Bionic flexible paddy field inter-row driving type weeding unit

A driving and flexible technology, applied in the field of agricultural machinery, can solve the problems of increased operation traction, low weeding efficiency, poor weeding quality, etc., and achieves the effects of high operating efficiency, good weeding effect and low power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

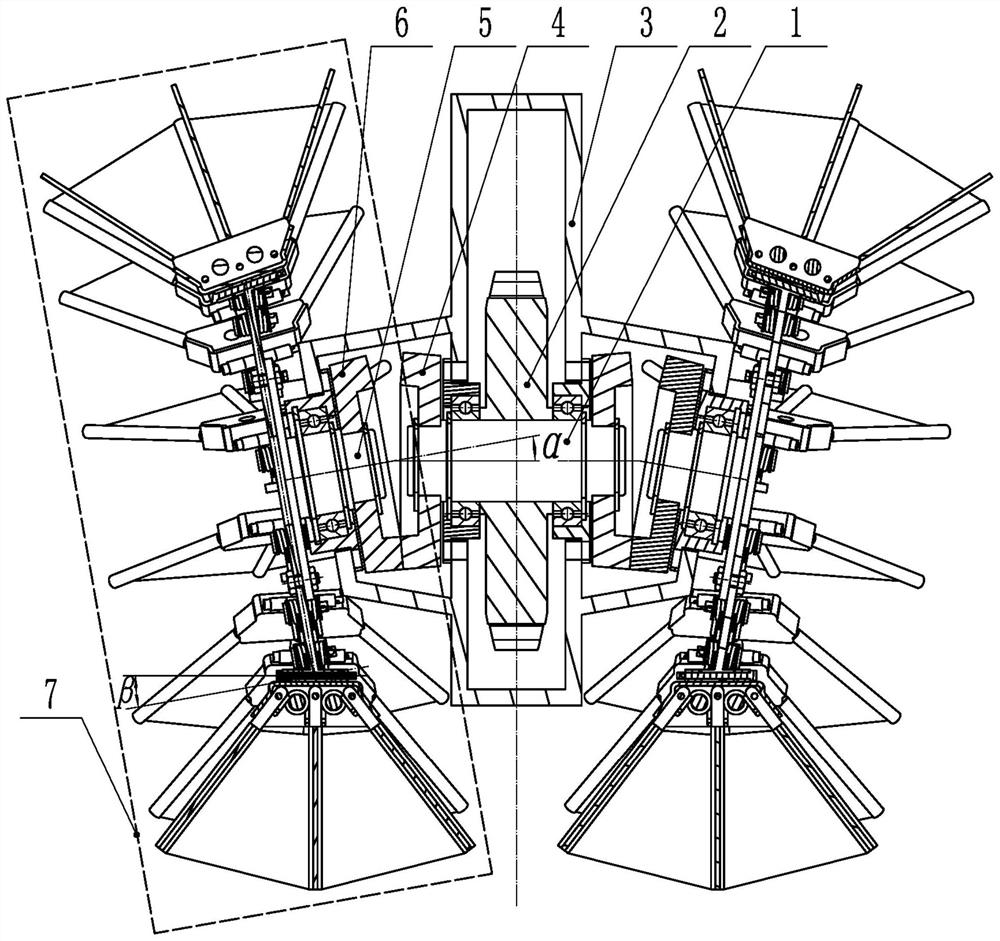

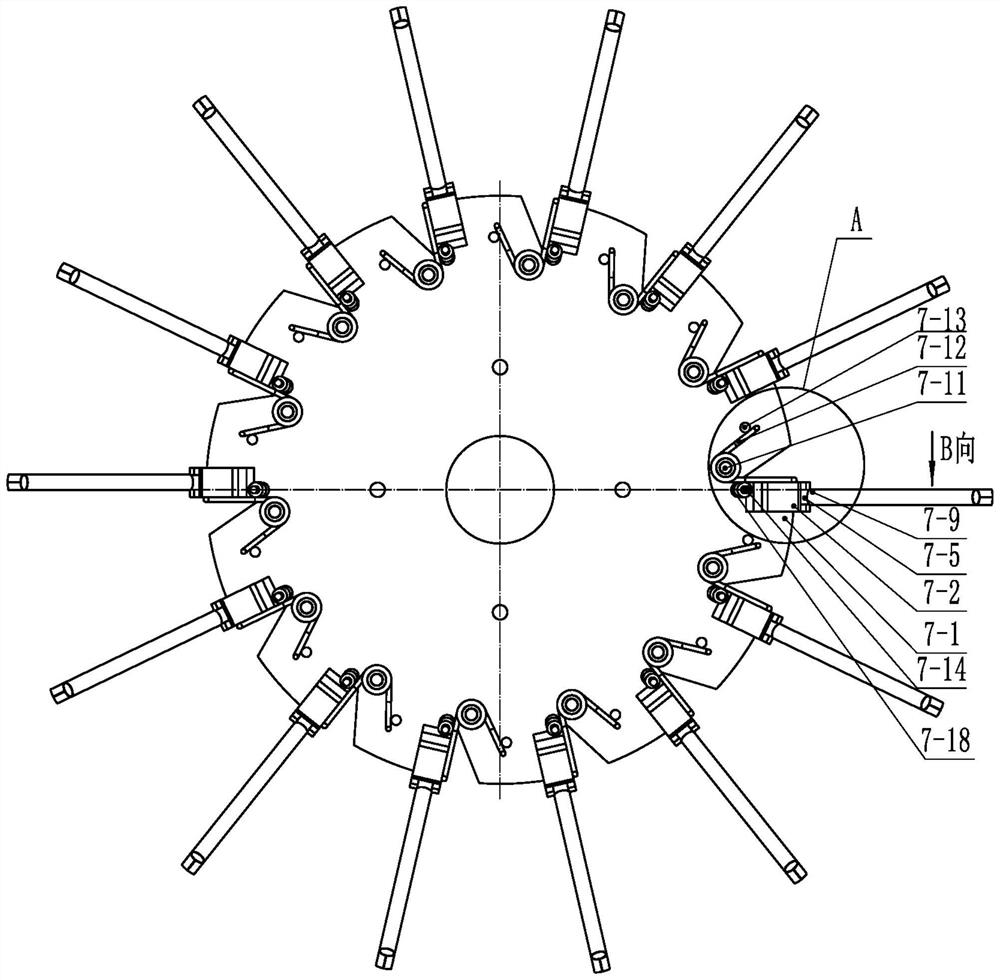

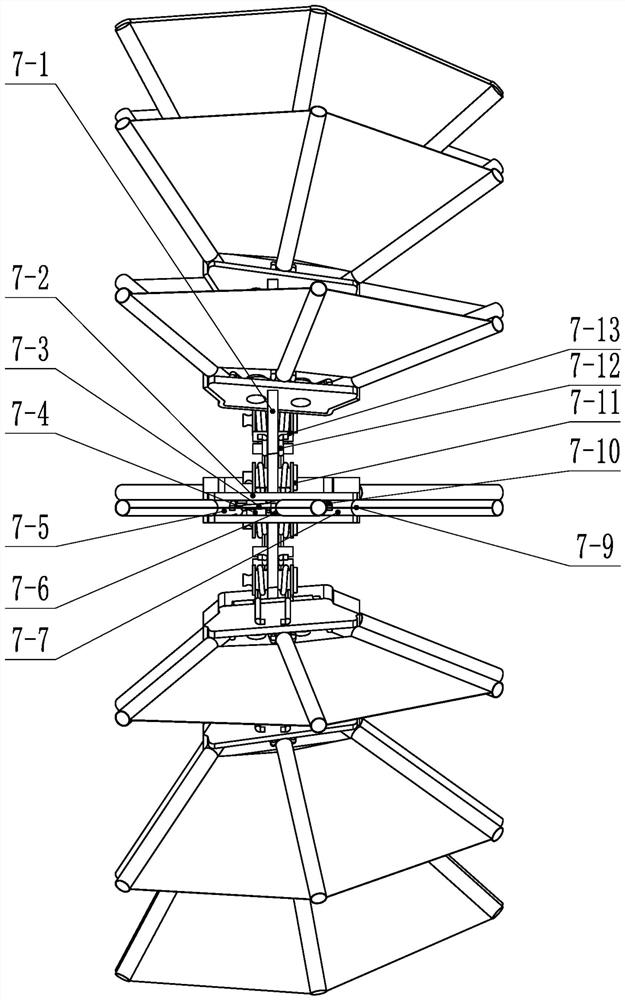

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A bionic flexible paddy field drive-type weeding unit, in which a driving main shaft 1 is rotatably installed on the middle part of the inner side of the drive box housing 3, and a driving sprocket 2 is fixed on the middle part of the driving main shaft 1. On the left and right ends of the driving main shaft 1, mutually symmetrical driving bevel gears 4 are respectively fixed, and on the left and right sides of the driving box housing 3, they are respectively installed symmetrically and rotatably at the outer parts of the two ends of the driving main shaft 1. Drive semi-shaft 5, the axis line of said driving semi-axis 5 and the axis line of drive main shaft 1 are provided with a down-tilt angle α, and the driven bevel gear 6 is fixed on the inner end of drive semi-axis 5, so The driven bevel gear 6 meshes with the driving bevel gear 4, and the bionic fle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com