Movable type cross-cutting shear waste chain connecting inclined roller way

A cross-cut shearing and movable technology, which is applied to the attachment of shearing machines, shearing machine equipment, shearing devices, etc., can solve the problem of waste or sample 6 not being transported normally, time-consuming safety hazards, waste or sample stuck To avoid problems such as resistance, reduce the downtime of abnormal equipment failures, maintain efficient and convenient maintenance, and directly and quickly disassemble and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

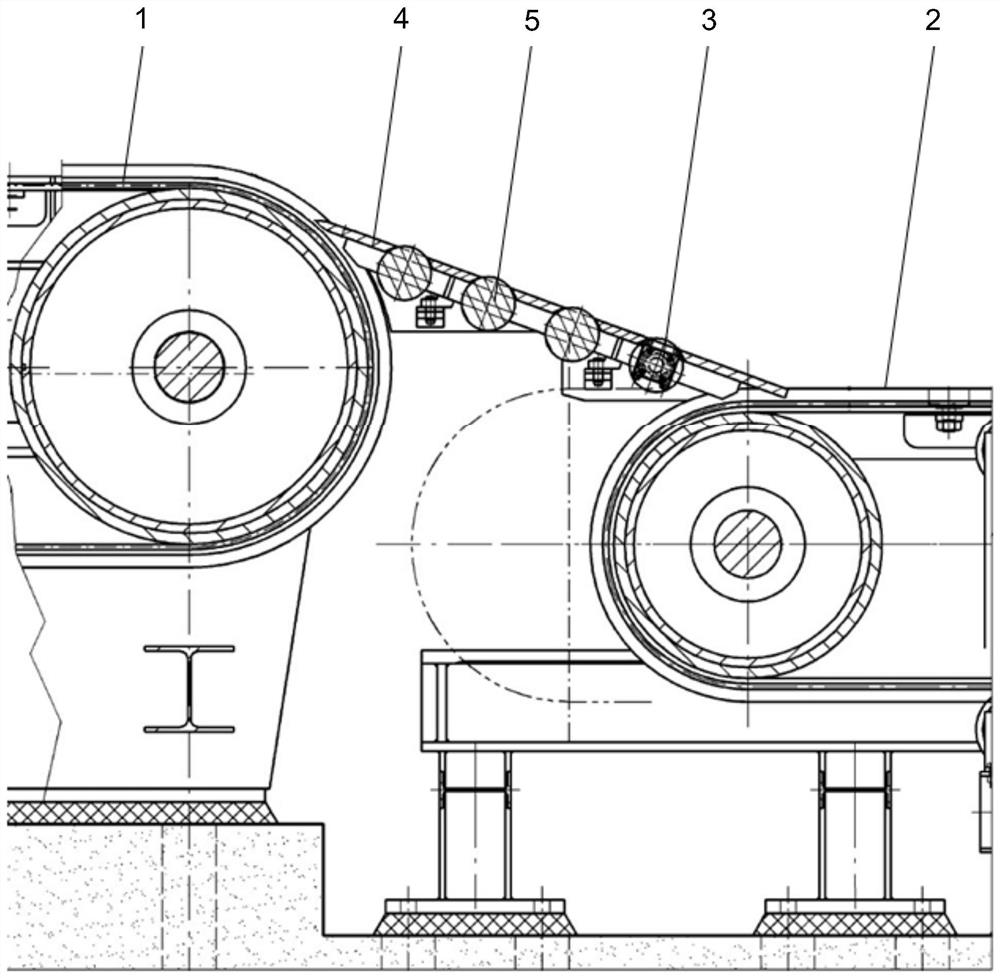

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

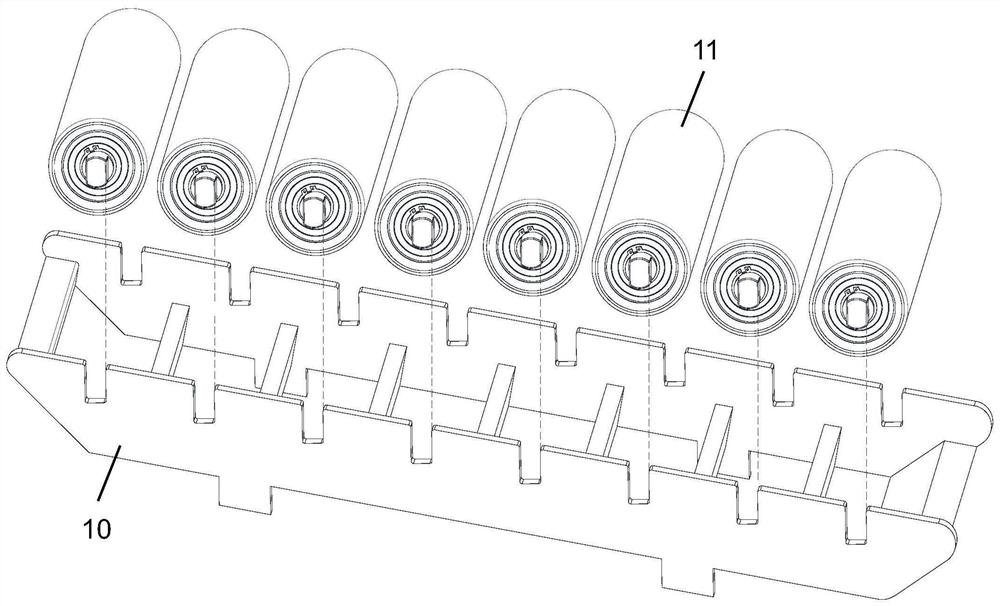

[0027] Please combine image 3 As shown, the inclined roller table for the transfer of a movable cross-cutting waste chain provided by the present invention includes an idler bearing frame 10, and several idler rollers installed in parallel on the idler bearing frame 10 through a detachable structure 11, that is, the two ends of the axle of the idler roller 11 can be directly embedded in the corresponding installation notch 22 on the side plate 19 of the idler bearing frame 10, no bearing seat is required, the cost is lower, and the replacement and maintenance are more convenient.

[0028] Please combine Figure 4 As shown, the idler rollers 11 all include a central stepped shaft 12 , a shaft circlip 13 , deep groove ball bearings 14 with double dust-proof covers, and a hollow idler roller 15 .

[0029] Both ends of the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com