Integrated double-color needle protective cap

A needle protection cap and integrated technology, which is applied in the field of integrated two-color needle protection cap, can solve the problems of user safety hazards, low qualification rate and high production cost, and achieve the effects of safe use, long service life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

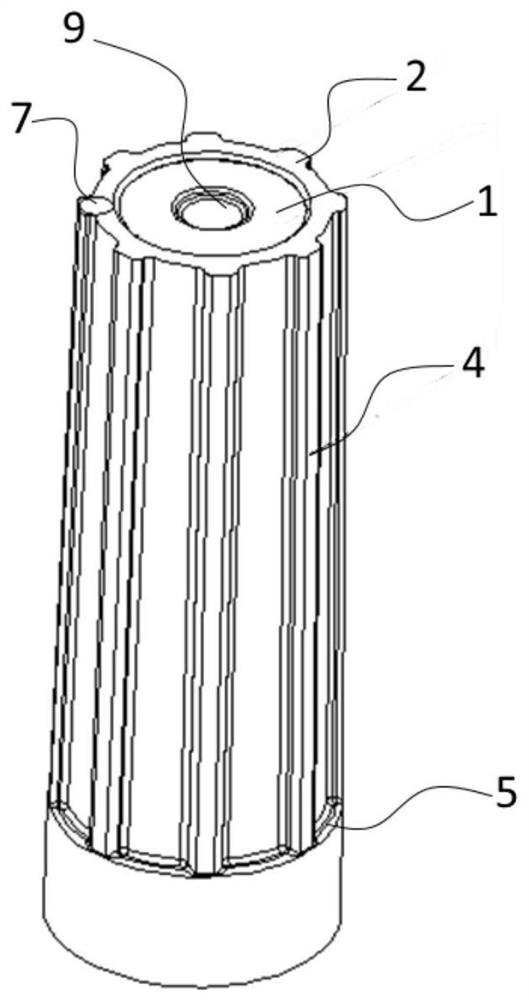

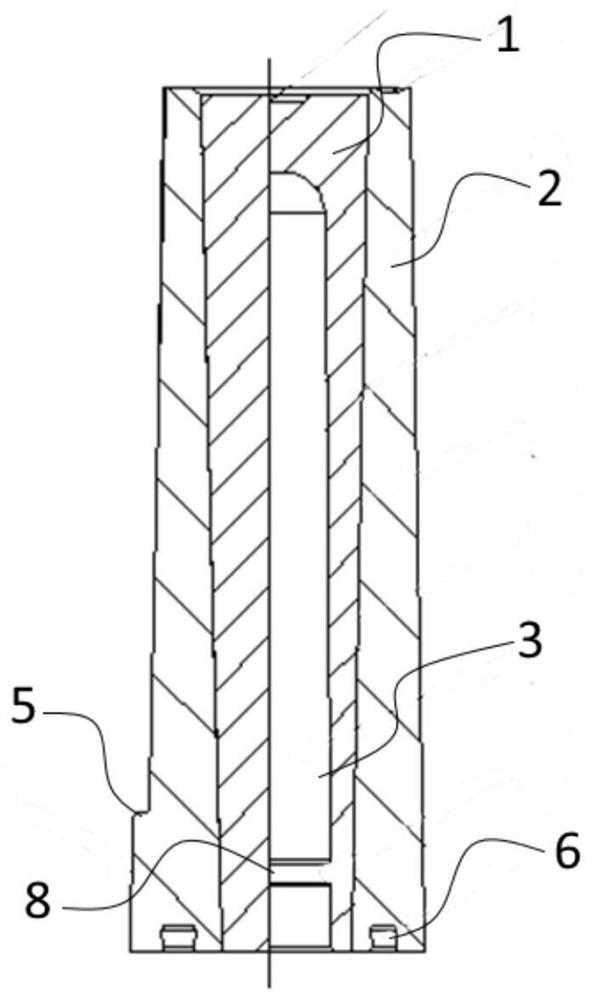

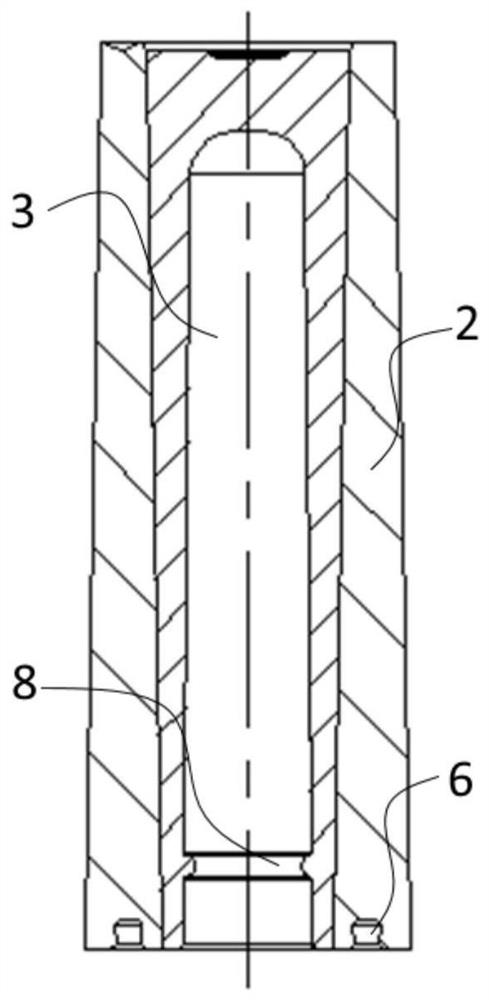

[0031] Such as Figure 1 to Figure 5 As shown, the one-piece two-color needle protective cap includes: an inner protective cap 1 and an outer protective cap 2; the material of the inner protective cap 1 is thermoplastic elastomer, and the material of the outer protective cap 2 is PP or PE.

[0032] The outer protective cap 2 is set outside the inner protective cap 1, and the outer protective cap 2 and the inner protective cap are joined together by injection molding to form an integrated structure. When the integrated two-color needle protective cap is pulled out from the needle seat, PP / PE will not appear The case of separation from the thermoplastic elastomer; the occlusal surface of the outer surface of the inner protective cap 1 and the inner surface of the outer protective cap 2 is vertical or has a taper, which can be implemented in this embodiment;

[0033] The center of the lower end surface of the inner protective cap 1 is provided with an inner cavity channel 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com