Foldable robot

A robot and folding technology, applied in the field of robotics, can solve problems such as inability to adjust, single function of the robot, and inability to meet production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

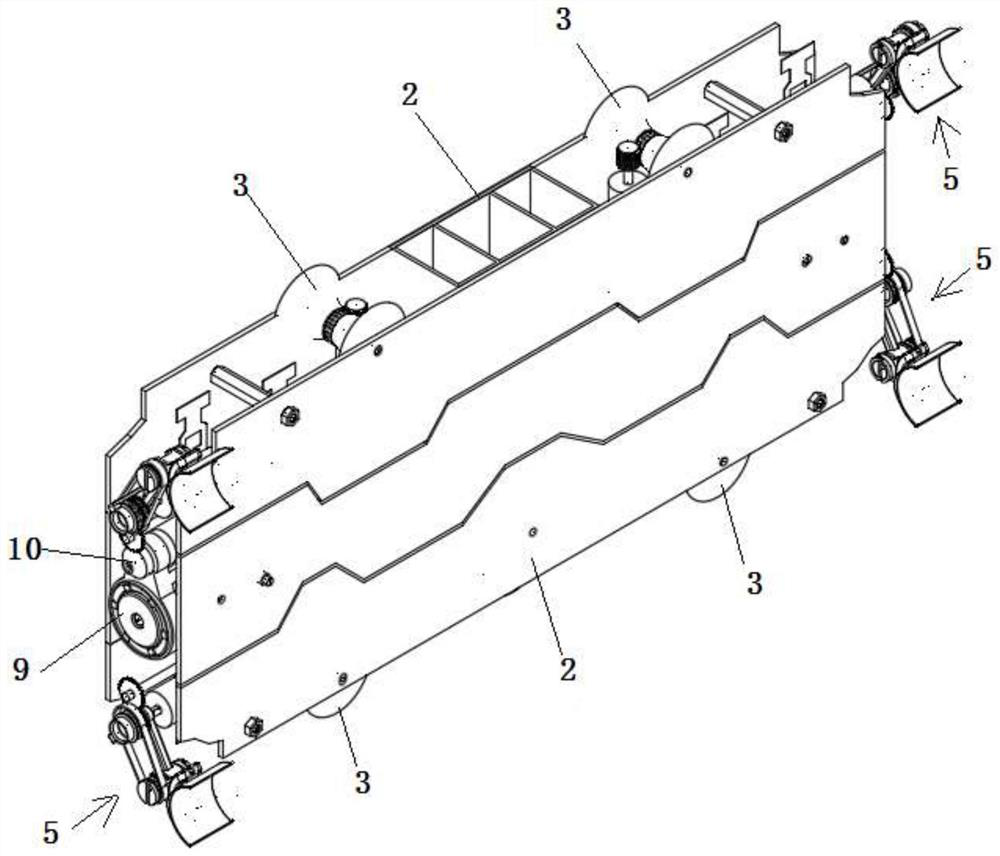

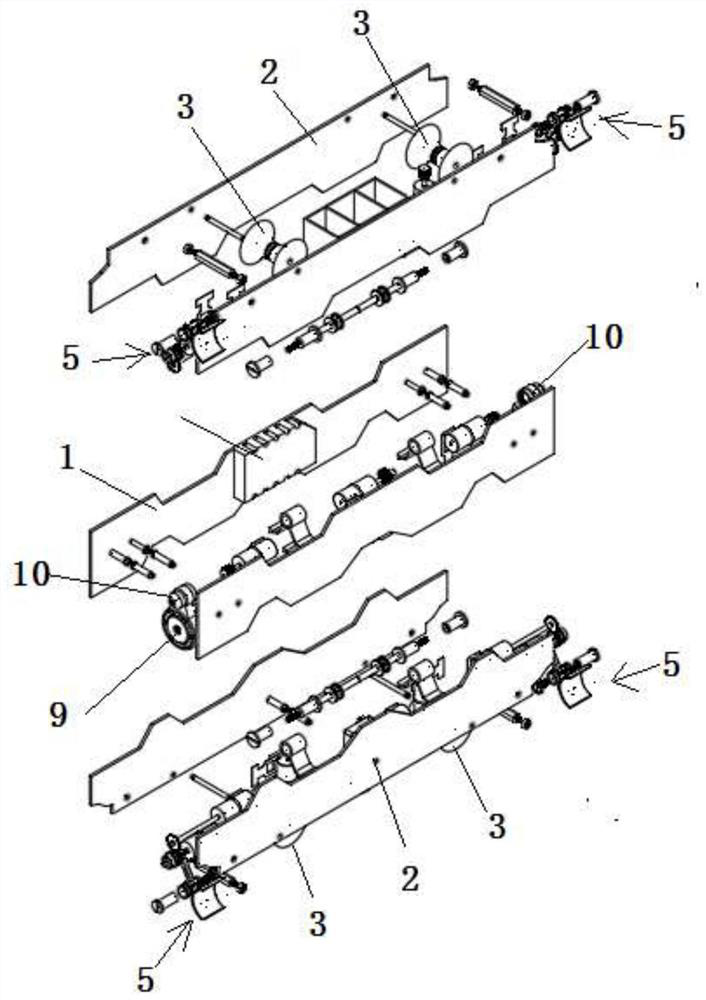

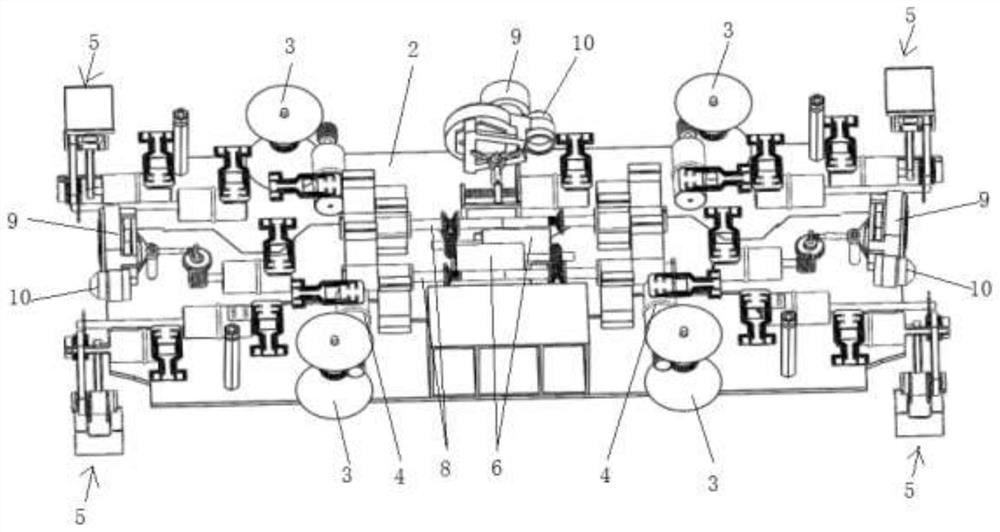

[0037] On the basis of the above structure, in this embodiment, each crawling device includes a housing 2 and at least one running gear, one side of the housing 2 is rotationally connected and positioned with one side of the main body 1; the running gear is installed on the housing The other side of 2 is used to drive the housing 2 to walk. When in use, the two traveling mechanisms can walk on the pipeline, and drive the housing 2 and the main body 1 to walk on the pipeline, so as to realize automatic maintenance of the pipeline, with high maintenance efficiency and low labor intensity.

[0038] Both sides of each casing 2 are open.

[0039] In the two crawling devices, the specific connection method between one side of each shell 2 and one side of the main body 1 can be as follows: the main body 1 includes a shell, and the shell is composed of two fixed plates distributed at intervals, and the two fixed plates are connected by The plates are fixedly connected; on the inner s...

Embodiment 2

[0042] On the basis of Embodiment 1, in this embodiment, each traveling mechanism includes a traveling wheel 3 and a driving member 4, and the traveling wheel 3 is installed on one side of the housing 2 through a rotating shaft, and the two ends of the rotating shaft are respectively It is rotatably connected with both sides of the other side of the housing 2; the driving member 4 is fixedly installed on the other side of the housing 2 by bolts, and is used to drive the traveling wheels 3 to rotate. During use, the driving wheel 3 is driven to rotate by the driver 4, and the walking wheel 3 is attached to the pipeline and walks on the pipeline, thereby realizing that the whole robot walks on the pipeline.

[0043] Above-mentioned each driver 4 all adopts traveling motor, and traveling motor is fixedly installed on the housing 2 by bolt, and its driving end is welded together with an end of rotating shaft, drives traveling wheel 3 to rotate by traveling motor.

Embodiment 3

[0045] On the basis of Embodiment 1, preferably, in this embodiment, there are two running gears, and the two running gears are installed at intervals along the direction from one end of the housing 2 to the other end on the other side of the housing 2 . When in use, the two traveling mechanisms can walk on the pipeline, and drive the casing 2 and the main body 1 to walk on the pipeline, so as to realize automatic maintenance of the pipeline, with high maintenance efficiency and low labor intensity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com