Efficient sand screening device for water conservancy project construction

A technology for water conservancy projects and screening equipment, which is applied in the fields of screening, solid separation, chemical instruments and methods, etc., and can solve the problems of reducing the practicability of sand screening devices, reducing sand quality, and simple structure of sand screening devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

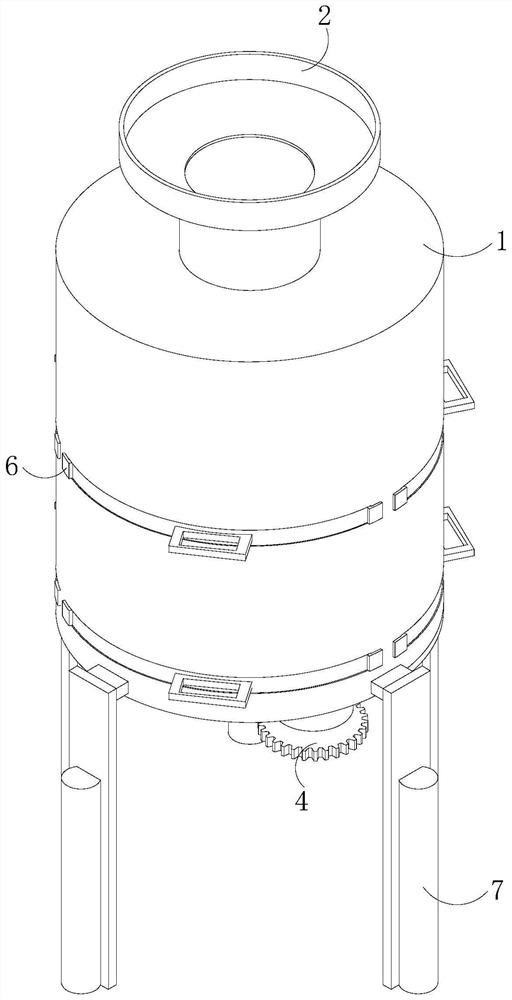

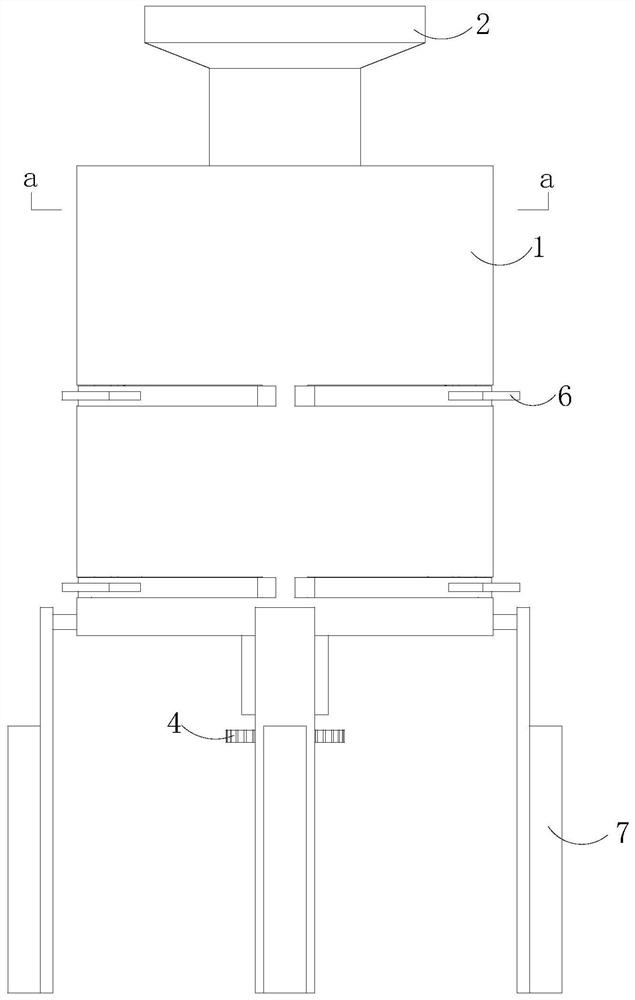

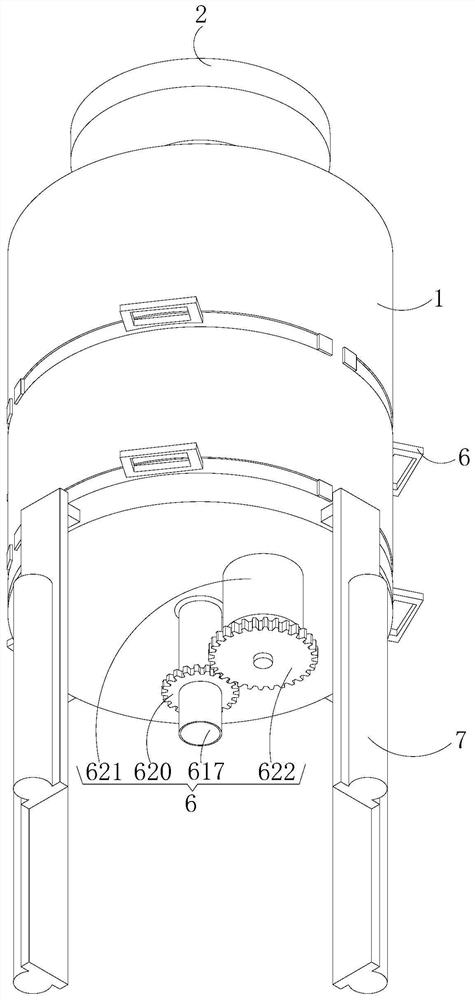

[0038] see Figure 1-13 , the present invention provides a technical solution for high-efficiency sand screening equipment for water conservancy construction: a high-efficiency sand screening equipment for water conservancy construction, including a body 1, a guide hopper 2, a dispersion rod 3, a heavy screening Mechanism 4, anti-blocking mechanism 5, double screening mechanism 6 and supporting legs 7, the bottom end of the guide hopper 2 communicates with the middle part of the top surface of the body 1, and the ends of the dispersing rods 3 away from each other are fixedly connected to the inner wall of the bottom end of the guide hopper 2 respectively , the top of the primary screening mechanism 4 is fixedly connected to the end of the dispersing rod 3 that is close to each other, the top of the anti-blocking mechanism 5 is fixedly connected to the i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com