Bamboo chip bending machine for manufacturing bamboo rings and manufacturing method

A technology of bending machine and bamboo chips, which is applied in the direction of wood bending, manufacturing tools, mechanical equipment, etc., can solve the problems of low efficiency, increased workload of workers, cumbersome modification, etc., to prevent warping and insufficient gluing, and reduce the work of workers Burden, the effect of improving convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

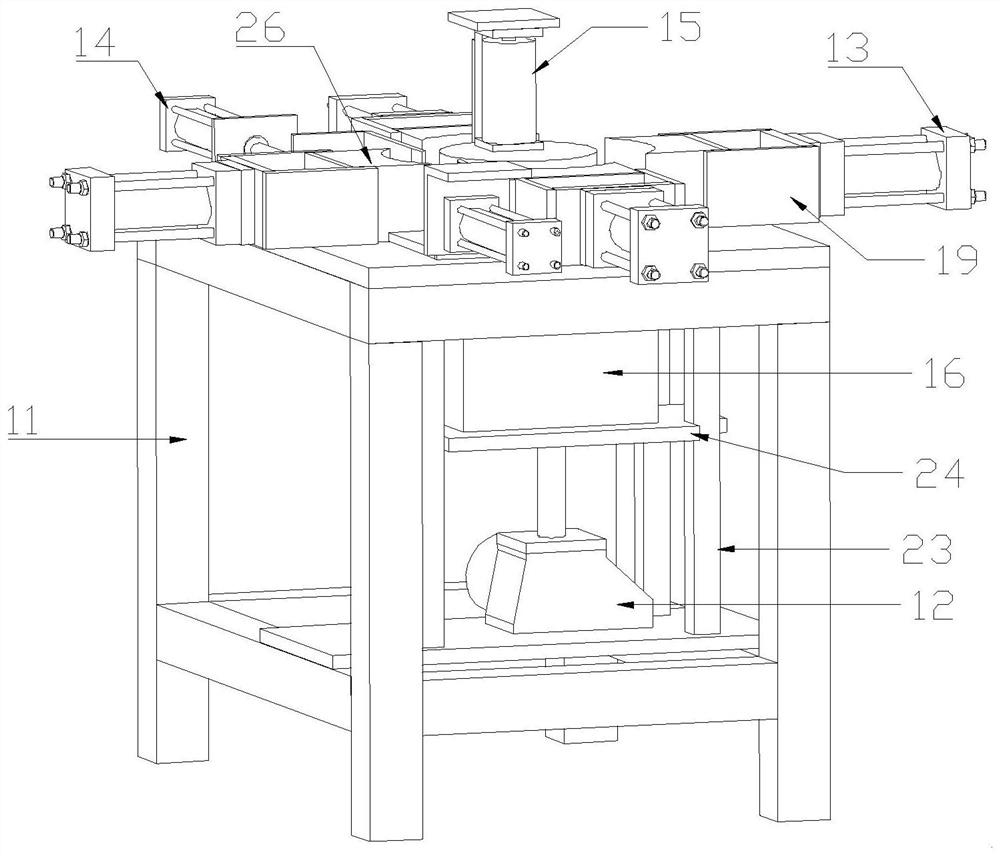

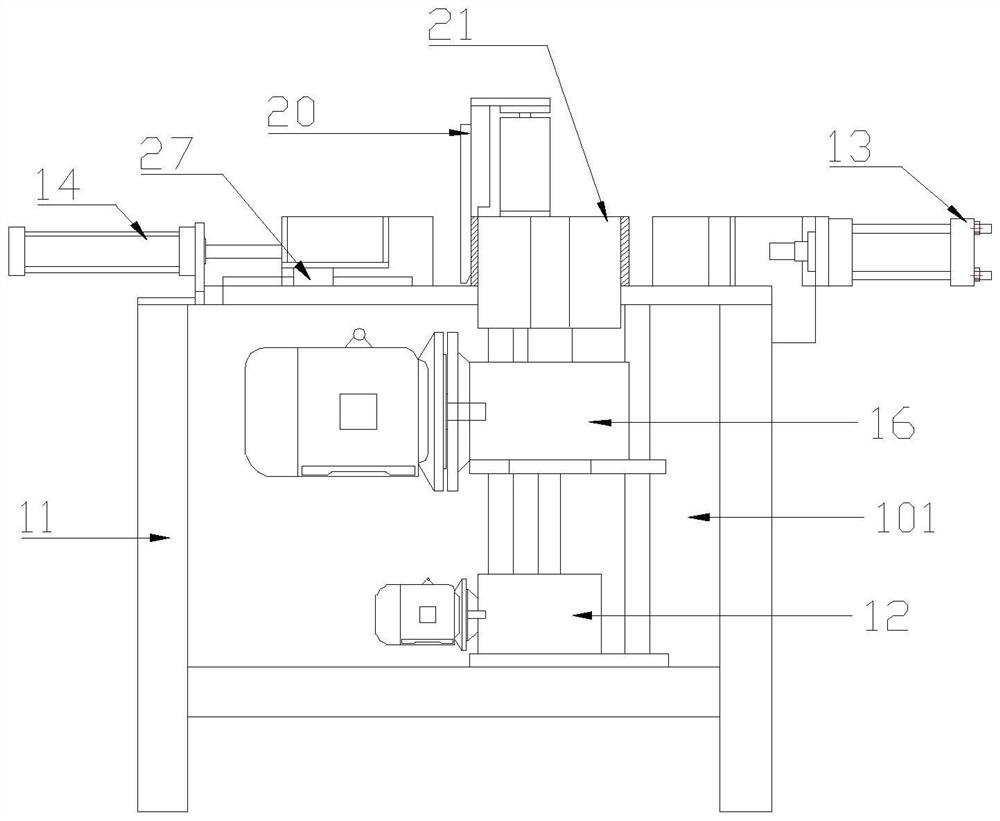

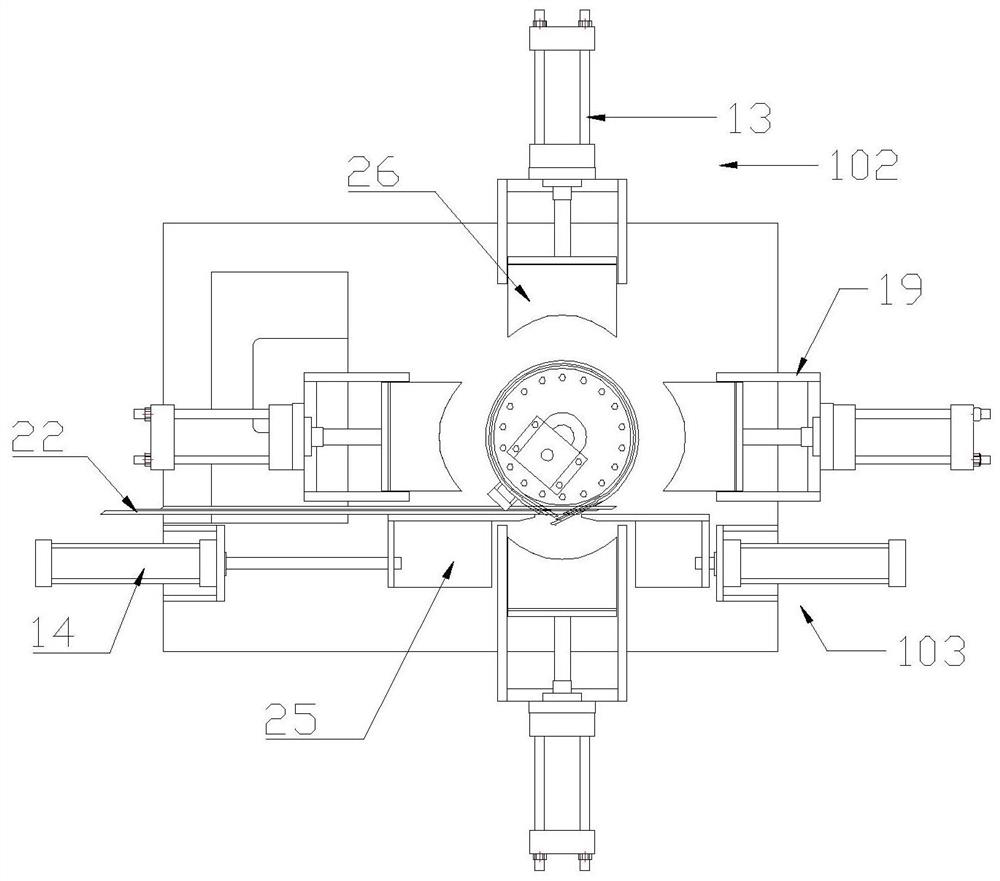

[0028] see Figure 1-4 A bamboo sheet bending machine for preparing bamboo rings and a preparation method thereof, it includes a frame 11, a workbench 21, a feeding guide main part 103 and a compaction main part 102 for compacting bamboo chips 22, the inside of the workbench 21 At least one heating rod is provided, and the heating rod is connected to an external power supply for power supply. While compacting and bending, the bamboo slice 22 is heated to improve the bending effect. It is also possible to directly put the processed bamboo slice 22 into the bending machine without a heating rod. Bending, the feeding guide main part 103 and the compacting main part 102 are installed on the frame 11, and the feeding guide main part 103 includes a feeding limiting mechanism and an edge warping limiting mechanism. The compacting main part 102 includes an edge compacting mechanism and a side compacting mechanism. The edge compacting mechanism and the side compacting mechanism are di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com