A method for improving the strength of mnzn power ferrite core without increasing loss

A ferrite core, ferrite technology, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, circuit, etc., can solve the problem that the method is not perfect, and achieve the effect of improving the strength of the magnetic core

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

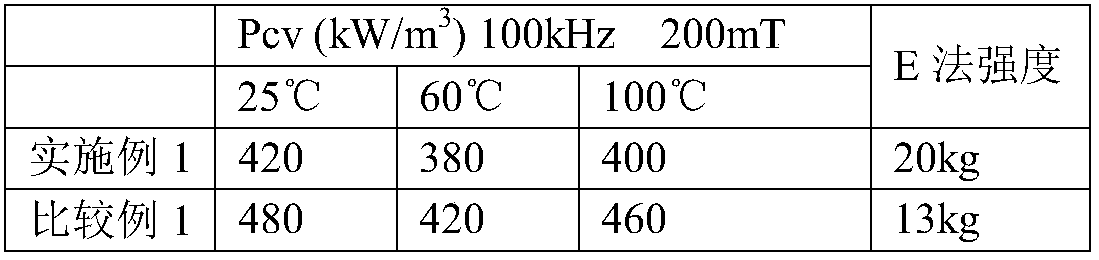

Embodiment 1

[0020] 53.5mol% Fe 2 o 3 and 10.2mol% of ZnO, the rest is the amount of MnO, mixed in the ratio of 1:4:0.45 according to the ratio of ball water, sand milling and crushing in a sand mill for 1 hour, then spray granulation, put into Pre-fired at 950°C in a rotary kiln. 400ppm of CaCO 3 , 100ppm ZrO 2 and 350ppm V 2 o 5 Add it to the calcined material, put the calcined material and additives into a sand mill, grind it for 160 minutes, then spray and granulate it, and press it into ECW32G2 product under a certain pressure. Put the product into a bell furnace for sintering, and the sintering temperature is 1300°C. Keep warm for 5 hours, and the oxygen content is 5%-6%. Then cooled to room temperature under nitrogen protection.

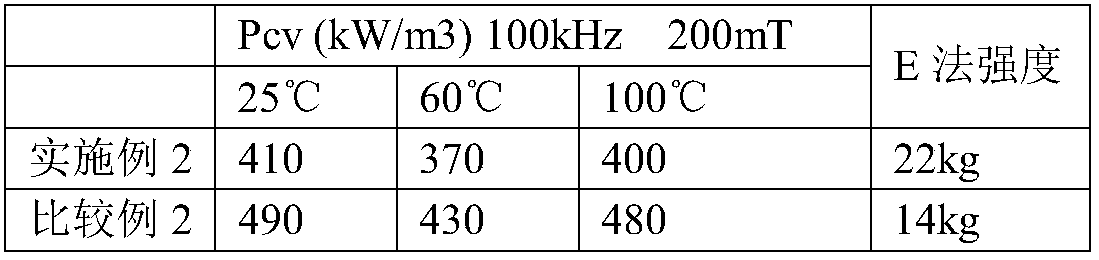

Embodiment 2

[0027] 53.2mol% Fe 2 o 3 and 10.5mol% of ZnO, and the rest is the amount of MnO, mixed according to the ratio of 1:4:0.45 in the ratio of ball water to water, sanded and crushed in a sand mill for 1 hour, then spray granulated, put into Pre-fired at 950°C in a rotary kiln. 300ppm of CaCO 3 , 100ppm ZrO 2 and 350ppm V 2 o 5 Add it to the calcined material, put the calcined material and additives into a sand mill, grind it for 160 minutes, then spray and granulate it, and press it into ECW32G2 product under a certain pressure. Put the product into a bell furnace for sintering, and the sintering temperature is 1300°C. Keep warm for 5 hours, and the oxygen content is 5%-6%. Then cooled to room temperature under nitrogen protection.

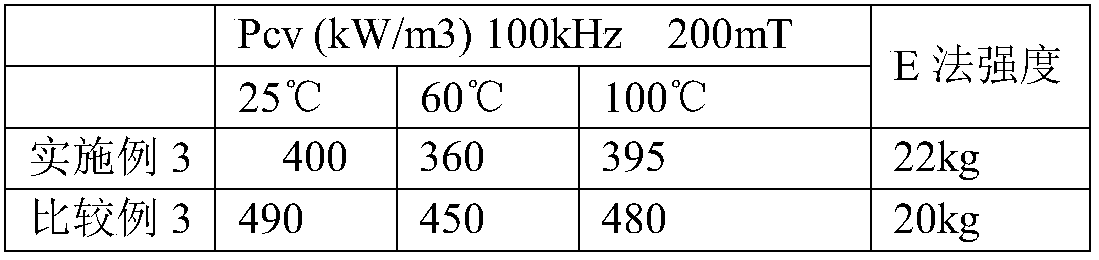

Embodiment 3

[0034] 53mol% Fe 2 o 3 and 10.7mol% of ZnO, the rest is the amount of MnO, mixed in the ratio of 1:4:0.45 according to the ratio of ball water, sand milled and crushed in a sand mill for 1 hour, then spray granulated, put into Pre-fired at 950°C in a rotary kiln. 300ppm of CaCO 3 , 100ppm ZrO 2 and 240ppm V 2 o 5 Add it to the calcined material, put the calcined material and additives into a sand mill, grind it for 160 minutes, then spray and granulate it, and press it into ECW32G2 product under a certain pressure. Put the product into a bell furnace for sintering, and the sintering temperature is 1300°C. Keep warm for 5 hours, and the oxygen content is 5%-6%. Then cooled to room temperature under nitrogen protection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com