Hot pressing technology for manufacturing double-layer kraft paper leakage-proof garbage bag without glue

A hot pressing technology, kraft paper technology, applied in the direction of coating, can solve the problem of paper garbage bags not being leak-proof and not environmentally friendly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

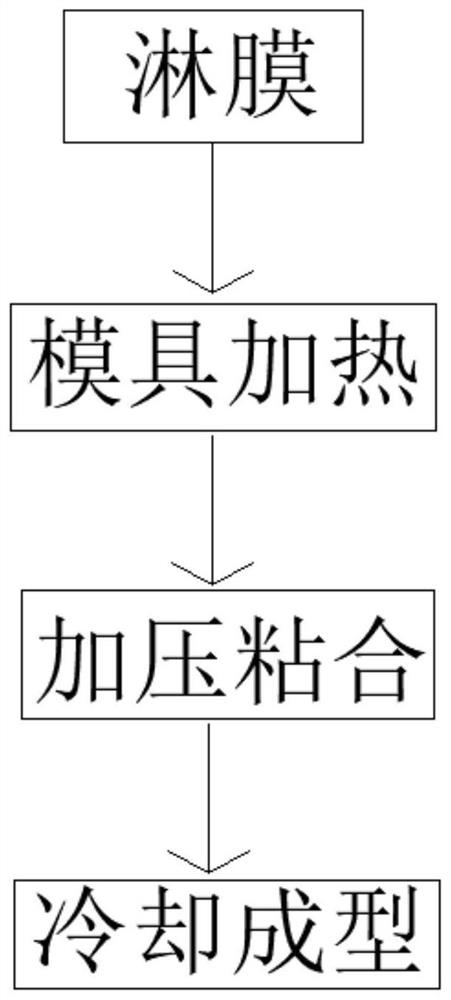

[0011] like figure 1 As shown, the present invention discloses a hot-pressing technology for making a double-layer kraft paper leak-proof garbage bag without glue. together; step four: cooling molding.

[0012] As a preferred technical solution of the hot pressing technology for making double-layer kraft paper leak-proof garbage bags without glue of the present invention, the specific operation of the step 1 is: put the kraft paper into the laminating machine for plastic laminating, plastic laminating The thickness of the layer is 0.1mm. The plastic coating layer of the kraft paper can make the paper surface waterproof. At the same time, the plastic coating layer on the surface of the kraft paper can play an adhesion role after heating.

[0013] As a preferred technical scheme of hot pressing technology for making double-layer kraft paper leak-proof garbage bags without glue in the present invention, the specific operation of the second step is: heating the hot pressing botto...

Embodiment 2

[0017] like figure 1 As shown, the present invention discloses a hot-pressing technology for making a double-layer kraft paper leak-proof garbage bag without glue. together; step four: cooling molding.

[0018] As a preferred technical solution of the hot pressing technology for making double-layer kraft paper leak-proof garbage bags without glue of the present invention, the specific operation of the step 1 is: put the kraft paper into the laminating machine for plastic laminating, plastic laminating The thickness of the layer is 0.25mm. The plastic coating layer of the kraft paper can make the paper surface waterproof. At the same time, the plastic coating layer on the surface of the kraft paper can play an adhesion role after heating.

[0019] As a preferred technical scheme of hot pressing technology for making double-layer kraft paper leak-proof garbage bags without glue in the present invention, the specific operation of the second step is: heating the hot pressing bott...

Embodiment 3

[0023] like figure 1 As shown, the present invention discloses a hot-pressing technology for making a double-layer kraft paper leak-proof garbage bag without glue. together; step four: cooling molding.

[0024] As a preferred technical solution of the hot pressing technology for making double-layer kraft paper leak-proof garbage bags without glue of the present invention, the specific operation of the step 1 is: put the kraft paper into the laminating machine for plastic laminating, plastic laminating The thickness of the layer is 0.5mm, and the plastic coating layer of kraft paper can make the paper surface waterproof, and at the same time, the plastic coating layer on the surface of kraft paper can play an adhesion role after heating.

[0025] As a preferred technical solution of the hot pressing technology for making double-layer kraft paper leak-proof garbage bags without glue in the present invention, the specific operation of the second step is: heating the hot pressing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com