Method of removing silver by adding magnesium to silver-containing tin alloy

A silver-tin alloy and magnesium alloy technology, applied in the field of non-ferrous metal pyrometallurgy, can solve the problems of inability to handle high-lead solder, high capital construction investment cost, inability to obtain purity, etc., and achieves improved resource utilization, convenient operation, lively effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

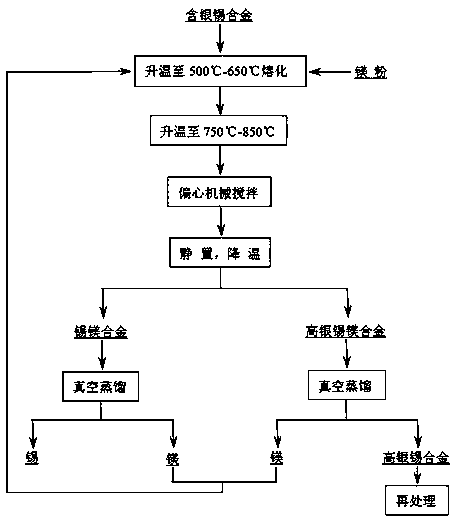

[0020] Such as figure 1 Shown, this adds magnesium to the method for removing silver in silver-containing tin alloy, and its concrete steps are as follows:

[0021] Step 1. First, heat 5t of silver-containing tin alloy (the content of silver in the silver-containing tin alloy is 1.0g / t, and the rest is tin) to 500°C to fully melt, and according to the molar ratio of tin and magnesium in the silver-containing tin alloy: 1: 3 Add magnesium, and pass argon into the crucible (argon flow rate is 1Nm 3 / h) local gas protection;

[0022] Step 2. Continue to heat up to 750°C, stir with eccentric mechanical stirring (the stirring speed of eccentric mechanical stirring is 600r / min) for 20 minutes, let it stand for 40 minutes, and after cooling down to room temperature, the lower layer of tin-magnesium alloy with obvious layering phenomenon (silver content 0.1g / t) and the upper layer of high-silver tin-magnesium alloy.

[0023] The tin-magnesium alloy in the lower layer of the above s...

Embodiment 2

[0025] Such as figure 1 Shown, this adds magnesium to the method for removing silver in silver-containing tin alloy, and its concrete steps are as follows:

[0026] Step 1. First, heat 5t of silver-containing tin alloy (the content of silver in the silver-containing tin alloy is 500g / t, and the rest is tin) to 600°C to fully melt, and follow the molar ratio of tin to magnesium in the silver-containing tin alloy of 1:2 Add magnesium, and pass argon in the crucible (argon flow rate is 0.5Nm 3 / h) local gas protection;

[0027] Step 2. Continue to heat up to 800°C, eccentric mechanical stirring (stirring speed of eccentric mechanical stirring is 600r / min) for 30 minutes, let stand for 50 minutes, and after cooling down to room temperature, the lower layer of tin-magnesium alloy with obvious layering phenomenon (silver content 0.2g / t) and the upper layer of high-silver tin-magnesium alloy.

[0028] The tin-magnesium alloy in the lower layer of the above step 2 is vacuum distill...

Embodiment 3

[0030] Such as figure 1 Shown, this adds magnesium to the method for removing silver in silver-containing tin alloy, and its concrete steps are as follows:

[0031] Step 1. First, heat 5t of silver-containing tin alloy (the content of silver in the silver-containing tin alloy is 50,000g / t, and the rest is tin) to 650°C to fully melt, and follow the molar ratio of tin to magnesium in the silver-containing tin alloy of 1:1 Add magnesium, and pass argon in the crucible (argon flow rate is 0.8Nm 3 / h) local gas protection;

[0032] Step 2. Continue to heat up to 850°C, eccentric mechanical stirring (stirring speed of eccentric mechanical stirring is 100r / min) for 25 minutes, let stand for 60 minutes, and after cooling down to room temperature, the lower layer of tin-magnesium alloy with obvious layering phenomenon (silver content 0.8g / t) and the upper layer of high-silver tin-magnesium alloy.

[0033] The tin-magnesium alloy in the lower layer of the above step 2 is vacuum dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com