Packer and well completion structure

A technology of packer and isolation piston, which is applied in the directions of sealing/packing, wellbore/well components, wellbore/well valve device, etc. Diameter and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

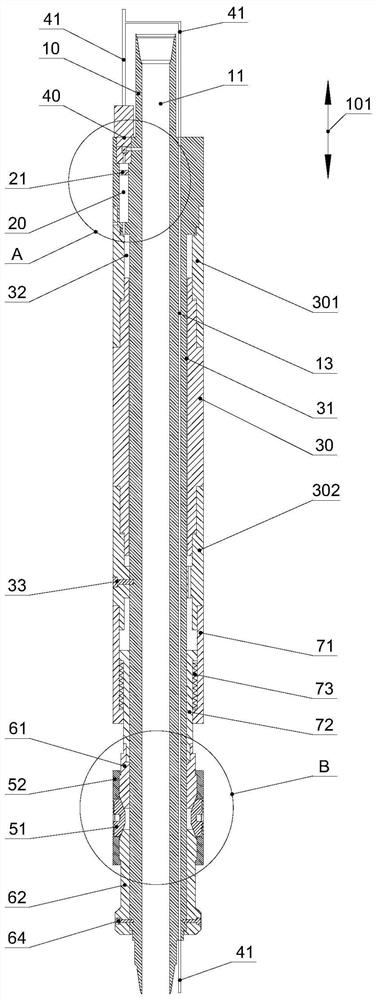

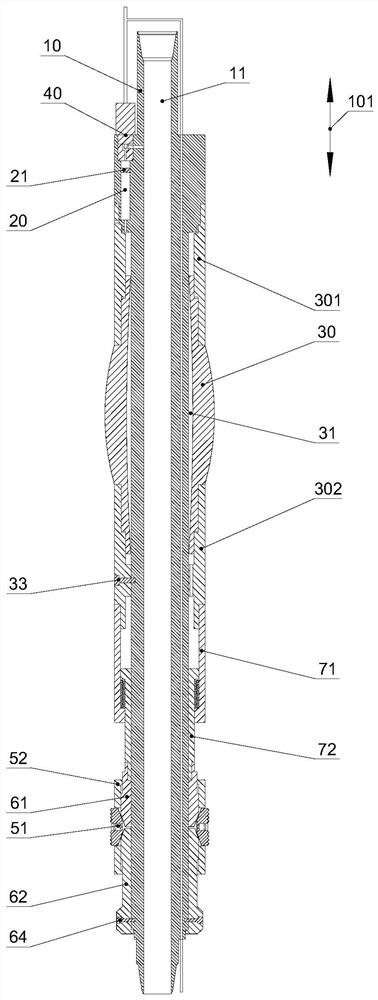

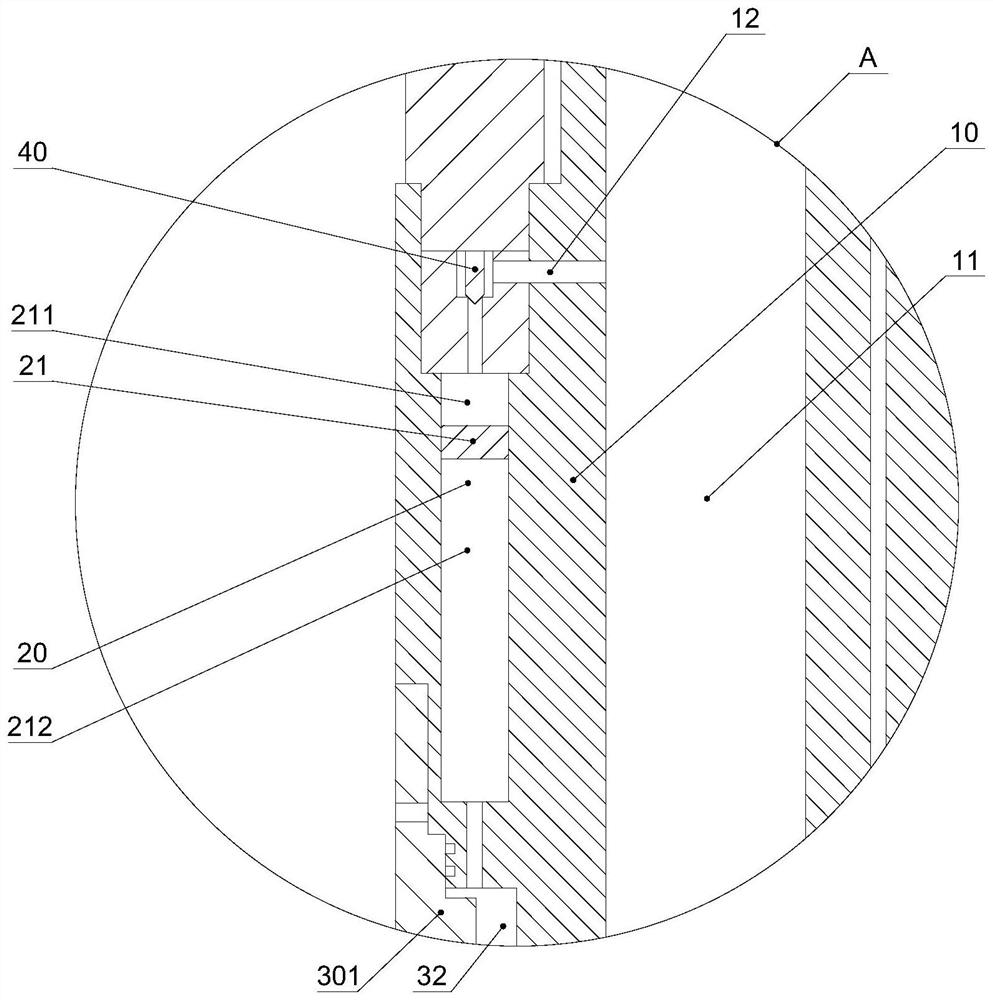

[0048] The present invention provides a packer, such as figure 1As shown, the packer includes: a pipe body 10, a rubber sleeve 30 and an electric control valve 40; the rubber sleeve 30 is sleeved outside the pipe body 10; the pipe body 10 is provided with a piston cavity 20; the electric control valve 40 is arranged on the pipe body 10. The electric control valve 40 communicates with the piston cavity 20 and the tube cavity 11 of the tube body respectively, and is used to control the on-off between the piston cavity 20 and the tube cavity 11 of the tube body; the piston cavity 20 is provided with an isolation piston 21, The pressure liquid in the lumen 11 of the tube body can enter the piston chamber 20 through the electric control valve 40 to push the isolation piston 21 to move, and the isolation piston 21 drives the outer diameter of the rubber cartridge 30 to expand outward. The electric control valve 40 can be a normally open valve or a normally closed valve. Preferably,...

Embodiment 2

[0075] The present invention provides a well completion structure, such as Figure 5 As shown, the well completion structure includes: tubing 2; at least one above-mentioned packer 1 arranged along the tubing 2; production distribution device 3, and distribution devices 3 are provided on both sides of the packer 1 respectively.

[0076] In this well completion structure, the surface pump truck is used to pressurize the oil pipe 2, and the pressure liquid in the oil pipe 2 is used to provide the driving force for setting, and the electric control valve 40 is used to control the setting, and the packer is omitted The motor and other power components are installed in the main body of the packer 1, which simplifies the structure of the packer 1, helps to reduce the space occupied by the mechanical parts in the packer 1, facilitates the realization of a larger inner diameter, and helps to improve the reliability of the control .

[0077] In one embodiment, as Figure 5 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com