Silicone composition and its application as an additive in detergent composition to enhance foamability and cleaning effect

A silicone composition and composition technology, applied in the preparation of detergent compositions, detergent compounding agents, detergent mixture compositions, etc., can solve the problems of no description and reduction of active ingredients in detergent compositions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

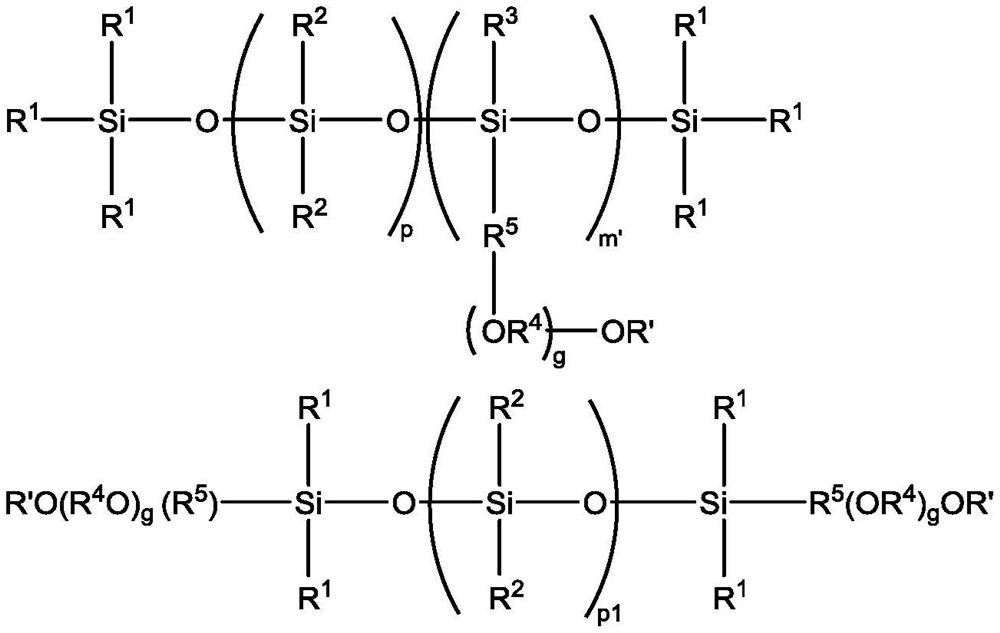

Method used

Image

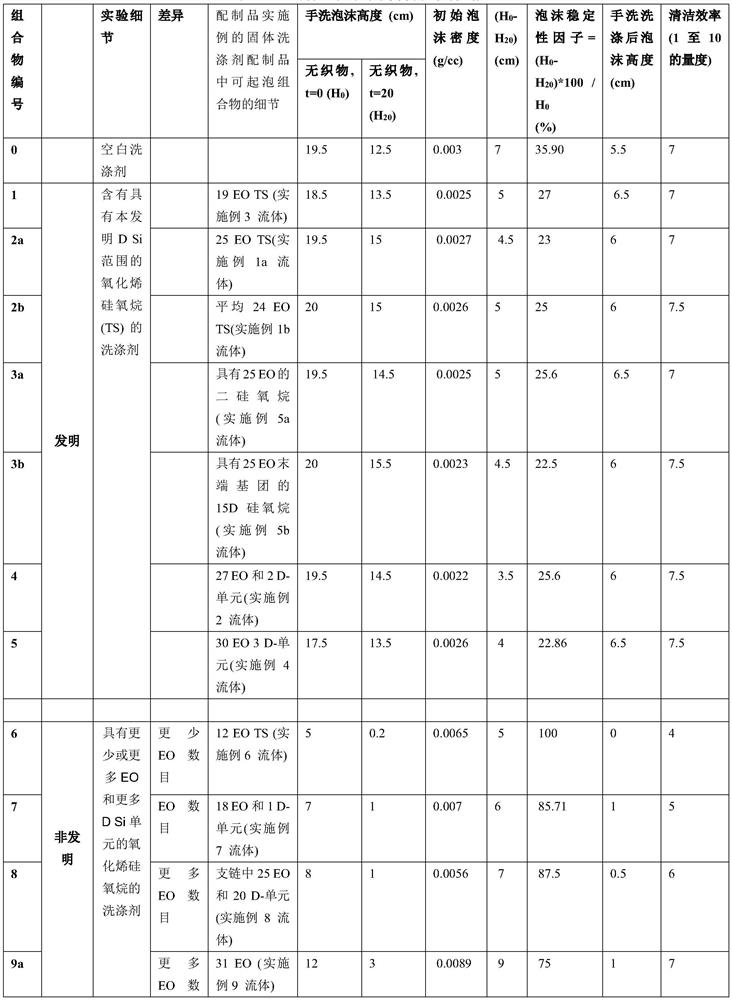

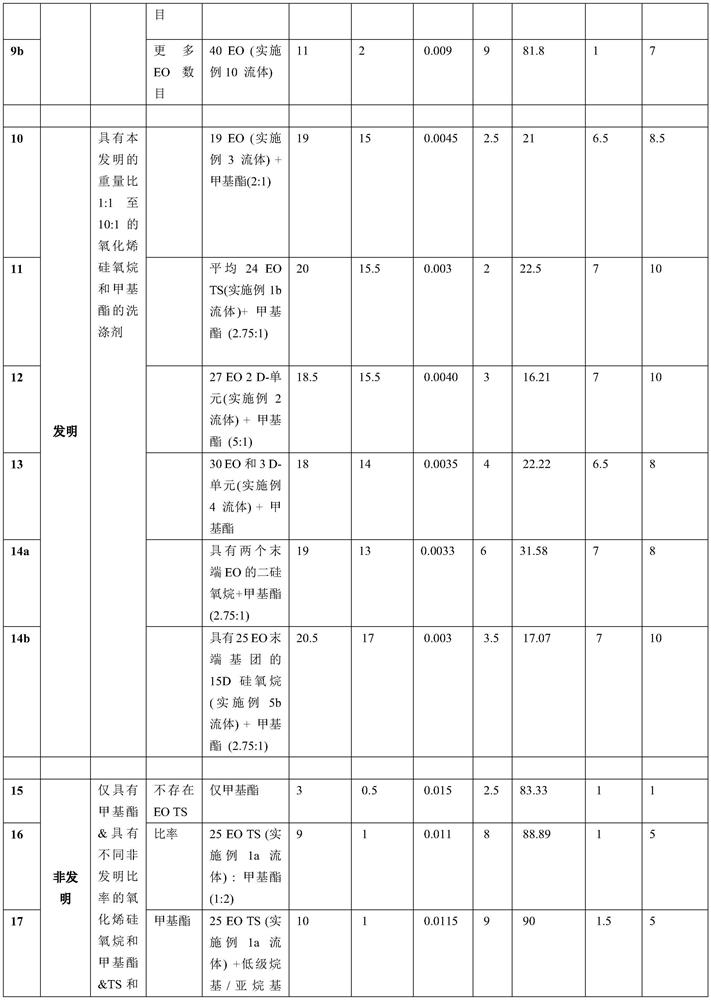

Examples

preparation example Construction

[0078] In the preparation step of the siloxane used in the silicone composition, in the second step of the process of the invention, allyloxy (polyethylene oxide) (available under the Polymeg trademark from IGL, India).

[0079] Allyloxy (polyoxyethylene) or ethylenically unsaturated polyethers are preferably selected from polyethylene glycol allyl methyl ether CH 2 =CHCH 2 (OC 2 h 4 ) n OH; CH 2 =CHCH 2 (OC 3 h 6 ) n OH; polyalkylene glycol allyl methyl ether (EO / PO random) CH 2 =CHCH 2 O(C 2 h 4 O) l (C 3 h 6 O) k H, where l and k are an integer of 2 to 100, preferably 19 to 40, and more preferably 19 to 30. A non-limiting example of a preferred ethylenically unsaturated polyether is allyloxy(polyethylene oxide) (EO 25) available under the Polymeg trademark from IGL, India. The ethylenically unsaturated polyethers are used in an amount of 1 to 1.1 mol of ethylenically unsaturated groups (C=C) in the polyether per 1 mol of Si-bonded hydrogen in the hydrosilo...

Embodiment 1a

[0116] Example 1a) Preparation of 25-polyoxyalkylene-siloxane (according to the invention):

[0117] step 1 – Synthesis of H-siloxane: 1500g of Wacker H-siloxane (hydrogen concentration of 1.6%, ie 24 moles of H), 4192g of disiloxane (Wacker DM 0 65) (25.88 moles) and PNCl of 200ppm 2 The catalyst is loaded into the SS reactor, the set temperature is 105°C, the temperature is overshot to 110-115°C, and the set temperature is 108-110°C. The reaction was continued for 4 hours, and then the distillation was started at 180° C. in temperature increments of 5° C. (2 h for 10 lt reactor time for complete distillation to obtain the rearranged H-siloxane. The yield was 75% to 80 % of rearrangement products rearranged H-siloxane.

[0118] step 2- Synthesis of polyoxyalkylene silicones: 1800 g of rearranged H-siloxane (6.081 moles) (from step 1) and raising the temperature in the reactor to 100-102°C. The reactor is equipped with controlled agitation and heating and has facilities...

Embodiment 1b

[0119] Example 1b) Preparation of average 24-polyoxyalkylene-siloxane (according to the invention):

[0120] step 1 – Synthesis of H-siloxane: 1500g of Wacker H-siloxane (hydrogen concentration of 1.6%, ie 24 moles of H), 4192g of disiloxane (Wacker DM 0 65) (25.88 moles) and PNCl of 200ppm 2 The catalyst is loaded into the SS reactor, the set temperature is 105°C, the temperature is overshot to 110-115°C, and the set temperature is 108-110°C. Continue the reaction for 4 hours, then start to distill at 180° C. with temperature increments of 5° C. (2 h for a 10 lt reactor for complete distillation to obtain rearranged H-siloxanes, and then dissolve the catalyst in soda powder and Rearranged H-siloxanes with yields of 75% to 80% of rearranged products.

[0121] step 2 - Synthesis of polyoxyalkylene silicones: 1800 g of rearranged H-siloxane (6.081 moles) (from step 1) and raising the temperature in the reactor to 100-102°C. The reactor is equipped with controlled agitatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com