Environment-friendly paper straw and processing technology thereof

A processing technology and environment-friendly technology, which is applied in the field of environment-friendly paper straws and their processing technology, can solve the problems of low hardness of the piercing end of paper straws and easy softening of the water-absorbing end, and achieve the effect of increasing hardness and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in further detail below in conjunction with the accompanying drawings.

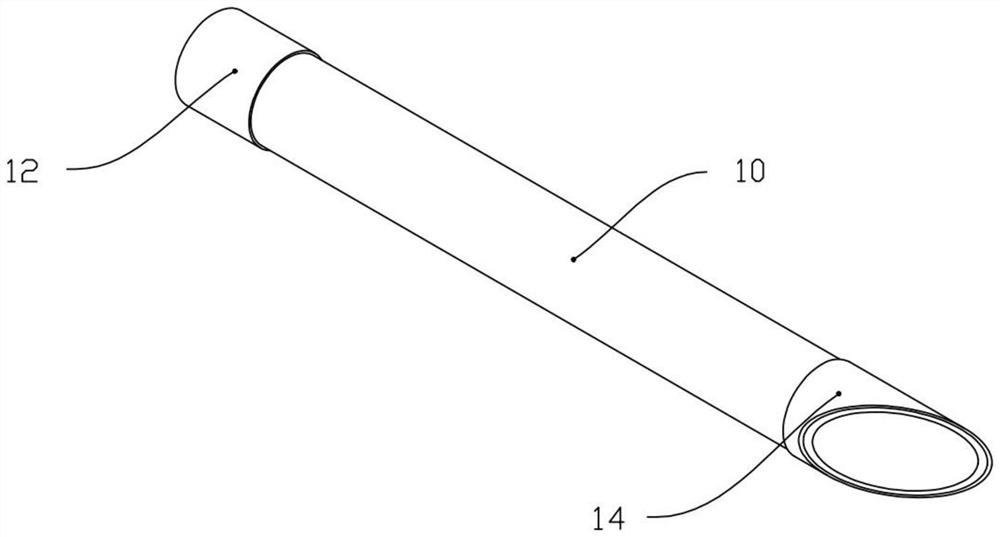

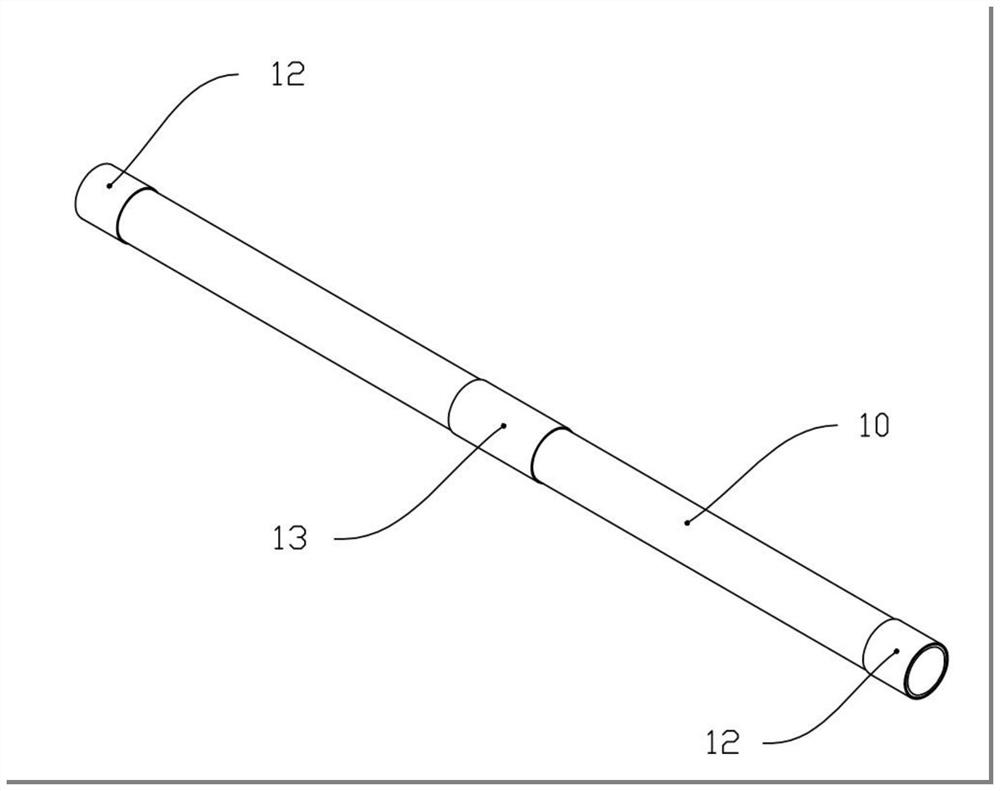

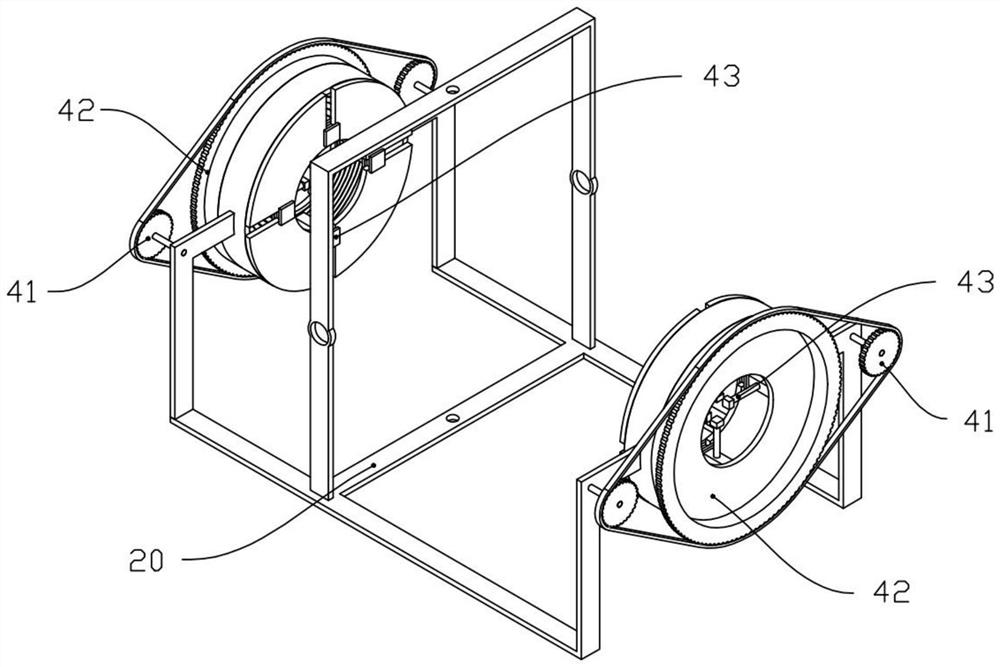

[0070] Combine below Figures 1 to 12Describe this embodiment;

[0071] A kind of environment-friendly paper straw processing technology, this technology comprises the following steps:

[0072] S1: Insert the paper straw 10 into the supporting pipe 30 of the environmental-friendly paper straw processing device, and the feeding mechanism 50 pushes the paper straw 10 to move;

[0073] S2: the material transfer mechanism 60 drives the paper straw 10 to rotate, and the injection molding mechanism 80 injects the cutting tube 13 onto the paper straw 10;

[0074] S3: The cutting mechanism 70 cuts the cutting section tube 13 to form a paper straw to be processed, and cuts the middle part of the paper straw to be processed obliquely to form two environment-friendly paper straws.

[0075] An environment-friendly paper straw processing device, comprising a device bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com