Hard high-torque cross-recessed punch assembly

A high-torque, cross-groove technology, applied in the field of hard high-torque cross-groove punch assemblies, can solve the problems of easy wear, deformation and failure of cross-groove punches, difficulty in ensuring the relevant dimensions of the cross-groove, and large extrusion deformation resistance. , to achieve the effect of convenient processing, simple structure and improved mold life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation, structure, features and functions of the rigid high-torque cross-recessed punch assembly proposed according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

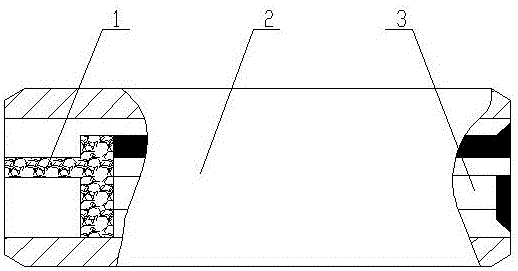

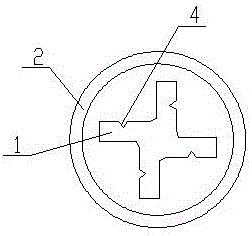

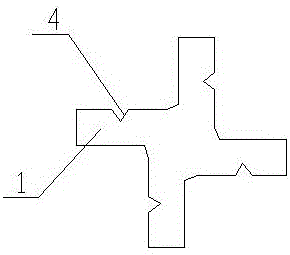

[0020] see Figure 1 to Figure 6 , the hard high-torque cross-recessed punch assembly of the present invention includes a punch 1 and a clamping body 2, wherein: the punch 1 is installed in the groove body 3 inside the clamping body 2, and the punch 1 is a cross-shaped punch Head, the groove body 3 is a cross-shaped groove matched with the punch 1. The punch 1 and the tank body 3 are fitted together by brazing. The punch 1 is made of tungsten-cobalt hard alloy material. The clamping body 2 is made of medium carbon structural steel. Each strip of the punch 1 is provided with grooves 4 .

[0021] When in use, the punch 1 is made of tungsten-cobalt hard alloy material, which has the advantages of wear res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com