Ultrasonic scanning device

A scanning device and ultrasonic technology, applied in the field of nuclear power, can solve the problems of complex installation position, thin wall thickness, inaccurate positioning, etc., and achieve the effect of stable movement trajectory, accurate defect positioning, and reduction of human errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0035] The method can be executed by a terminal device. For example, the terminal device can be a server, a desktop computer, a notebook computer, a tablet computer, etc., and the terminal device can also be, for example, a user device, a vehicle-mounted device, or a wearable device. The type of is not limited.

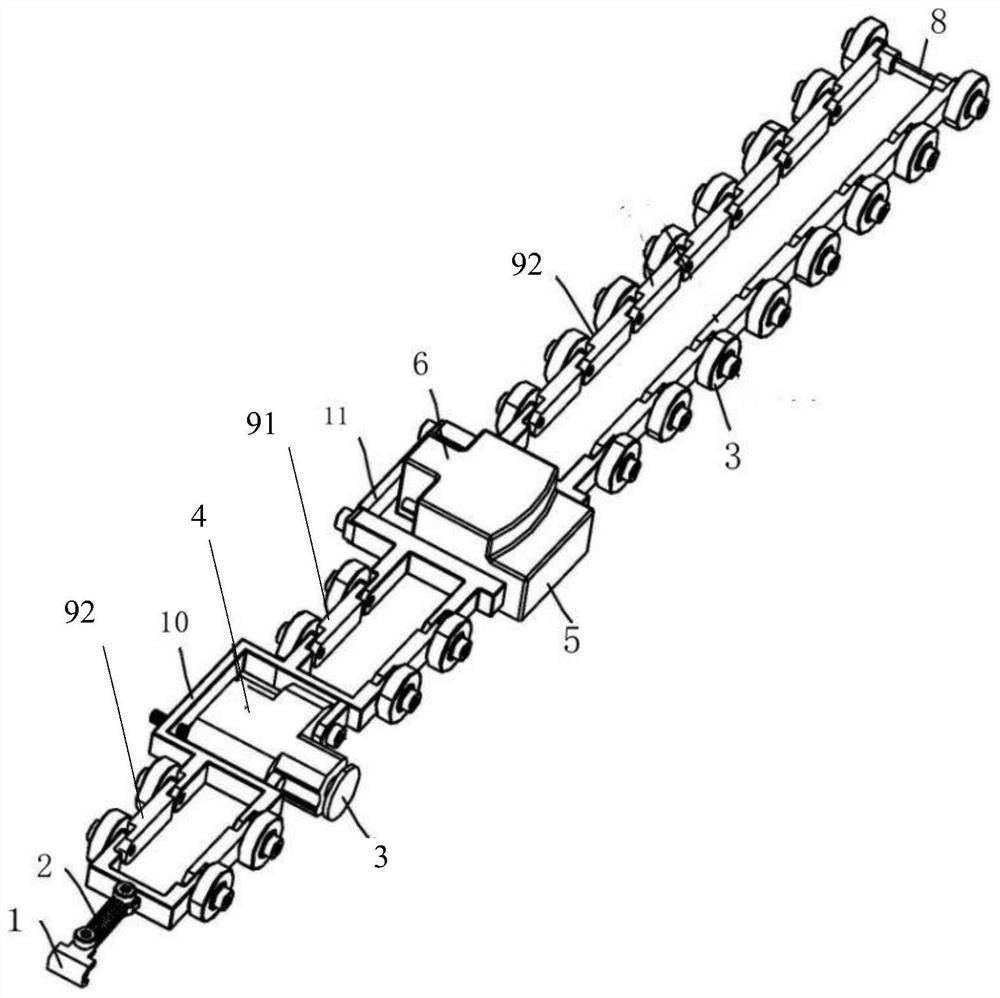

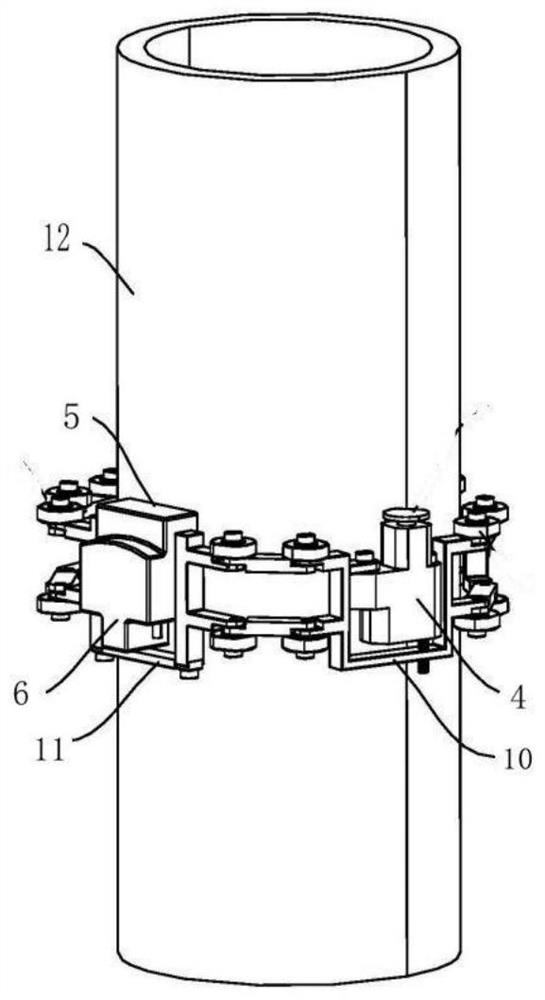

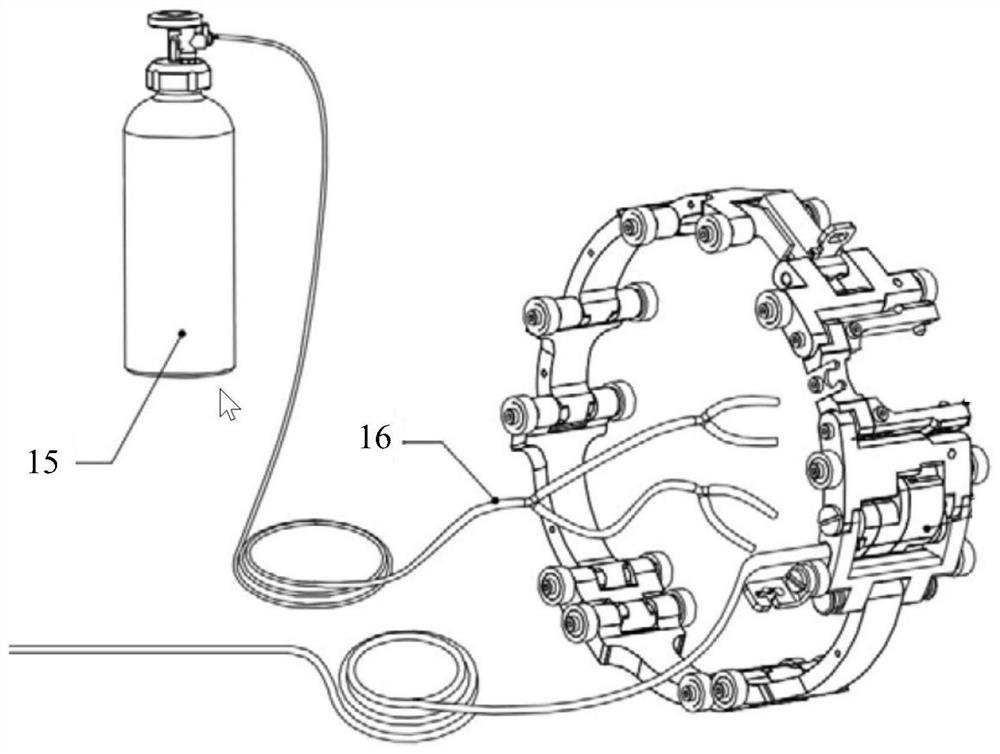

[0036] figure 1 and figure 2 It is a perspective view of an ultrasonic scanning device according to an exemplary embodiment. image 3 It is a schematic diagram showing an ultrasonic scanning device in use according to an exemplary embodiment. Such as Figure 1 to Figure 3 As shown, the ultrasonic phased array scanning device includes: a first chain 91, a second chain 92, a plurality of rollers 3, an ultrasonic probe 6 and an encoder 4;

[0037] Both sides of the first chain 91 and the second chain 92 are respectively be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com