Leakage petroleum recovery method and special equipment

A special equipment and oil technology, applied in the field of spilled oil recovery methods and special equipment, can solve the problems of low collection efficiency, increased cleaning costs, marine pollution, etc., and achieve the effects of easy secondary use, convenient operation, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

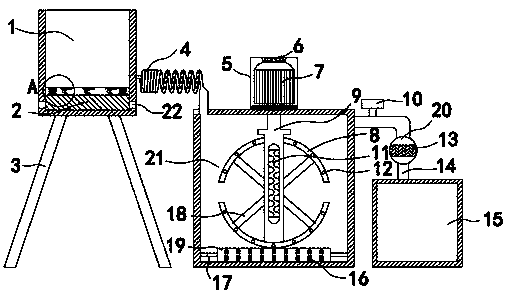

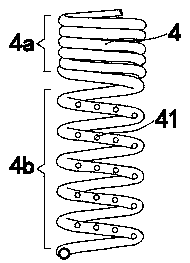

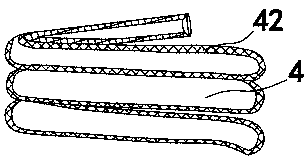

[0026] like Figure 1~4 As shown, a special equipment for recovery of leaked oil includes a static tank 1, a primary filter chamber 21, and a fine filter chamber 20. The bottom of the static tank 1 is supported by a support frame 3, and the static tank 1 is connected to the fine filter through a spiral oil outlet pipe 4. Chamber 21, fine filter chamber 21 inside is provided with a stirring device, the right side of fine filter chamber 21 is connected to oil collection pool 15 tops by bent pipe 14, and the vertical end of bent pipe 14 is provided with fine filter chamber 20, and bent pipe 14 The lateral end is provided with a control valve 10 . This device can recycle and filter oil, and the filtered oil can be used again. Oil filtration is divided into three steps, namely rapid oil-water separation, adsorption of magnetic impurities in oil and reduction of oil viscosity, and filtration of tiny particles in oil. , the filtration process is short, and the filtered oil has high ...

Embodiment 2

[0039] When the leaked oil recovery method and the special equipment of the present invention are actually used: the oil is first collected in the static pool 1, and the water sinks to the bottom of the pool through sedimentation, and the oil floats on the water surface to realize the stratification of the oil, and at the same time The large stones and debris contained in the oil will sink into the collection box 2 for centralized treatment. The high-frequency vibration device can accelerate the oil-water stratification in the static tank 1, and the vibration amplitude is small, and the dehydrated oil After entering the primary filter chamber 21, the stirring device stirs the oil, and the motor 7 is energized to drive the rotating shaft 9 to rotate rapidly, stirring the oil back and forth, effectively reducing the viscosity of the oil. The bottom of the primary filter chamber 21 is provided with a roller 19, which The magnetic block 16 on the surface of 19 can adsorb metal part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com