A gearless coupling and multi-angle screwdriver

A screwdriver and multi-angle technology, applied to screwdrivers, couplings, elastic couplings, etc., can solve the problems of high manufacturing cost, inconvenient, complex structure, etc., to improve aesthetics, save labor and reduce work difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

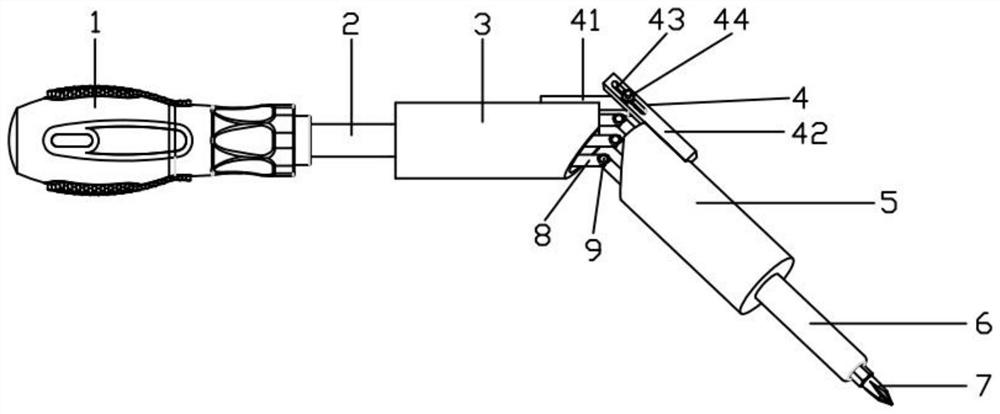

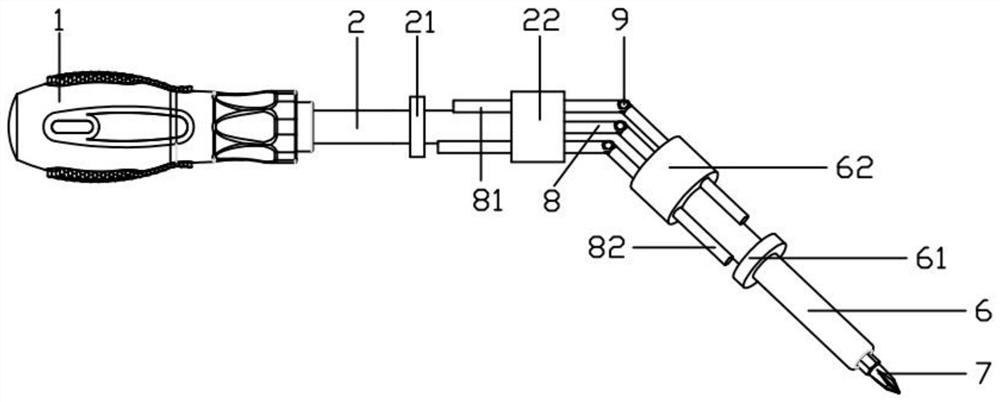

Embodiment 1

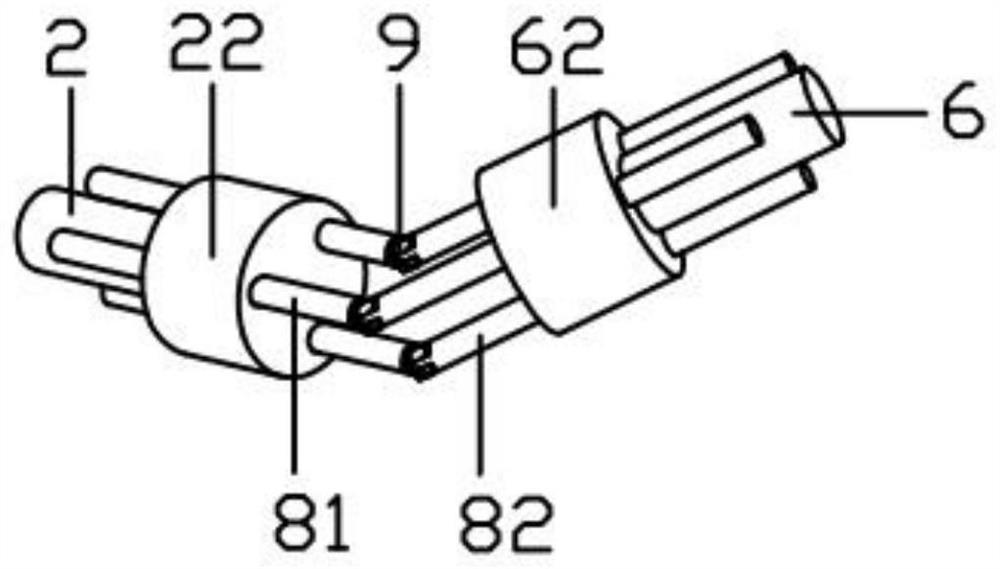

[0053] image 3 Shown is a gearless coupling in this embodiment, including a first rotor 2, a second rotor 6 and three connecting rods 8; the end of the first rotor 2 is sleeved with a first turntable 22; the A second turntable 62 is sleeved on the end of the second rotor 6; the connecting rod 8 includes a driving rod 81 and a driven rod 82; the driving rod 81 and the driven rod 82 have an included angle when they are connected; 81 penetrates into the outer edge of the first turntable 22 and slides with the first turntable 22; the driven rod 82 penetrates into the outer edge of the second turntable 62 and slides with the second turntable 62. The distance between the axis of a turntable 22 is equal to the distance between the driven rod 82 and the axial center of the second turntable 62 . The driving rod 81 rotates with the first turntable 22 and the driven rod 82 drives The direction of rotation of the second turntable 62 is the same, and both are clockwise or counter-clockwi...

Embodiment 3

[0079] A method of using a multi-angle screwdriver, the specific steps are as follows: adjust the angle between the driving rod 81 and the driven rod 82, make the movable cutter head 7 close to the screw and fit, and stabilize the first turntable 22 and the second turntable 62. Turn the handle 1 to drive the first rotor 2 and the first turntable 22 at the end to rotate, the first turntable 2 drives the driving rod 81 and the driven rod 82 to rotate, and transmits the torque to the second turntable 62, so that the The second turntable 62 and the second rotor 6 coaxially fixed to the second turntable 62, the movable cutter head 7 coaxially fixed to the second rotor 6, and the screw matched with the movable cutter head 7 rotate, so that the screw is fastened or loose.

Embodiment 4

[0081] The using method of the present invention is as follows:

[0082] A method of using a multi-angle screwdriver, the specific steps are as follows: rotate the handle 1 to drive the movable cutter head 7 to rotate to tighten the bolt; adjust the sleeve adjustment member 4 to make the handle 1 and the movable cutter head 7 at a suitable angle, and then tighten the nut 44 for fixing; rotating the handle 1 drives the first rotor 2 to rotate, the first rotor 2 drives the first turntable 22 to rotate, the first turntable 22 drives the connecting rod 8 to rotate, and the connecting rod 8 drives the second turntable 62 When rotating, the second turntable 62 drives the second rotor 6 to rotate, and the second rotor 6 drives the movable cutter head to rotate; finally, the screw is tightened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com