Waste electric appliance auxiliary feeding device

A technology for electrical appliances and waste, which is applied in the direction of lifting devices, vacuum cleaners, suction nozzles, etc. It can solve the problems that small parts are easy to fall on the ground, increase the labor intensity of staff, and affect work efficiency, so as to eliminate potential safety hazards and reduce labor costs. Strength, work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

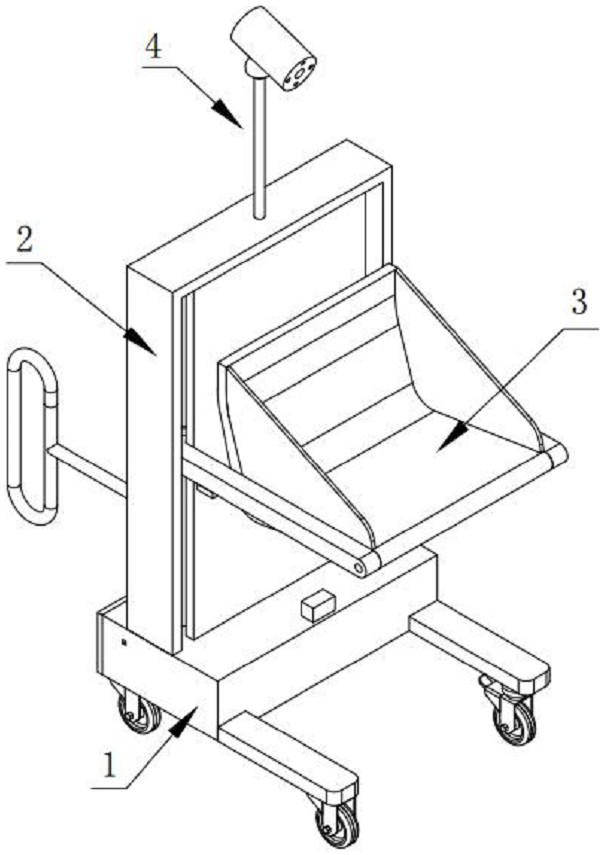

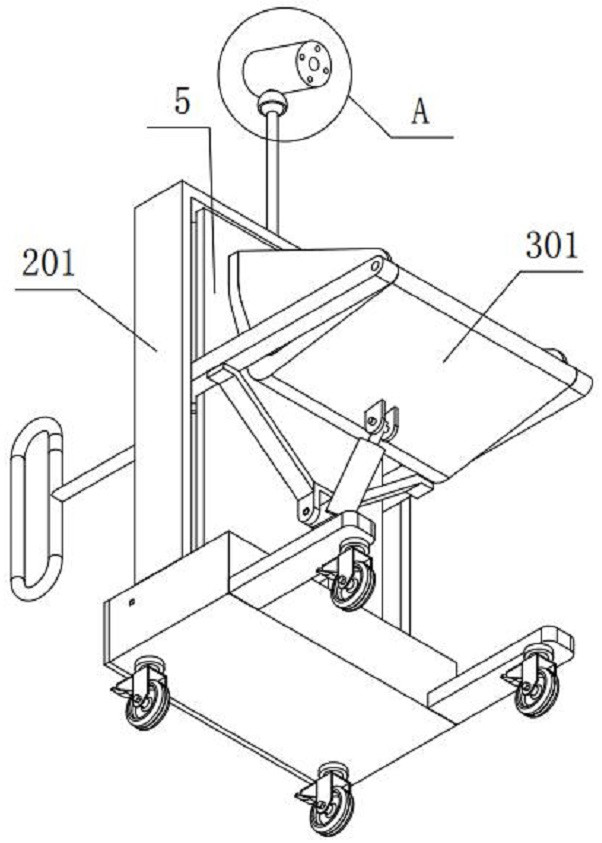

[0053] like figure 1 As shown, an auxiliary feeding device for waste electrical appliances is mainly composed of a bottom moving mechanism 1, a lifting mechanism 2, a feeding component 3, a monitoring mechanism 4 and a control mechanism.

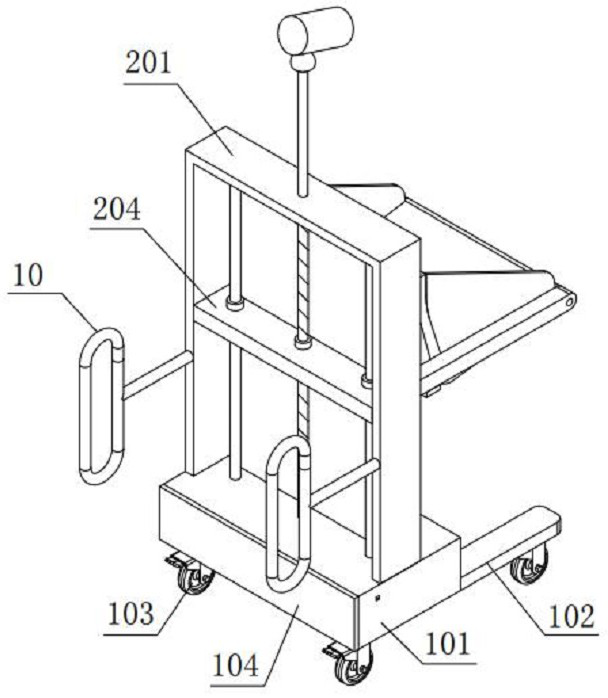

[0054] Among them, such as Figure 1-2 As shown, the bottom moving mechanism 1 is used to move the waste electric appliance auxiliary feeding device, and the set bottom moving mechanism 1 is composed of a base 101, two cross bars 102 and four universal wheels 103, and the inside of the base 101 is hollow. structure, and the side cover 104 is fixedly installed on the side of the base 101, the two cross bars 102 are fixed and horizontally installed on the side of the base 101 facing away from the side cover 104, and the two cross bars 102 are symmetrical Set, the four universal wheels 103 are symmetrically and fixedly installed on the bottom of the base 101 and the two cross bars 102, and the four universal wheels 103 are all set as self-lock...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap