Vision-based quantitative liquid filling system and liquid filling method thereof

A liquid filling and visual technology, applied in the field of vision-based quantitative liquid filling system, to achieve the effect of increasing the qualified rate and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

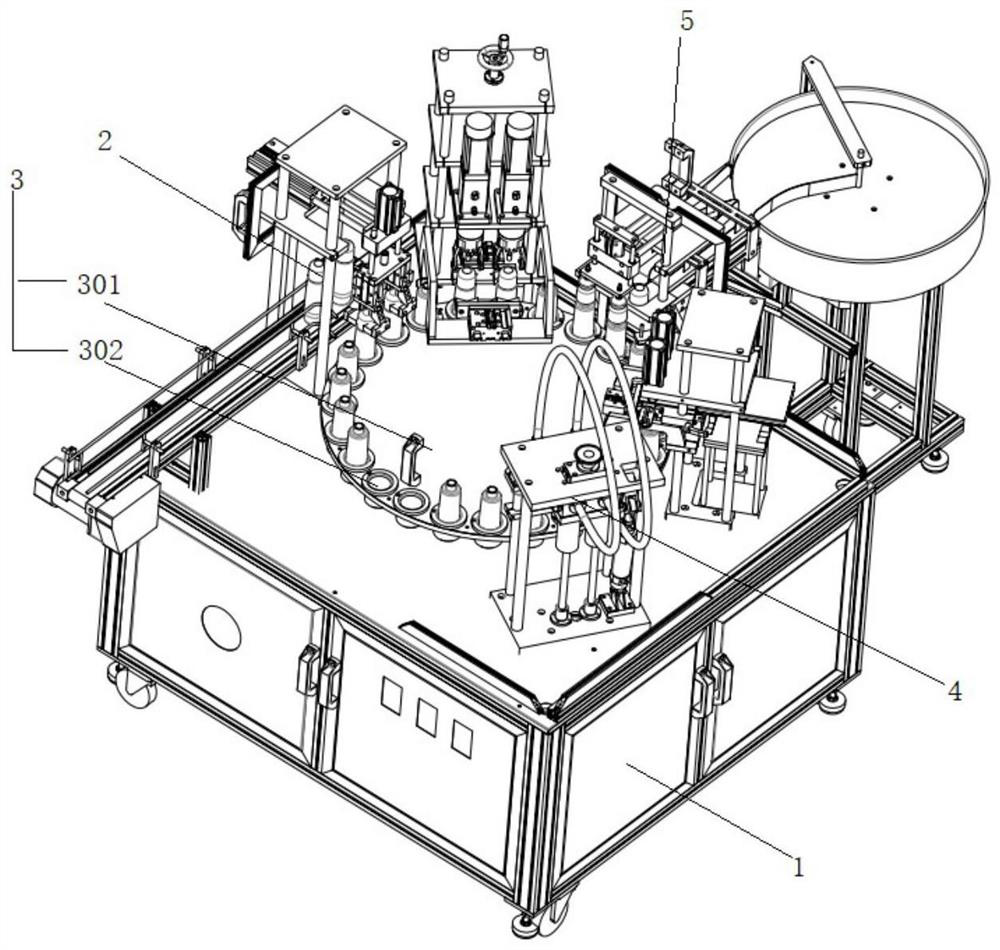

[0052] This embodiment discloses a vision-based quantitative irrigation system, such as figure 1The shown body includes a fuselage 1, on which a transport unit 3 is arranged, and clockwise around the transport unit 3, it also includes: a loading unit 2, a liquid filling unit 4 and a discharge unit 5. Wherein, the feeding unit 2 is used to transfer the bottle body to be filled with liquid from the transportation line to the transportation unit 3, and the bottle body to be filled with liquid is transferred to the liquid filling unit 4 by the rotation of the transportation unit 3. Unit 4 fills the bottle to be filled with liquid. When the predetermined filling standard is reached, the transport unit 3 continues to rotate clockwise to transport the next liquid filling unit 4 to be filled with the bottle. The liquid filling bottle is transferred to the unloading unit 5, and the next process is carried out through the unloading unit 5, such as screwing the cap.

[0053] If existing...

Embodiment 2

[0064] In order to ensure the qualified rate of the product, that is, the liquid in each bottle conforms to the predetermined standard value, and the applicant cannot deviate too much. If the liquid is too little, it obviously does not meet the quality inspection standard. If the liquid is too high, it not only fails to meet the quality inspection standard, but also increases the difficulty of the later cover.

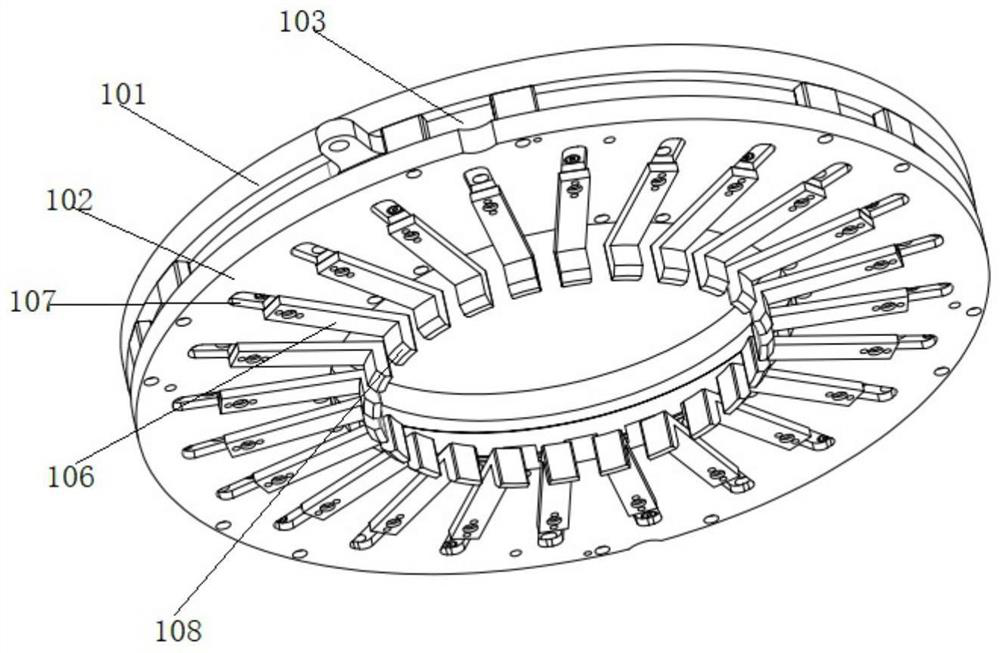

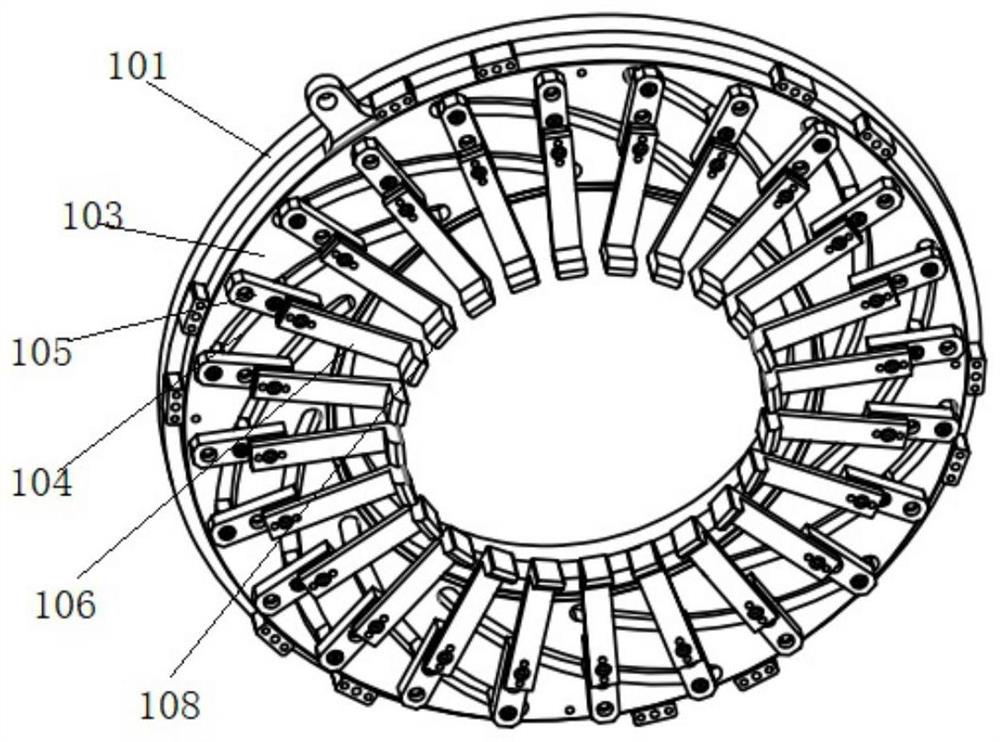

[0065] Based on Embodiment 1, the following improvements are made to the transport unit: a vertical light source is provided at the bottom of each placement cavity. At the same time, in the liquid filling unit, each liquid injection gun is equipped with a matching camera, and the camera is set to collect images of the current bottle body and obtain the liquid level value inside the bottle body. Setting the vertical light source is convenient for the camera to collect images, and the liquid level detection of different liquids, especially the detection of transparent li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com