Modified cross-linked polyamide polyamine cylinder adhesive applicable to low temperature and preparation method thereof

A technology of polyamide polyamine and sticking agent, which is applied in the field of sticking agent for papermaking, which can solve the problems of hard coating, etc., and achieve the effect of reducing energy consumption and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

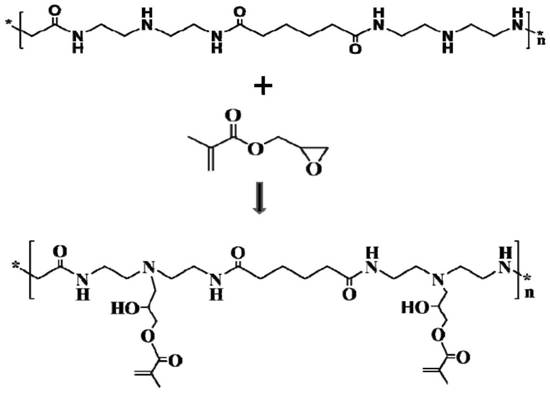

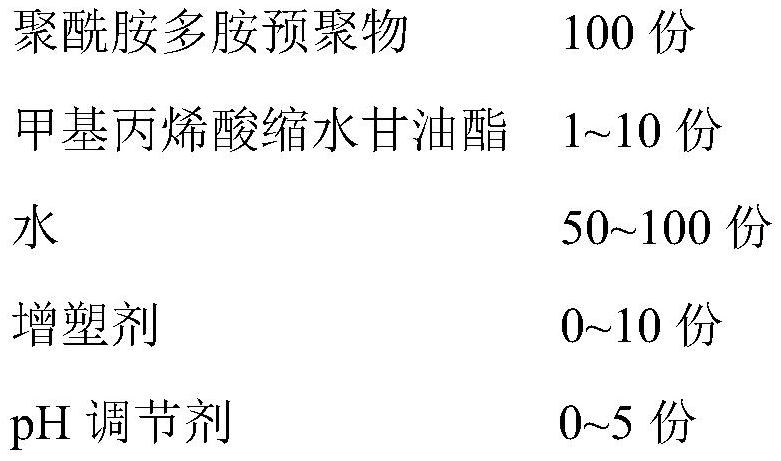

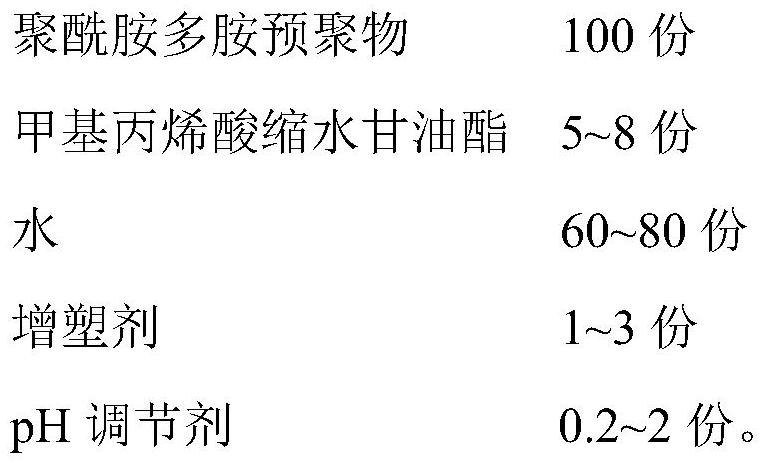

Method used

Image

Examples

preparation example Construction

[0027] The preparation of solid content 37% polyamide polyamine prepolymer:

[0028] Add 491.4g of diethylenetriamine to the four-necked flask, and add 672.57g of adipic acid into the four-necked flask at a uniform speed under stirring, control the speed of the added adipic acid so that the adipic acid can be dispersed uniformly in the bottle, add After the adipic acid is controlled to raise the temperature in the oil bath stage, observe and record the temperature in the bottle, build a distillation device, control the temperature at 175°C, and observe the situation in the bottle to see if water is coming out, record the time of water coming out, and keep it warm for 6 hours after the water is out, and the receiving system is evaporated The moisture that goes out is also recorded by weighing; After the reaction finishes, weigh the Erlenmeyer flask weight and record, add 846g deionized water to terminate the reaction, finally add 866g deionized water to adjust the polyamide poly...

Embodiment 1

[0030] Put 320g of polyamide polyamine prepolymer with a solid content of 37% in a four-necked bottle, start mechanical stirring, set the rotation speed at 180r / min, set the reaction temperature at 60°C, and add 1.84g of it dropwise when the system temperature reaches the set temperature. The joint agent GMA was kept at this temperature for 3 hours until the viscosity of the system was stable and did not continue to increase. Then 85% phosphoric acid was added to adjust the pH to 7.5 to terminate the reaction, and 470 g of deionized water was added to stir and store for later use.

Embodiment 2

[0032] Put 320g of polyamide polyamine prepolymer with a solid content of 37% in a four-necked bottle, start mechanical stirring, set the rotation speed at 180r / min, set the reaction temperature at 60°C, and add 3.69g of it dropwise when the system temperature reaches the set temperature. The joint agent GMA is kept at this temperature for 3 hours until the viscosity of the system is stable and does not continue to increase. Add 85% phosphoric acid to adjust the pH=7.5 to terminate the reaction and add 470g of deionized water to stir and store for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com