Water hose with holes and preparation method of water hose

A technology of water hose and hydrophilic polymer, which can be used in mechanical equipment, textiles, fabrics, etc., and can solve problems such as fire hose damage and fiber layer damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

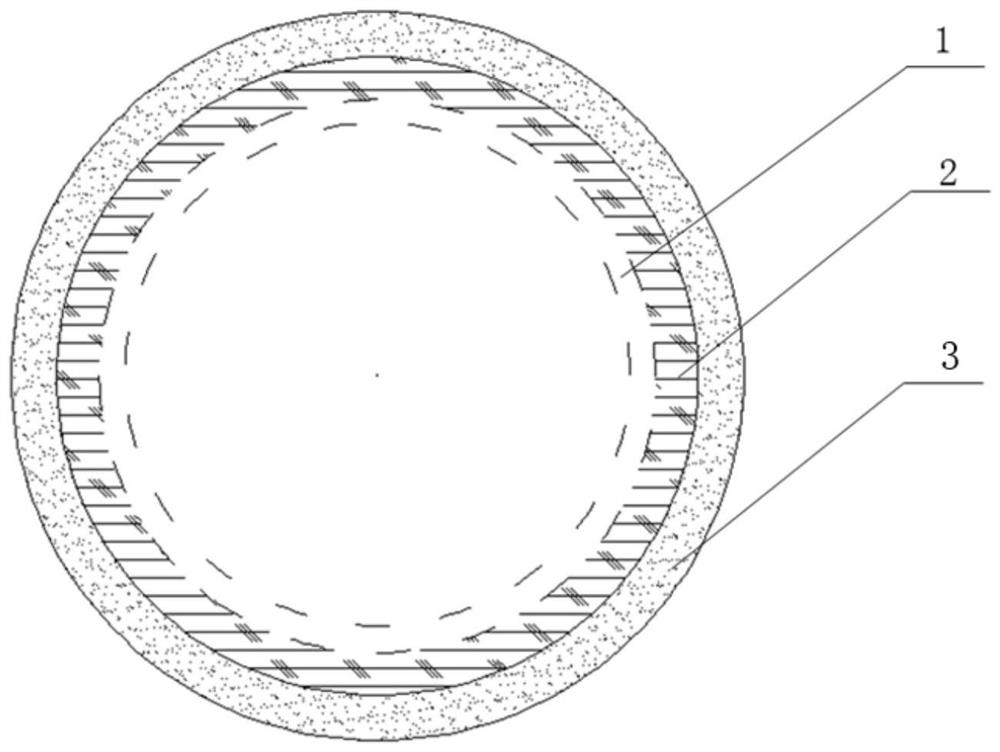

[0026] A hose with holes, its structure from the inside to the outside is like figure 1 As shown, it includes an infiltration layer 1, a braided layer 2 and an outer fiber layer 3; the infiltration layer 1 has holes that allow water to leak (the infiltration layer 1 with holes is represented by a dotted line); the braided layer 2 It has the function of water absorption and can control the amount of water seepage;

[0027] Wherein the braided layer 2 has the function of absorbing water and thus can control the technical effect of water seepage through the following features: the warp and weft fibers of the braided layer 2 adopt cotton-type fibers, and the cotton-type fibers have certain water-absorbing swelling properties. When the water with a fixed working pressure passes through, the cotton-type fiber has a certain water absorption function for the passing water and then expands to make the gap in the braided layer narrow, thereby controlling the water seepage on the surface...

Embodiment 2

[0037] The structure of the hose with holes in this embodiment includes an infiltration layer 1, a braided layer 2, an outer fiber layer 3, and an outer glue layer from the inside to the outside.

[0038] The preparation process of the hose with holes in this embodiment is the same as that of Embodiment 1, except that in step (3), a layer of rubber-plastic alloy outer rubber layer is extruded outside the outer fiber layer 3 .

Embodiment 3

[0040] The structure of the hose with holes in this embodiment includes an infiltration layer 1 and a braided layer 2 in sequence from the inside to the outside.

[0041] The preparation process of the hose with holes in this embodiment is the same as in Example 1, the difference is that

[0042] (1) Extrude and coat PVP K60 on cotton-type polyester staple fiber to obtain a modified warp fiber with a hydrophilic polymer film layer;

[0043] (2) 10 strands of the modified warp fibers are evenly distributed in 240 strands of warp fibers and cross-woven with 250 strands of weft fibers to obtain braided layer 2. Braided layer 2 is plain weave, warp-oriented fibers and weft The fibers are made of cotton-type polyester filament fibers;

[0044] The diameter of the hose obtained in this embodiment is 40mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Vertical thickness | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com