A kind of colored polymer cement waterproof coating and preparation method thereof

A technology for waterproof coatings and polymers, applied in the field of building materials, can solve the problems of reducing the water resistance and poor dispersibility of waterproof coatings, and achieve the effects of excellent waterproof effect, good dispersibility, and increased surface active points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

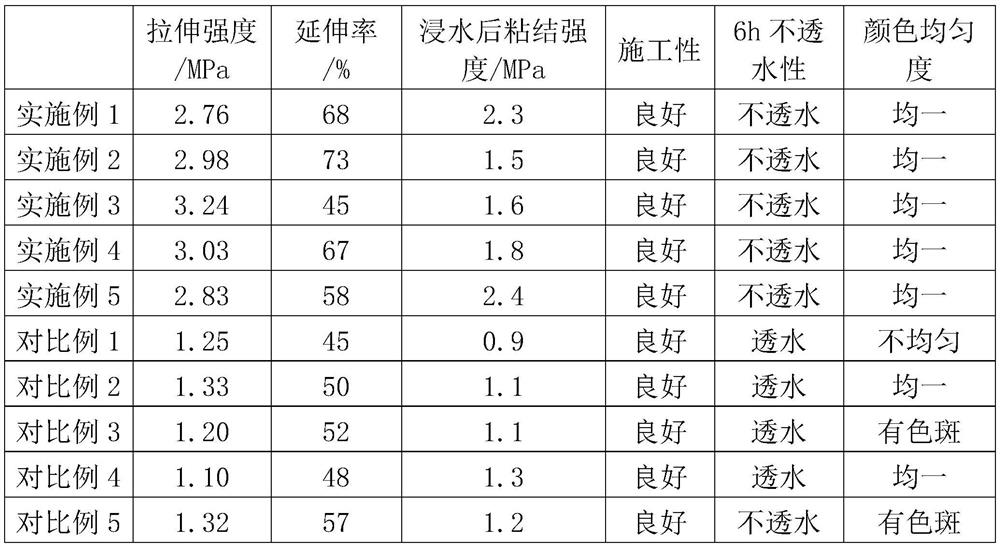

Examples

Embodiment 1

[0031] Prepare 100ml of silane coupling agent aqueous solution with a mass concentration of 1%, then add 50ml of 95% absolute ethanol solution, fully react for 20min in a water bath at 30°C, then add 10g of pigment powder, keep stirring, and gradually heat up to 50°C, Afterwards, heat preservation treatment for 2 hours, and finally suction filtration and drying at 105°C, and the dried solids were ground to obtain modified pigment powders;

[0032] Mix 5g of the modified pigment powder prepared above with 100g of water, stir until the solid dissolves, then add 100g of quartz sand for high-speed stirring, then let it stand for 24 hours, add 20g of EVA emulsion, continue stirring, and finally dry it at 70°C. Obtain pretreated quartz colored sand;

[0033] Place the pretreated quartz colored sand prepared above in a muffle furnace and first heat-preserve at 200°C for 2 hours, then gradually raise the temperature to 500°C for 2 hours at a heating rate of 5°C / min, and take it out af...

Embodiment 2

[0036] Prepare 100ml of silane coupling agent aqueous solution with a mass concentration of 1%, then add 50ml of 95% absolute ethanol solution, fully react for 10min in a water bath at 40°C, then add 10g of pigment powder, keep stirring, and gradually heat up to 70°C, Afterwards, heat preservation treatment for 2 hours, and finally suction filtration and drying at 105°C, and the dried solids were ground to obtain modified pigment powders;

[0037] Mix 10g of the modified pigment powder prepared above with 100g of water, stir until the solid dissolves, then add 100g of quartz sand for high-speed stirring, then let it stand for 24 hours, add 20g of EVA emulsion, continue stirring, and finally dry it at 70°C. Obtain pretreated quartz colored sand;

[0038] Place the pretreated quartz colored sand prepared above in a muffle furnace and first heat-preserve at 200°C for 2 hours, then gradually raise the temperature to 500°C for 2 hours at a heating rate of 5°C / min, and take it out a...

Embodiment 3

[0041] Prepare 100ml of silane coupling agent aqueous solution with a mass concentration of 1%, then add 50ml of 95% absolute ethanol solution, fully react for 10min in a water bath at 30°C, then add 10g of pigment powder, continue stirring, and gradually heat up to 60°C, Afterwards, heat preservation treatment for 2 hours, and finally suction filtration and drying at 105°C, and the dried solids were ground to obtain modified pigment powders;

[0042] Mix 7g of the modified pigment powder prepared above with 100g of water, stir until the solid is dissolved, then add 100g of quartz sand for high-speed stirring, then let it stand for 24 hours, add 20g of EVA emulsion, continue stirring, and finally dry it at 70°C. Obtain pretreated quartz colored sand;

[0043] Place the pretreated quartz colored sand prepared above in a muffle furnace and first heat-preserve at 200°C for 2 hours, then gradually raise the temperature to 500°C for 2 hours at a heating rate of 5°C / min, and take it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com