Cold core manufacturing process and device

A core-making device and cold core technology, applied in the direction of manufacturing tools, cores, metal processing equipment, etc., can solve the problems of sand washing, sand sintering, etc., to improve the strength of sand cores, reduce assembly labor intensity, and improve casting defects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

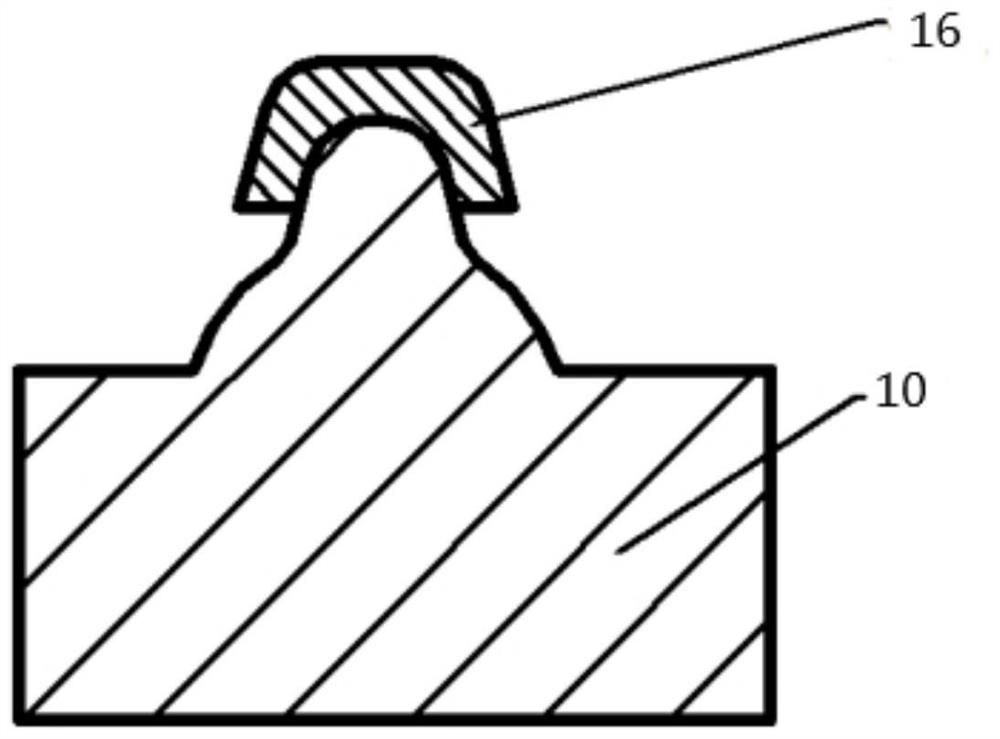

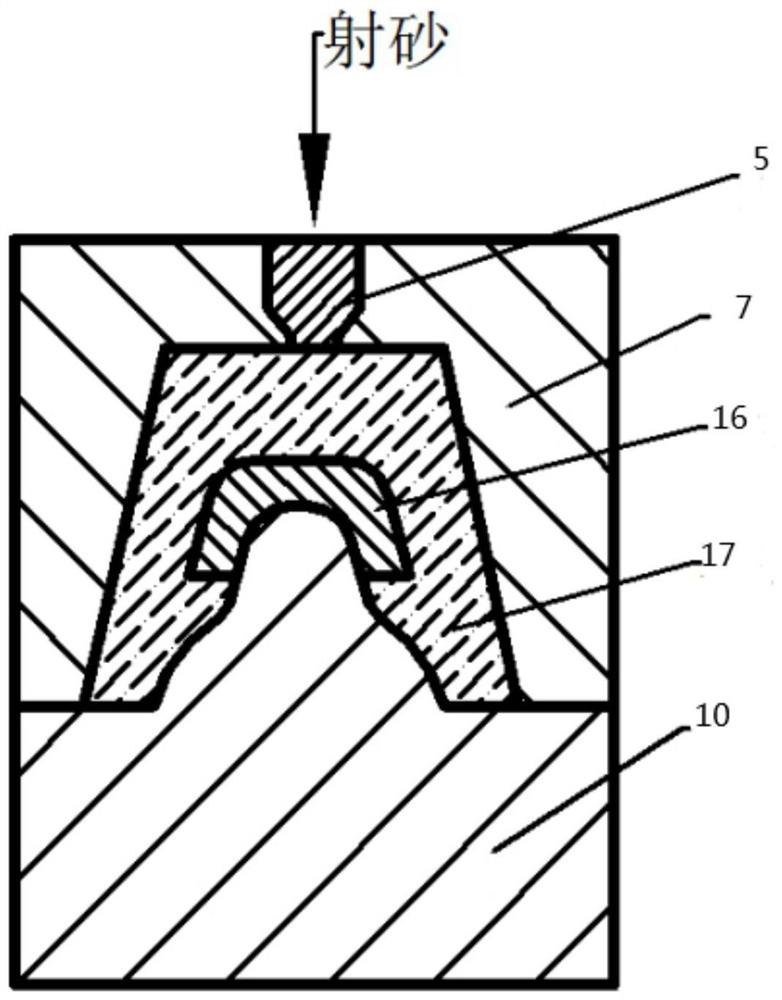

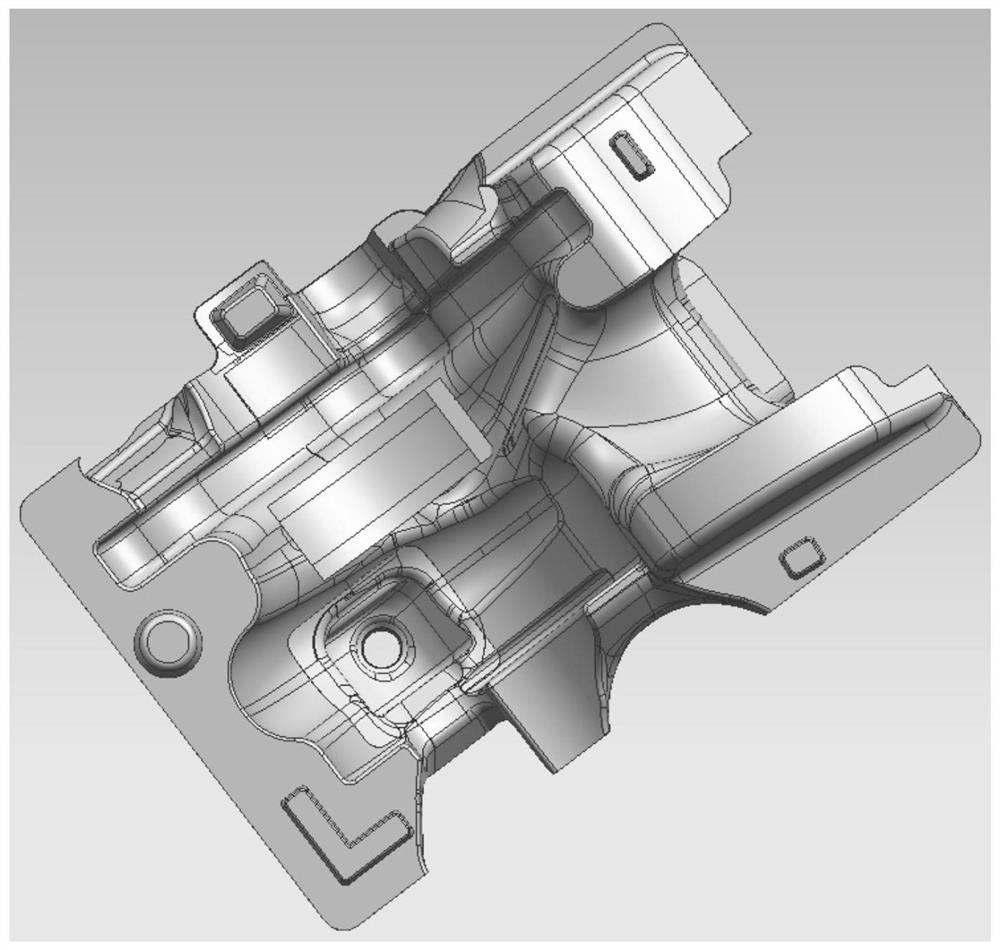

[0035] This embodiment provides a cold core core-making process, which is completed by using a hot core 16 and a cold core box, such as Figure 1-2 shown. A mold cavity is formed in the cold box, and the process includes: inserting a hot core 16 at a designated position of the mold cavity; injecting cold core sand 17 into the mold cavity where the hot core 16 is placed; After the sand 17 wraps the hot core 16, solidify gas is blown into the mold cavity; after the cold core sand 17 solidifies, the sand core is taken out. Sand core products such as image 3 shown. A new cold core making process disclosed by the invention is suitable for improving the quality of casting cold core molds, can effectively improve the quality of sand cores at specific positions, reduce the rate of casting rejects, reduce work intensity, and solve the problems in the current traditional cold core process. Sand core quality problems.

[0036] Described cold core box comprises upper core box 7 and l...

Embodiment 2

[0044] like Figure 4-10 , this embodiment provides a cold core core making device, including an upper mold part and a lower mold part, the upper mold part includes an upper core box 7, an air blowing plate 1, and a sand shooting plate 4, and the air blowing plate 1 And the sand shot plate 4 can move above the upper core box 7; the lower mold part includes a lower core box 10, a lower bottom frame 15, and a lower top plate 13, and the lower core box 10 is placed above the lower bottom frame 15, and the The lower top plate 13 is placed at the bottom of the lower core box 10; when the upper core box 7 and the lower core box 10 are connected together, a cavity is formed, and a designated position is preset in the cavity for placing the thermal core 16 .

[0045] The side of the upper core box 7 facing the lower core box 10 is provided with three guide sleeves 8, wherein one guide sleeve 8 is arranged in the middle of one side, and the other two guide sleeves 8 are arranged at opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com