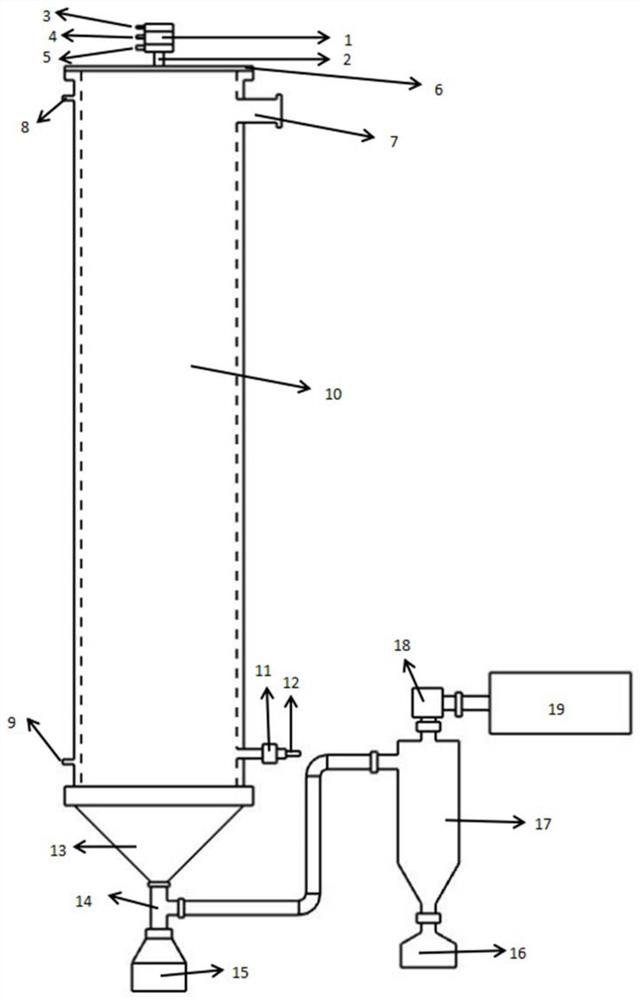

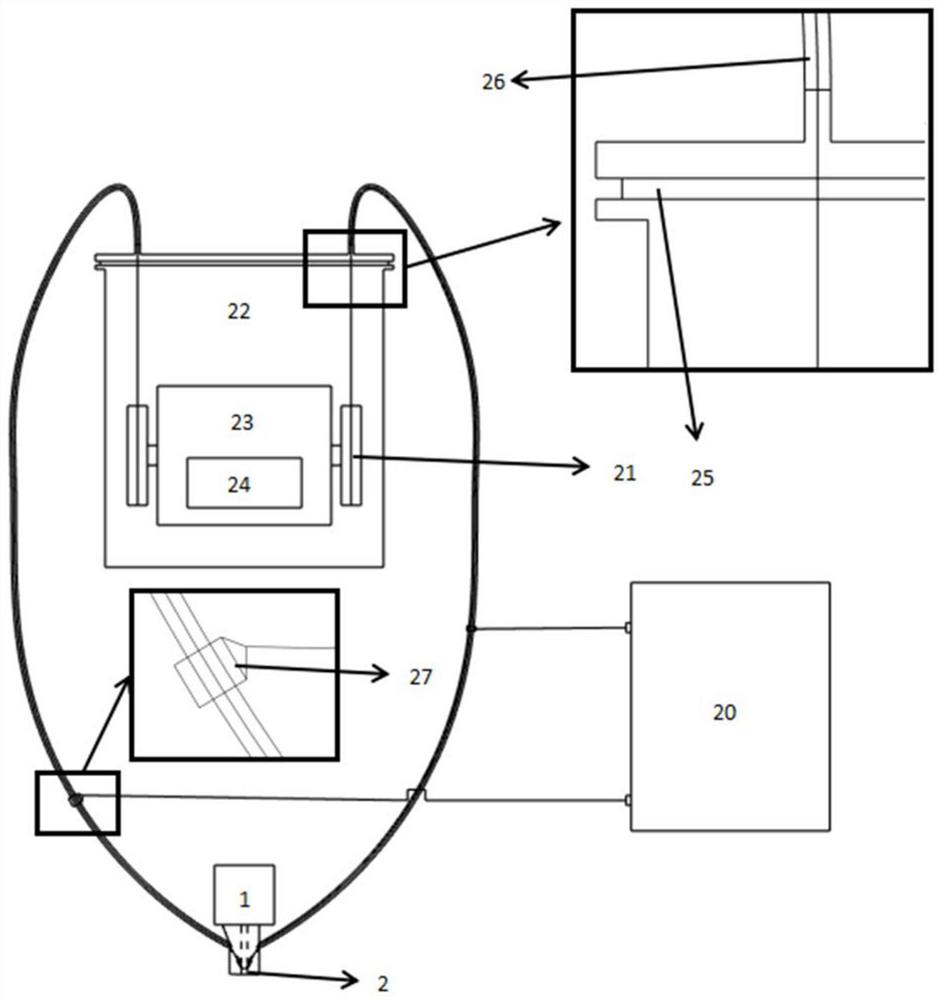

Method and equipment for preparing spherical metal powder through arc-assisted plasma atomization

A metal powder and plasma technology, used in powder metallurgy and advanced manufacturing, ion atomization to prepare spherical metal powder, can solve the problems of insufficient wire melting, low production efficiency of fine powder, high power consumption, and achieve simple and compact equipment structure. , good surface appearance, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

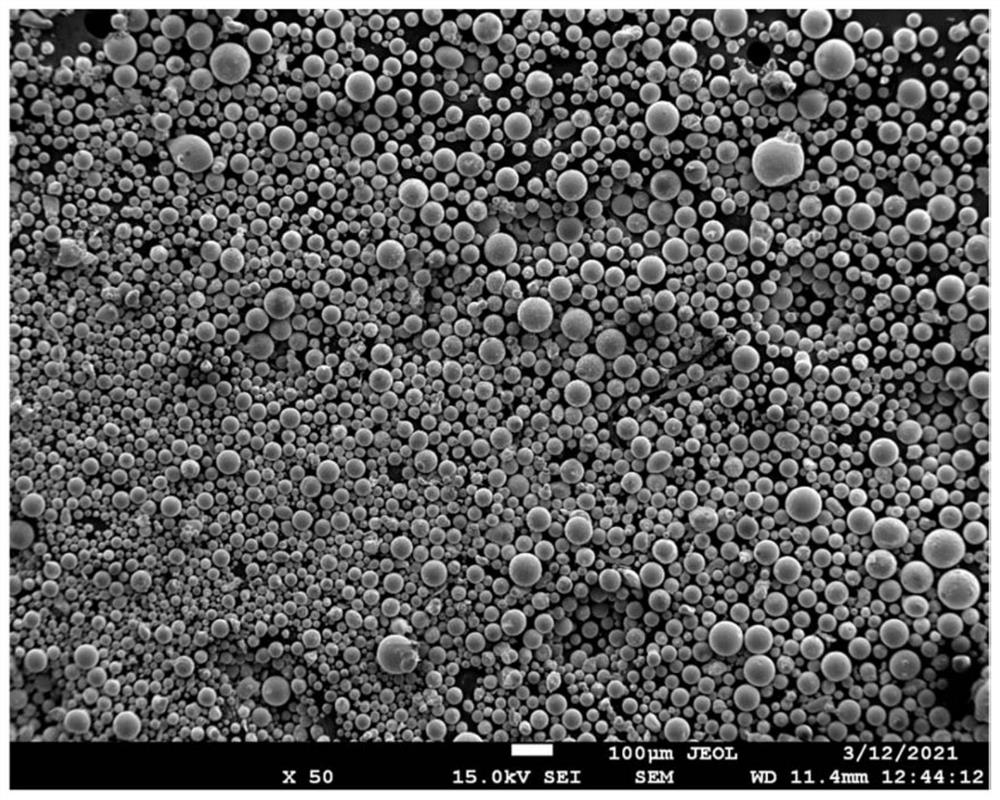

example 1

[0040] (1) Material selection:

[0041] The iron-based wire material with a diameter of 1.6mm is selected, and the wire material composition is: C (0.05%), Cr (11.9%), Ni (5.6%), Mn (1%), Mo (0.2%), Si (0.5%) ), Fe (80.75%). Plasma gas adopts Ar+H 2 mixed gas.

[0042] (2) Operation process:

[0043] ① Install the wire to be atomized on the wire feeder and check the tightness, set the wire feeding speed to 100mm / s; ② Turn on the water cooling system, including the water cooling of the plasma generator and the water cooling of the vacuum atomization chamber;

[0044] ③Evacuate the vacuum atomization chamber, and after the air pressure is evacuated to -0.1MPa by a vacuum pump, open the valve of the gas cylinder to introduce high-purity argon gas (99.99%) to make the air pressure reach 0.1MPa, and wait until the inert gas and the remaining gas in the chamber are completely mixed After that, evacuate to -0.1MPa again, and repeat the above content 3 times;

[0045] ④ Adjust th...

example 2

[0052] (1) Material selection:

[0053] The iron-based wire material with a diameter of 1.6mm is selected, and the wire material composition is: C (0.05%), Cr (11.9%), Ni (5.6%), Mn (1%), Mo (0.2%), Si (0.5%) ), Fe (80.75%). Plasma gas adopts Ar+H 2 mixed gas.

[0054] (2) Operation process:

[0055] ① Install the wire to be atomized on the wire feeder and check the tightness, set the wire feeding speed to 100mm / s; ② Turn on the water cooling system, including the water cooling of the plasma generator and the water cooling of the vacuum atomization chamber;

[0056] ③Evacuate the vacuum atomization chamber, and after the air pressure is evacuated to -0.1MPa by a vacuum pump, open the valve of the gas cylinder to introduce high-purity argon gas (99.99%) to make the air pressure reach 0.1MPa, and wait until the inert gas and the remaining gas in the chamber are completely mixed After that, evacuate to -0.1MPa again, and repeat the above content 3 times;

[0057] ④ Adjust th...

example 3

[0064] (1) Material selection:

[0065] Select iron-based wire with a diameter of 1.2mm, and the wire composition is: C (0.01%), Cr (16.7%), Ni (13.3%), Mn (1%), Mo (0.2%), Si (0.5%) ), Fe (68.29%). Plasma gas adopts Ar+H 2 mixed gas.

[0066] (2) Operation process:

[0067] ① Install the wire to be atomized on the wire feeder and check the tightness, set the wire feeding speed to 70mm / s; ② Turn on the water cooling system, including the water cooling of the plasma generator and the water cooling of the vacuum atomization chamber;

[0068] ③Evacuate the vacuum atomization chamber, and after vacuuming the vacuum pump to -0.1MPa, open the valve of the gas cylinder to introduce high-purity argon (99.99%) to make the pressure reach 0.1MPa, and wait until the inert gas and the remaining gas in the chamber are completely mixed After that, evacuate to -0.1MPa again, and repeat the above content 3 times;

[0069] ④ Adjust the current of the DC constant current plasma generator po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com