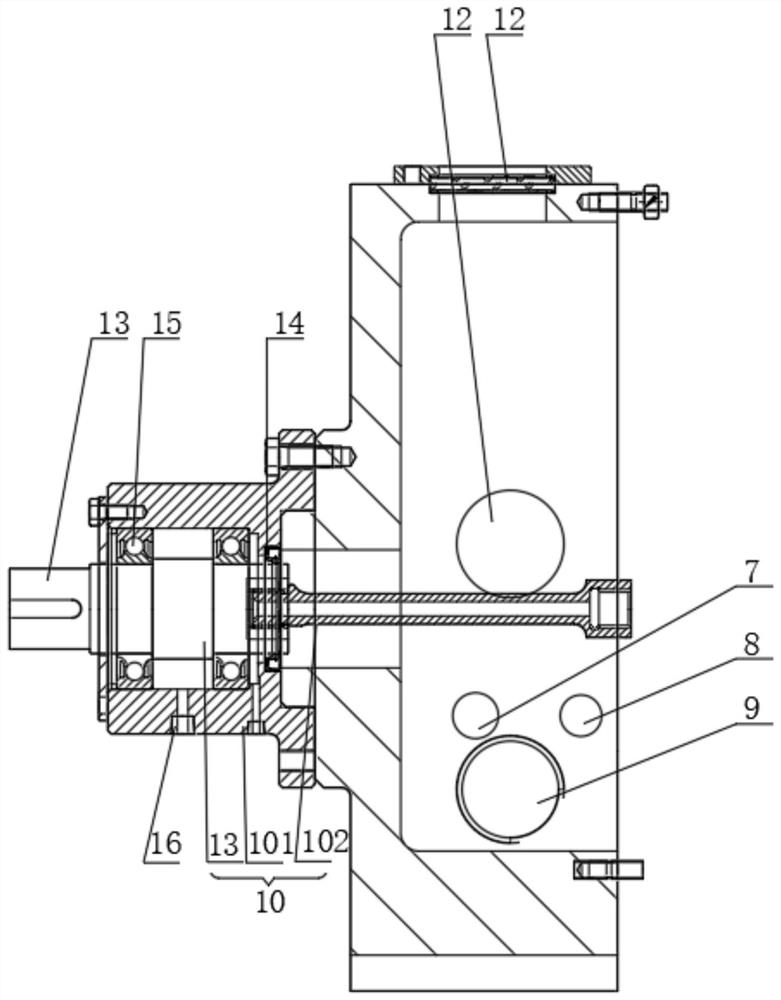

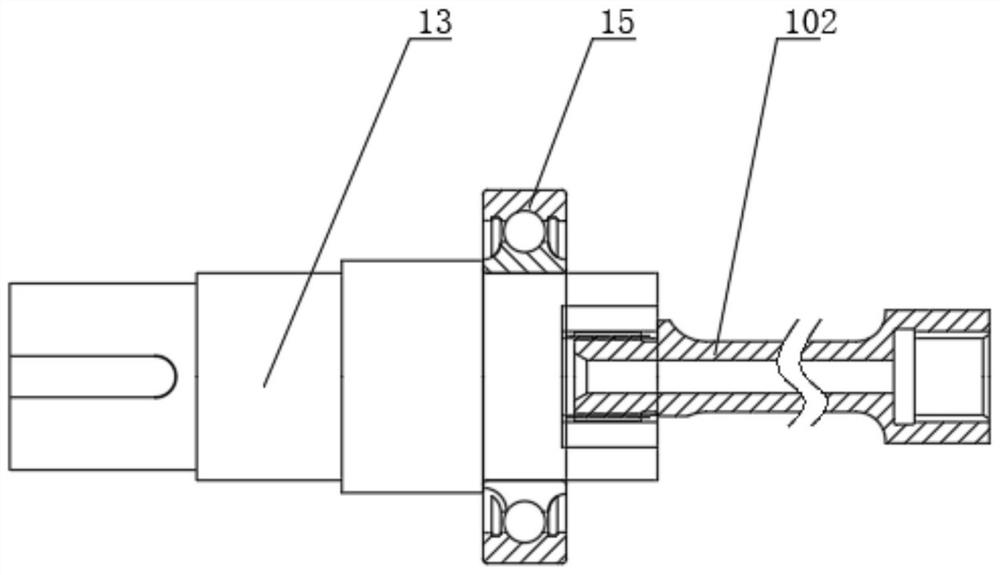

[0045] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

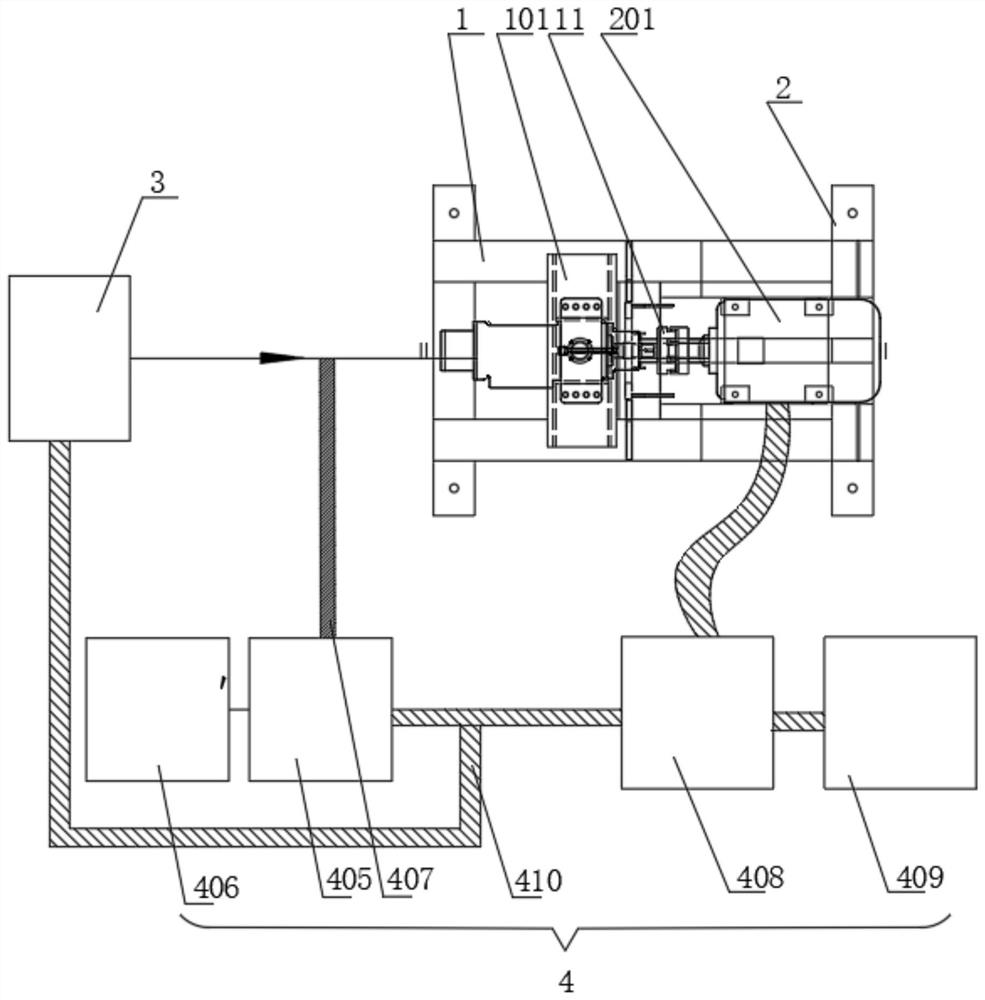

[0046] Such as Figure 1-Figure 6 As shown, the test bench suitable for the reliability test of the gas turbine lubricating oil pump in this embodiment includes an underframe 1 and a drive test system 2 installed on the underframe 1, and the drive test system 2 is connected with a hydraulic pipe for delivering oil Road system 3. Measurement and control system for real-time monitoring of equipment operation status 4,

[0047] The driving test system 2 includes a variable frequency motor 201 on the chassis 1, a lubricating oil pump 5 driven by the variable frequency motor 201,

[0048] The hydraulic pipeline system 3 includes an internally heated lubricating oil tank 301, an oil suction pipe group connected between the lubricating oil tank 301 and the lubricating oil pump 5, and an oil return pipeline 302 is connected between the oil outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com