System and method for improving gas flow control lag of fuel cell

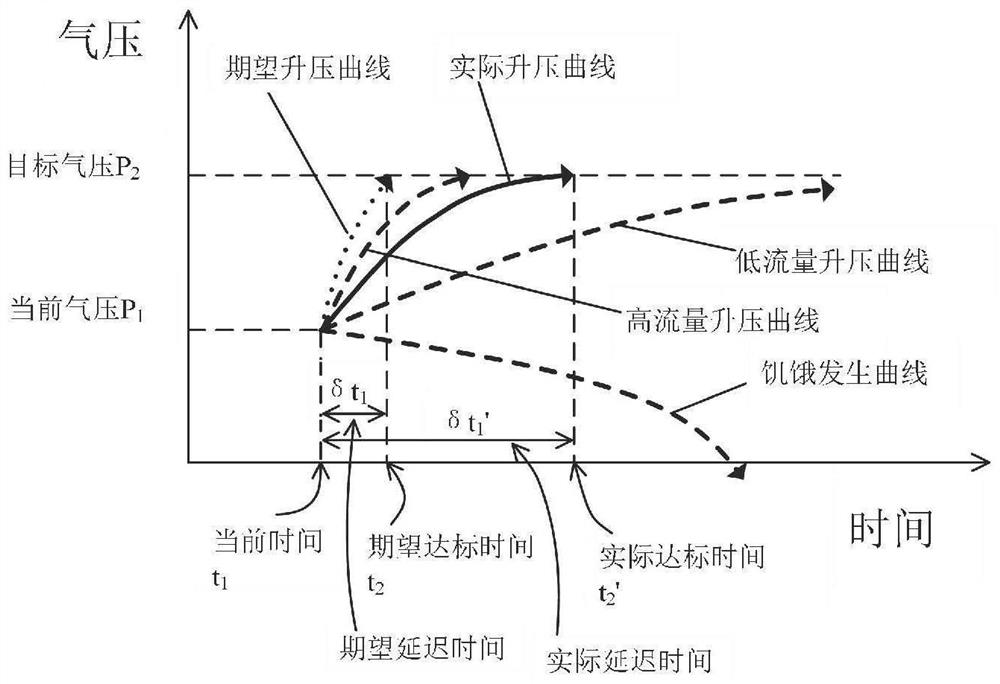

A gas flow, fuel cell technology, applied in fuel cells, electrical components, circuits, etc., can solve problems such as unfavorable control, increase insulation volume, cylinder power consumption, etc., to improve accuracy and response speed, and reduce the impact of dead volume , reducing the effect of gas hunger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

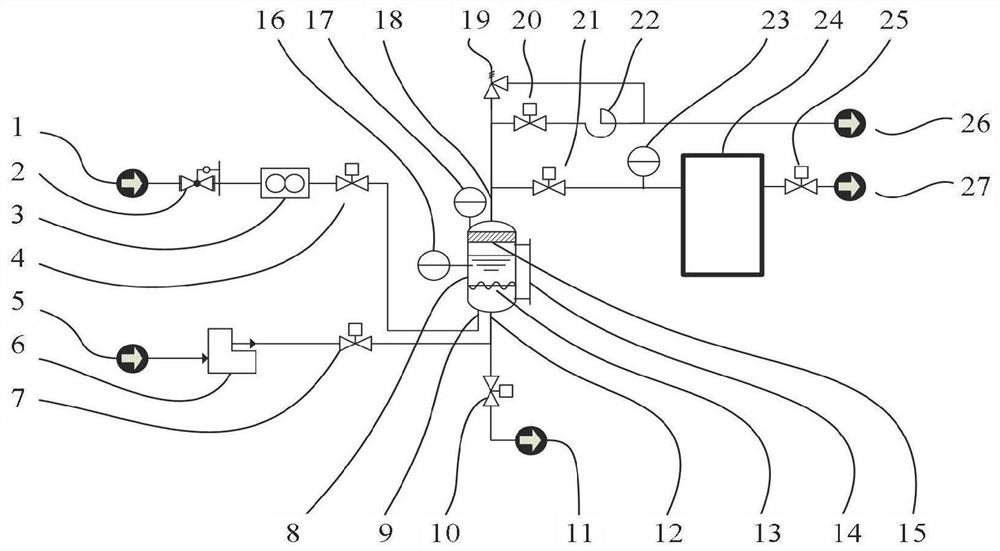

[0051] A system for improving fuel cell gas flow control hysteresis, consisting of a gas source 1, a water supply source 5, a bubbling humidifier 8, and related control components and pipelines; the gas source 1 is decompressed by a pressure reducer 2, and the flow rate is controlled The device 3 controls the flow rate and the air supply valve 4, and sends it to the bubbling humidifier 8 for humidification; the water replenishment water source 5 is controlled by the water replenishing metering pump 6, and when necessary, the bubbling humidifier 8 is replenished with water, and the pressure of the water replenishing metering pump 6 is greater than that of the drum The highest pressure of the bubble humidifier 8, open the replenishment valve 7, and replenish water into the bubble humidifier 8; the bubble humidifier 8 is connected with a gas inlet 9, an air supply valve 4, a drain valve 10, a safety valve 19, an exhaust valve Valve 20, battery air supply valve 21, with a bubbling ...

Embodiment 2

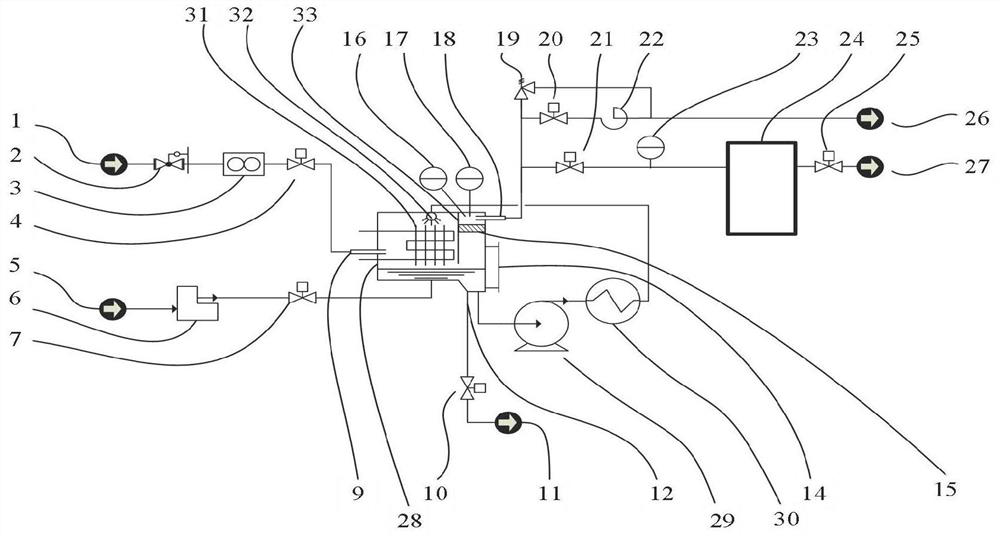

[0055] The difference from Example 1 is that the spray humidification method is adopted.

[0056] The inside of the spray humidifier 28 is provided with a spray inner heater 31, which heats the gas and the sprayed water, so that the gas can be humidified by water vapor, and the gas humidification reaches the humidification temperature. The heater can also be set as an external circulation heater. The partition 33 divides the spraying and defoaming into two spaces. These two spaces are front and rear or down and up according to the airflow direction. The airflow first passes through the spraying space and then through the defoaming space. The partition 33 is higher than the water surface. The gas reaches the demisting space from the spraying space between the partition 33 and the water surface. The spray pump 29 conveys water for circulation and spraying. The circulating water flows through the spray external heater 30, sprays fine water droplets from the spray nozzle 32 and e...

Embodiment 3

[0058] The system tests the battery, including cold and hot starts. see Figure 4 , for the above system, the present invention improves fuel cell gas flow control hysteresis method, as follows:

[0059] Step S001: Judging whether to measure the system dead volume parameter; if the judgment result is "yes", proceed to step S010; if the judgment result is "no", proceed to step S002;

[0060] (1) When measuring the system dead volume parameter, carry out the following steps:

[0061] Step S010: Do not heat, close the air supply valve 4 without supplying air, close the exhaust valve 20, open the drain valve 10, discharge water from the drain port 11, and control the flow controller 3 to supply air to the humidifier according to the measured value of the pressure sensor 17 , maintain the uniform flow rate of gas supply, keep the pressure at 0.001 ~ 0.01MPag, when the detected gas pressure drops suddenly, close the drain valve 10, close the gas supply valve 4 to stop the gas supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com