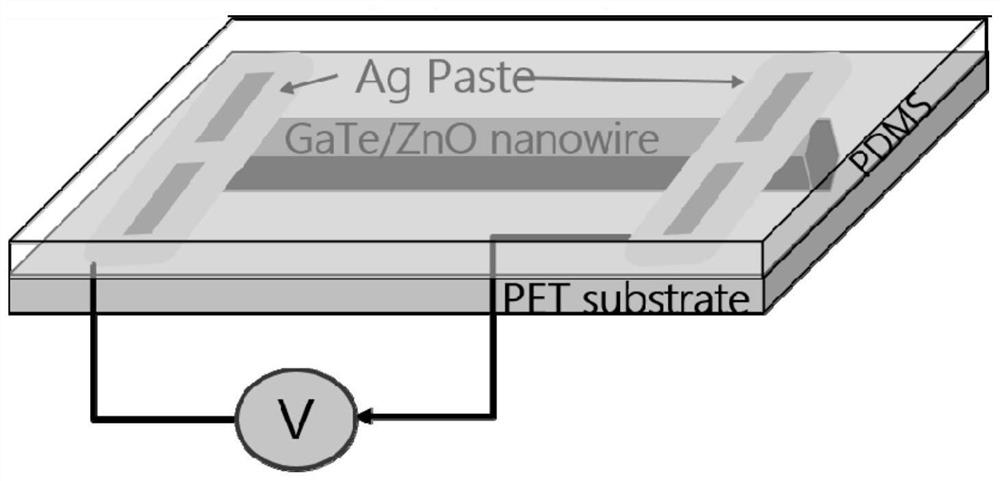

GaTe/ZnO-based micro generator and preparation method thereof

A micro-generator and electrode technology, which is applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, piezoelectric/electrostrictive device manufacturing/assembly, etc., can solve the problem of high cost, Low output power and other issues, to achieve the effect of low cost, high output power, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a GaTe / ZnO-based micro-generator, comprising the following steps in turn:

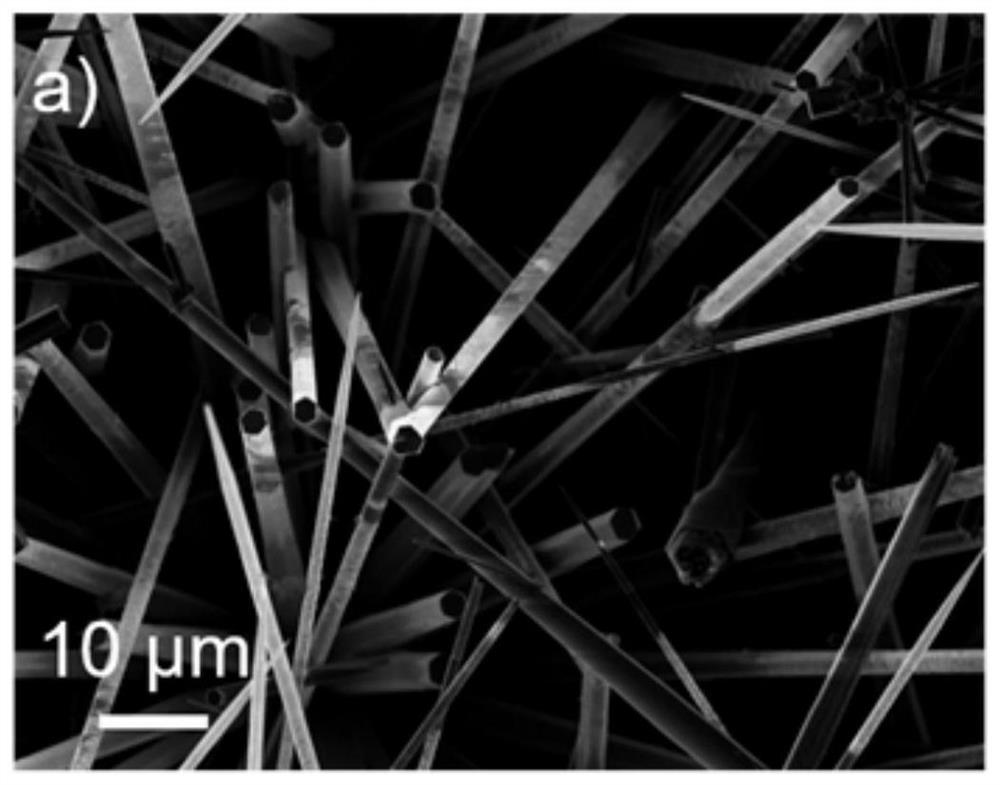

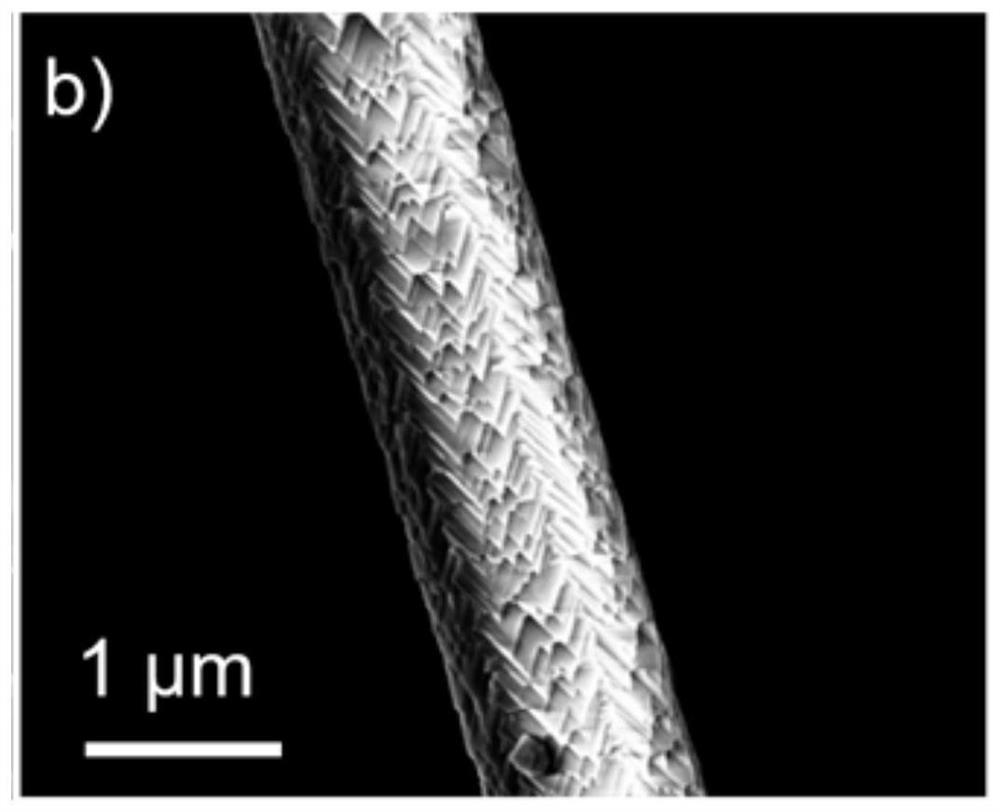

[0045] (1) Preparation of microwire components: ZnO microwires are formed on a metal substrate by chemical vapor deposition as a precursor structure; then a GaTe film is formed on the ZnO microwires by chemical vapor deposition, and the GaTe film is arranged on the ZnO microwires.

[0046] Before forming the precursor structure, the metal substrate is washed with acetone and absolute ethanol in sequence, and the surface of the metal substrate is treated with plasma. The plasma treatment in this embodiment can be cleaned with a nitrogen gun. The metal substrate in this embodiment is a silicon substrate.

[0047] a. Forming ZnO micron wires specifically includes the following steps in sequence:

[0048] Fix the metal substrate upside down on the quartz ark, place 6mg of evaporation source Zn on the quartz ark, then put the quartz ark into the tube furnace for chemical vapor...

Embodiment 2

[0066] A method for preparing a GaTe / ZnO-based micro-generator, comprising the following steps in turn:

[0067] (1) Preparation of microwire components: ZnO microwires are formed on a metal substrate by chemical vapor deposition as a precursor structure; then a GaTe film is formed on the ZnO microwires by chemical vapor deposition, and the GaTe film is arranged on the ZnO microwires.

[0068] Before forming the precursor structure, the metal substrate is washed with acetone and absolute ethanol in sequence, and the surface of the metal substrate is treated with plasma. The plasma treatment in this embodiment can be cleaned with a nitrogen gun. The metal substrate in this embodiment is a silicon substrate.

[0069] a. Forming ZnO micron wires specifically includes the following steps in sequence:

[0070] Fix the metal substrate upside down on the quartz ark, place 10mg of evaporation source Zn on the quartz ark, then put the quartz ark into a tube furnace for chemical vapor ...

Embodiment 3

[0088] A method for preparing a GaTe / ZnO-based micro-generator, comprising the following steps in turn:

[0089] (1) Preparation of microwire components: ZnO microwires are formed on a metal substrate by chemical vapor deposition as a precursor structure; then a GaTe film is formed on the ZnO microwires by chemical vapor deposition, and the GaTe film is arranged on the ZnO microwires.

[0090] Before forming the precursor structure, the metal substrate is washed with acetone and absolute ethanol in sequence, and the surface of the metal substrate is treated with plasma. The plasma treatment in this embodiment can be cleaned with a nitrogen gun. The metal substrate in this embodiment is a silicon substrate.

[0091] a. Forming ZnO micron wires specifically includes the following steps in sequence:

[0092] Fix the metal substrate upside down on the quartz ark, place 8mg of evaporation source Zn on the quartz ark, then put the quartz ark into a tube furnace for chemical vapor d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap