Roller sleeve of a roller press and manufacturing method thereof

A manufacturing method and technology of roller presses, applied in the field of roller presses, can solve problems affecting production efficiency and operating costs, prone to cracks in the surface surfacing layer, and affecting the use efficiency of roller presses, etc., to achieve high toughness and hardness High and long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

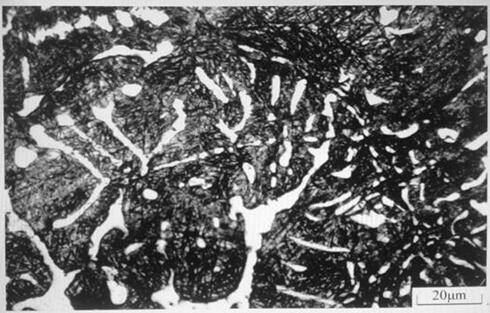

[0057] A roller press roller sleeve, the roller sleeve includes an outer working layer, an inner core, and a transition layer between the working layer and the core; the working layer is made of high-speed steel, and the transition layer is made of It is semi-steel, and the material of the core is medium carbon alloy steel.

[0058] The chemical composition of the working layer and the mass percentage of each composition are C 0.8%, Si 0.3%, Mn 0.1%, Cr 6%, W 3%, V 8%, Ni 0.6%, Mo 5%. The chemical composition of the transition layer and the mass percentage of each composition are C1.2%, Si 1.8%, Mn 0.5%, Cr 1.2%, V 0.1%, Ni 1.0%, Mo 0.2%. The chemical composition of the core and the mass percentage of each composition are C 0.25%, Si 0.6%, Mn 0.6%, Cr 0.5%, V 0.1%, Ni 1.0%, Mo 0.2%.

[0059] A method for preparing the roller sleeve of the above-mentioned roller press, comprising the following processes:

[0060] A. molten steel smelting

[0061] A1. According to the requir...

Embodiment 2

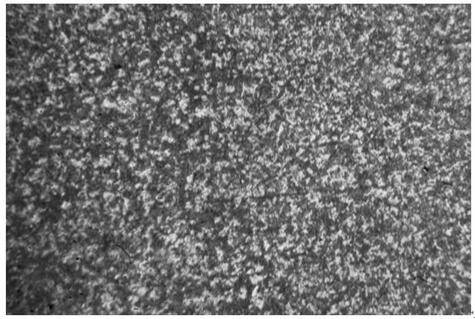

[0075] A roller press roller sleeve, the roller sleeve includes an outer working layer, an inner core, and a transition layer between the working layer and the core; the working layer is made of high-speed steel, and the transition layer is made of It is semi-steel, and the material of the core is medium carbon alloy steel.

[0076] The chemical composition of the working layer and the mass percentage of each composition are C 2.2%, Si 0.1%, Mn 0.2%, Cr 4%, W 5%, V 4%, Ni 1.5%, Mo 3%. The chemical composition of the transition layer and the mass percentage of each composition are C2.0%, Si 0.8%, Mn 1.0%, Cr 0.6%, V 0.2%, Ni 0.4%, Mo 0.6%. The chemical composition of the core and the mass percentage of each composition are C 0.50%, Si 0.2%, Mn 1.0%, Cr 0.3%, V 0.3%, Ni 0.4%, Mo0.6%.

[0077] A method for preparing the roller sleeve of the above-mentioned roller press, comprising the following processes:

[0078] A. molten steel smelting

[0079] A1. According to the requireme...

Embodiment 3

[0093] A roller press roller sleeve, the roller sleeve includes an outer working layer, an inner core, and a transition layer between the working layer and the core; the working layer is made of high-speed steel, and the transition layer is made of It is semi-steel, and the material of the core is medium carbon alloy steel.

[0094] The chemical composition of the working layer and the mass percentage of each composition are C 1.5%, Si 0.2%, Mn 0.15%, Cr 5%, W 4%, V 6%, Ni 1.1%, Mo 4%. The chemical composition of the transition layer and the mass percentage of each composition are C1.6%, Si 1.2%, Mn 0.8%, Cr 0.9%, V 0.15%, Ni 0.7%, Mo 0.4%. The chemical composition of the core and the mass percentage of each composition are C 0.35%, Si 0.4%, Mn 0.8%, Cr 0.4%, V 0.2%, Ni 0.7%, and Mo 0.4%.

[0095] A method for preparing the roller sleeve of the above-mentioned roller press, comprising the following processes:

[0096] A. molten steel smelting

[0097] A1. According to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com