Self-propelled water conservancy pipeline slag removal device for water conservancy project and implementation method thereof

A water conservancy project, self-propelled technology, applied in the direction of cleaning methods and appliances, chemical instruments and methods, pipe components, etc., can solve the problems of slow efficiency, difficult removal of impurities and rust on the surface of the pipe, and low cleaning quality inside the pipe. Achieve good cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach , 1 Embodiment approach

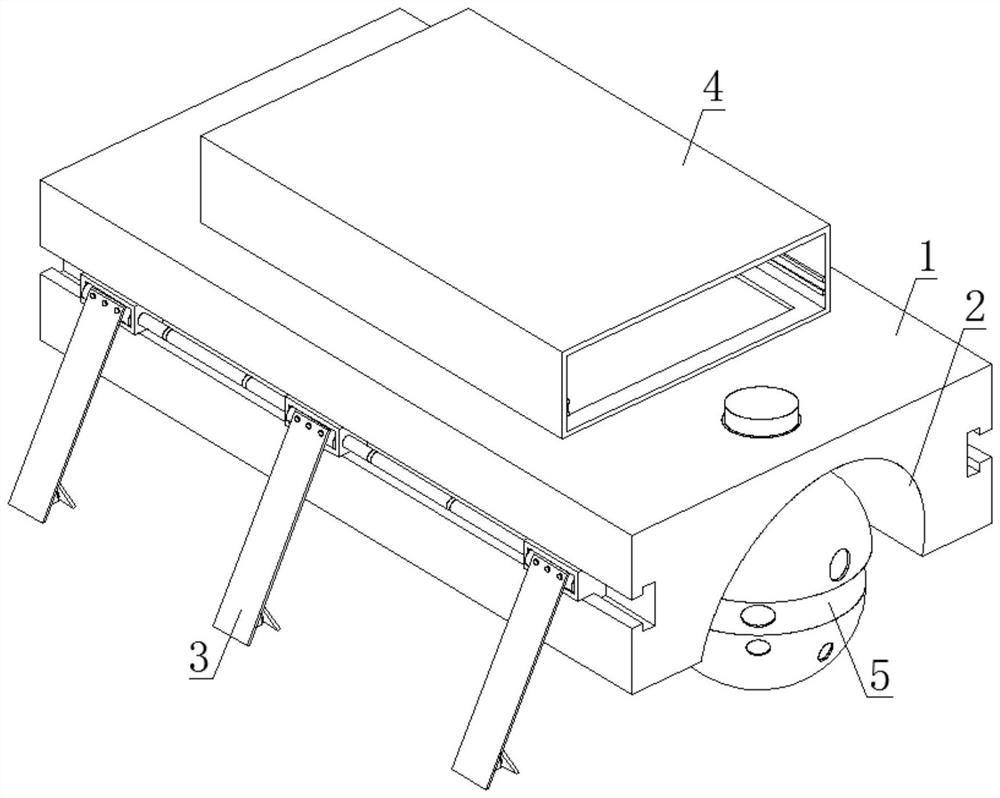

[0044] In order to further and better explain the above-mentioned embodiments, the present invention also provides an embodiment, a method for implementing a self-propelled hydraulic pipeline slag removal device for water conservancy projects, comprising the following steps:

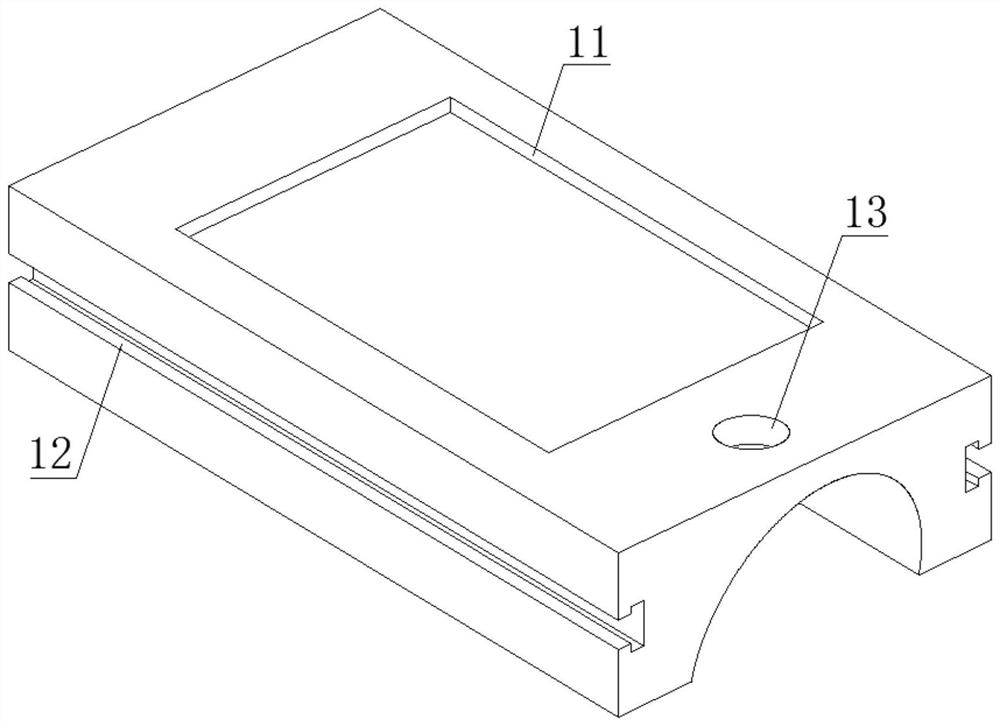

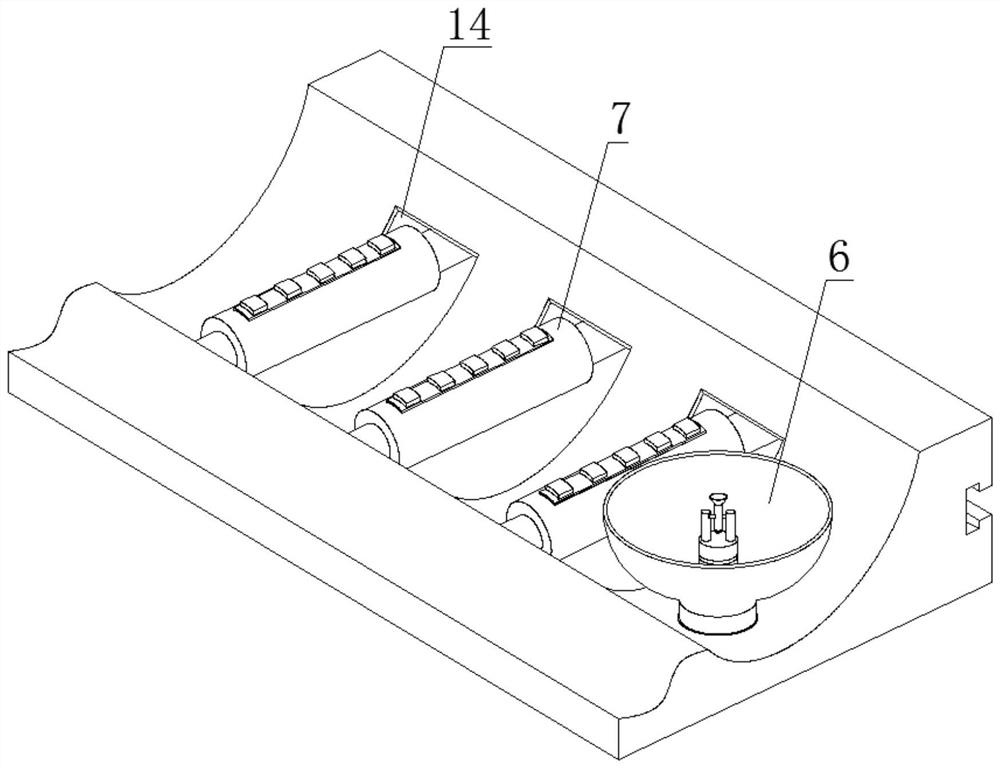

[0045] Step 1: the main box 1 is placed on the outer surface of the pipeline to be cleaned, and the cleaning mechanism 5 is placed on the inside of the pipeline to be cleaned as a whole, and the docking cover 61 is taken off simultaneously;

[0046] Step 2: Use the electric push rod 16 to move the erasing cylinder 71 to the outer surface of the pipeline to be cleaned, and ensure that the erasing block 751 can be in contact with the outer surface of the pipeline to be cleaned, and then use the displacement mechanism 3 to enable the main box 1 to The surface of the pipeline to be cleaned is moved to realize the cleaning of the surface of the pipeline to be cleaned;

[0047] Step 3: When the erasing block 7...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap