Novel hub type assembly type scaffold and fastener

A scaffolding and assembly technology, which is applied in the connection of scaffolding, construction, building structure support, etc., can solve the problems of easy loss of fasteners, complicated construction, etc., and achieve the effects of rapid construction, shortened construction period, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

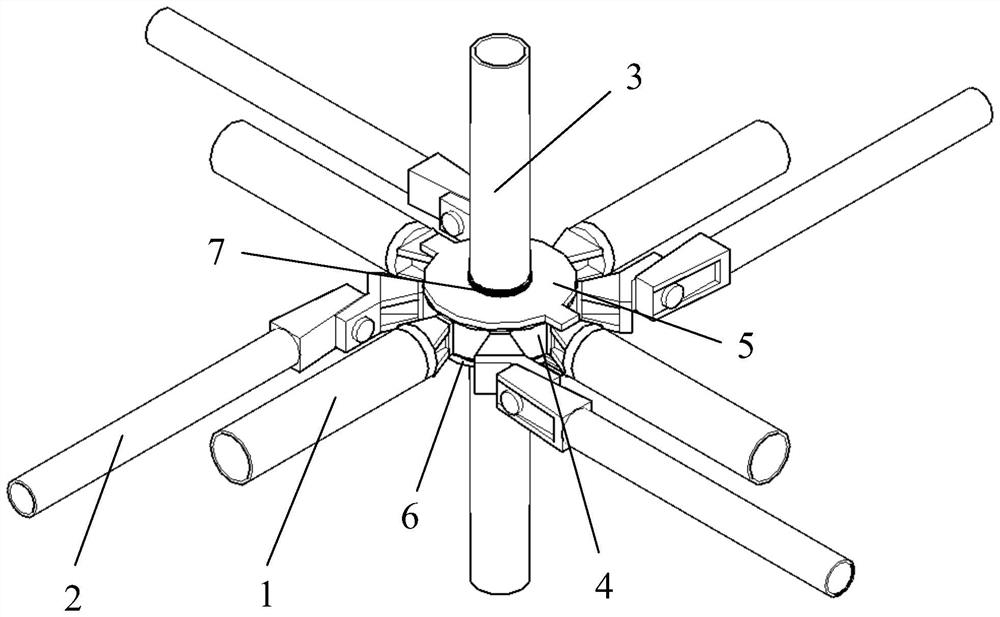

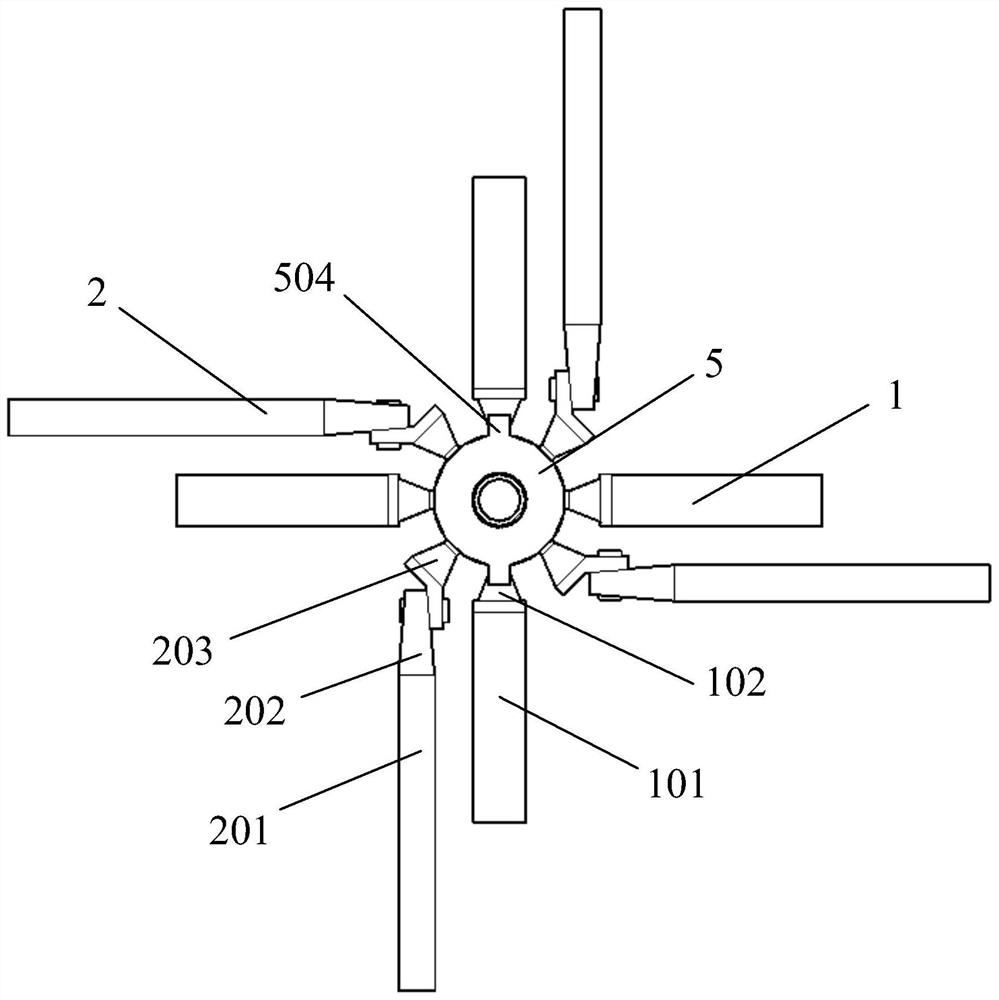

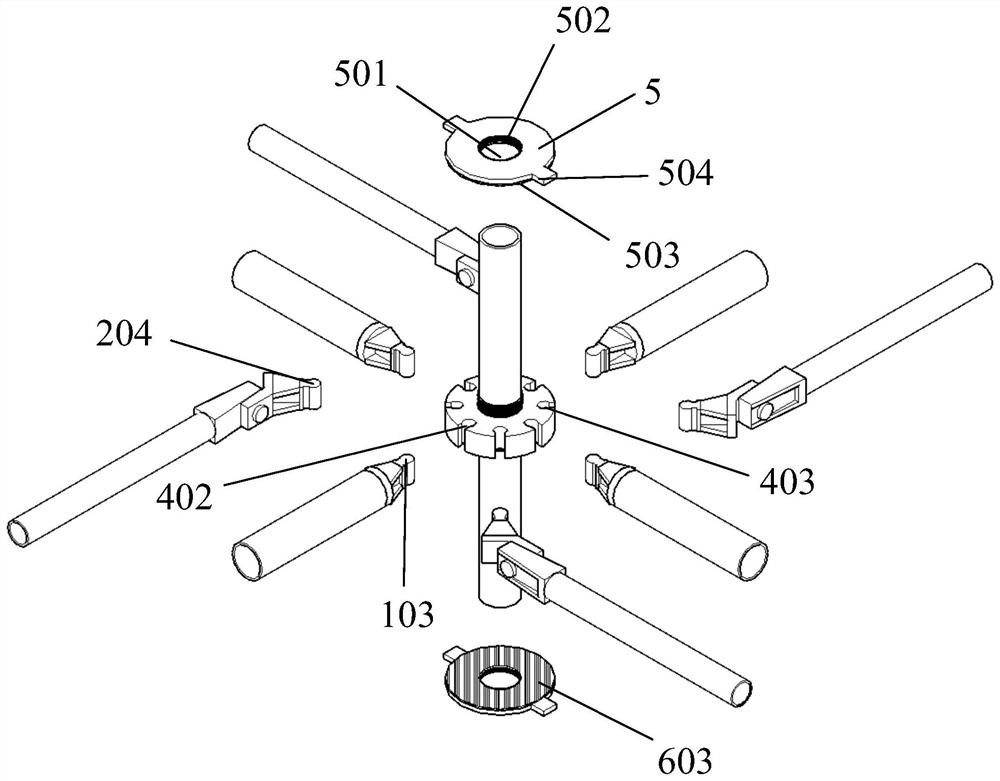

[0024] Such as Figure 1-Figure 7 As shown, it includes a horizontal bar 1, an oblique bar 2, a vertical bar 3, a hub-type circular disc 4, an upper cover plate 5 and a lower cover plate 6, and the horizontal bar 1 includes a horizontal steel pipe 101 and a horizontal bar connector 102 and convex plug I103, the horizontal steel pipe 101, the horizontal rod connector 102 and the male plug I103 are connected by welding, and the oblique rod 2 includes the oblique steel pipe 201, the oblique rod connector I202, the oblique rod connector II203 and the convex shaped plug II204, the oblique steel pipe 201 is welded to the oblique rod connector I202, the oblique rod connector II203 is welded to the convex plug II204, and the oblique rod connector I202 and the oblique rod connector II203 are The hinged connection realizes the adjustment of the vertica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com