Embossing device and process for producing paper surface gypsum embossed acoustic board

A technology of plaster on paper and production technology, which is applied in the direction of sound insulation, decorative art, building components, etc. It can solve problems such as difficulties, embossing pressure cannot be adjusted, and cumbersome operation, and achieve the effects of convenient operation, saving manpower and material resources, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

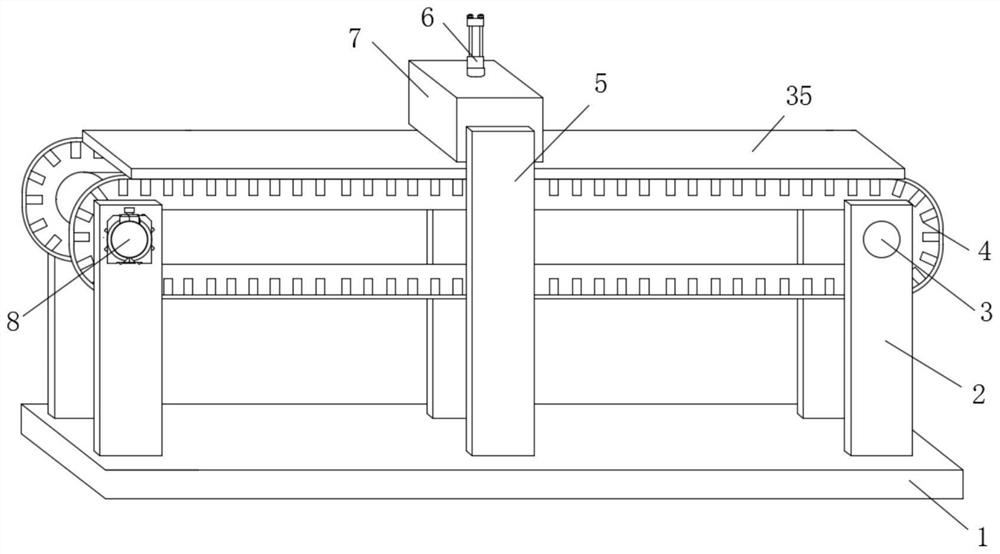

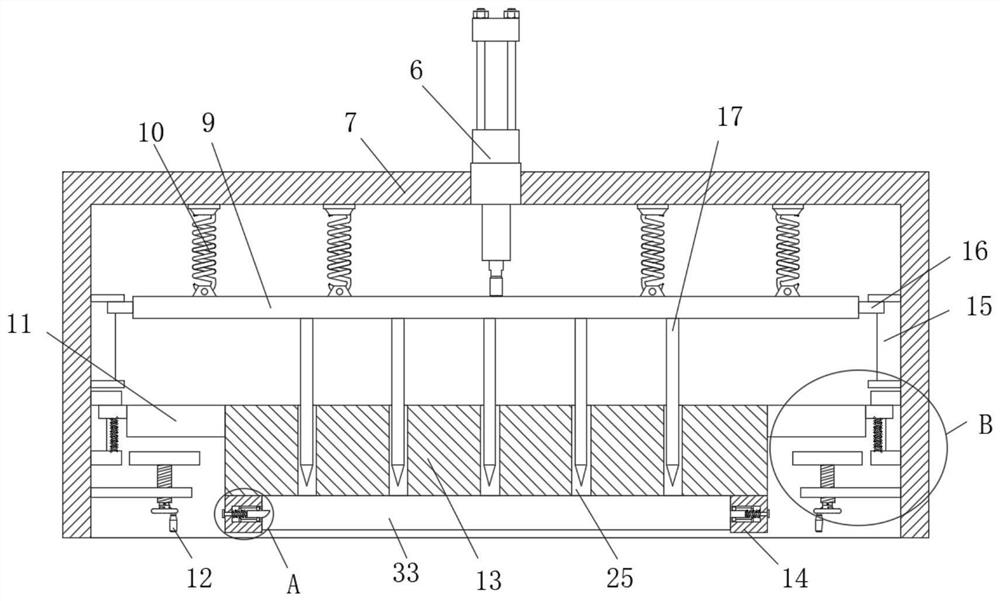

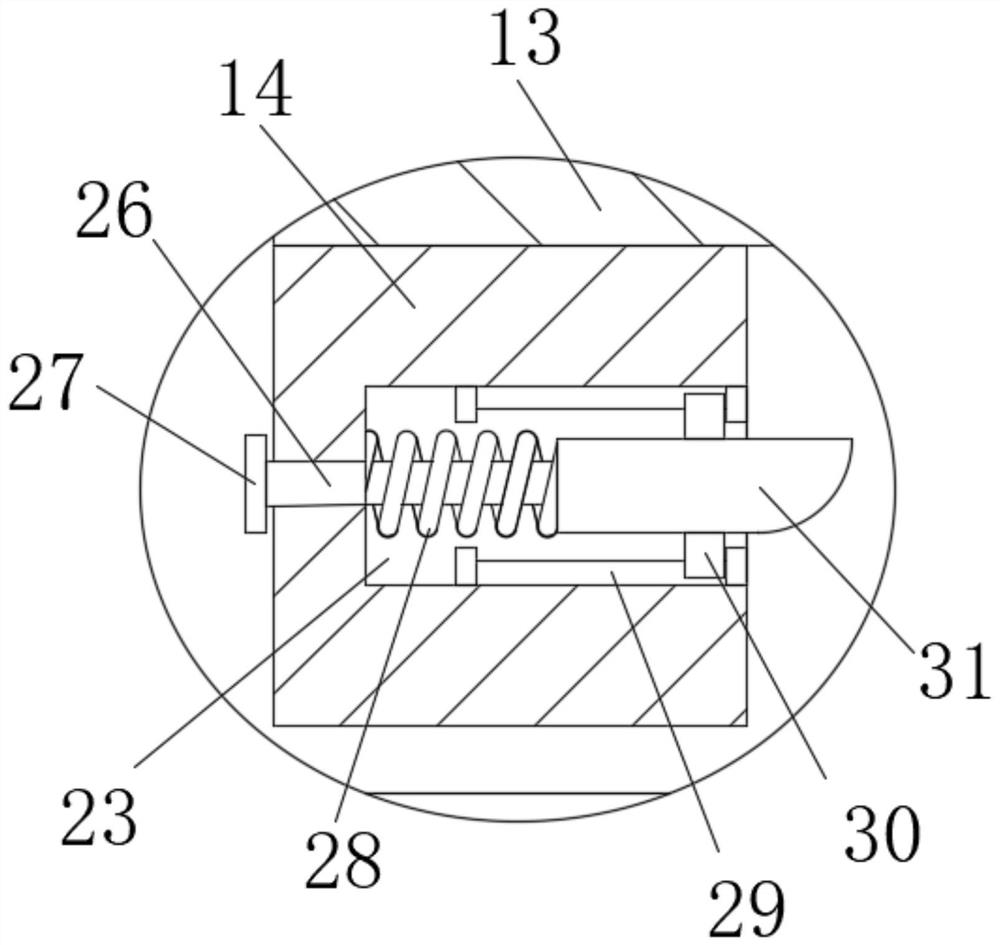

[0029] refer to Figure 1-8 , a kind of embossing equipment for the production of plaster embossed sound-absorbing panels, comprising a mounting plate 1 and a body 35 of plaster embossed sound-absorbing panels, the top of the mounting plate 1 is fixedly connected with two symmetrically arranged second fixing plates 5 and There are four first fixed plates 2 that are symmetrical in pairs, and a transmission assembly for conveying the main body 35 of the plaster embossed sound-absorbing panel 35 is arranged between the four first fixed plates 2 , and the sides of the two second fixed plates 5 are close to each other The same rectangular box 7 is fixedly connected, the plaster embossed sound-absorbing panel body 35 is located above the transmission component, the plaster embossed sound-absorbing panel body 35 is located directly below the rectangular box 7, and the inner walls of both sides of the rectangular box 7 are slidingly connected There is the same horizontal plate 9, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com