Metallographic preparation device for material science and engineering

A material science and preparation device technology, applied in the field of material science and engineering, can solve the problems of operator fatigue, troublesome operation, inconvenient metallographic sample production, etc., to reduce friction and facilitate grinding and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

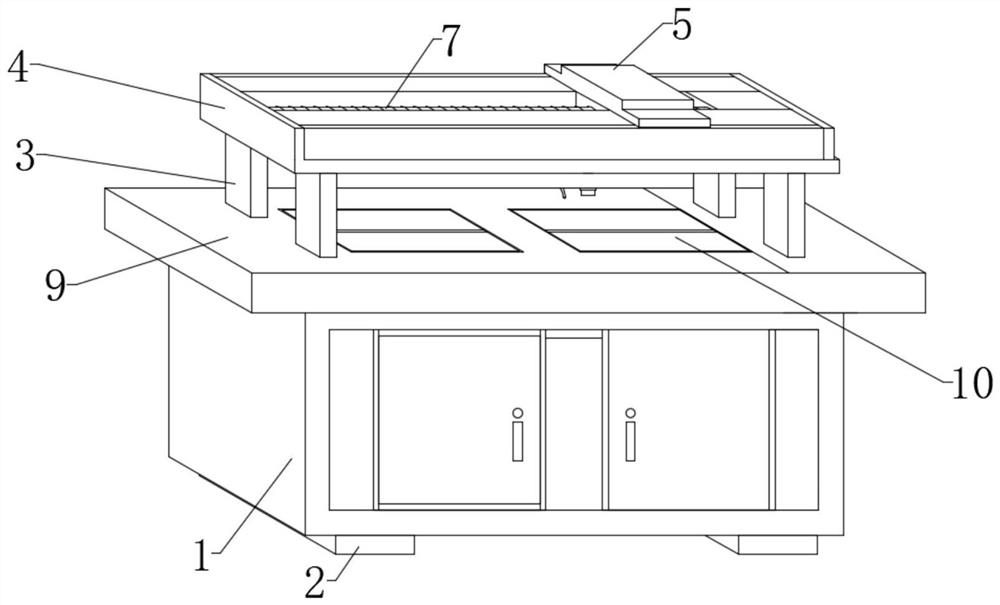

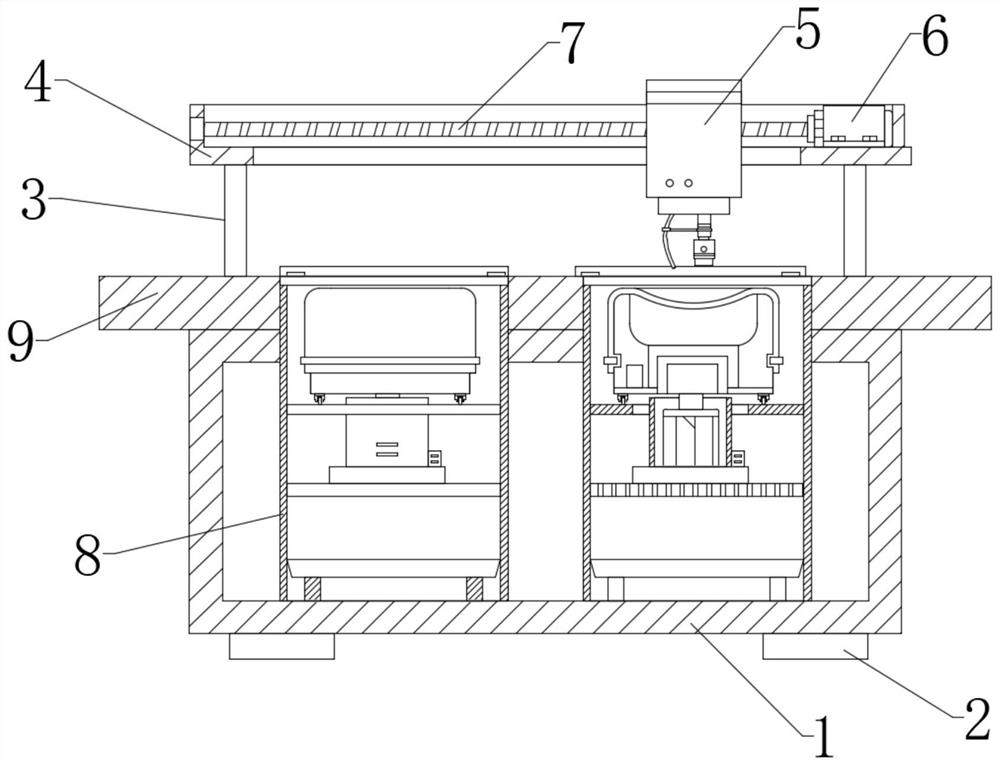

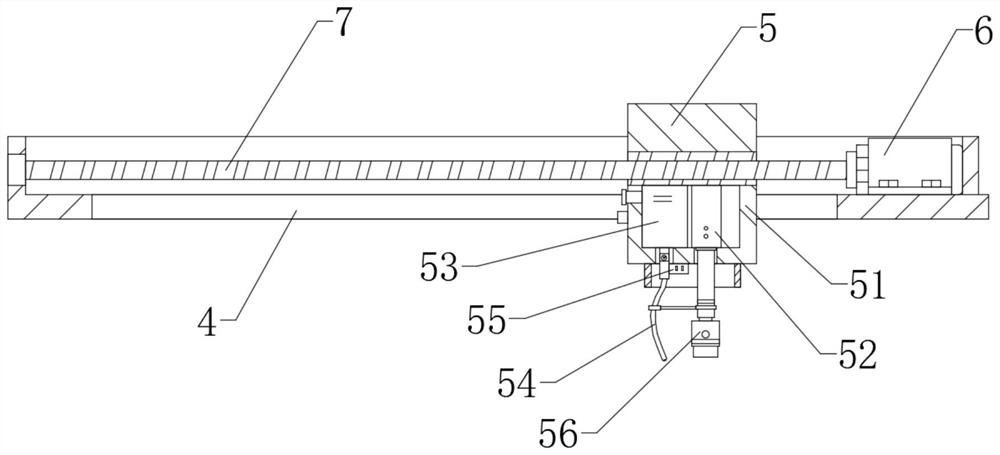

[0028] see Figure 1-4 , a metallographic preparation device for material science and engineering, comprising a box body 1, support feet 2 are installed on both sides of the lower end of the box body 1, a workbench 9 is fixedly installed on the upper end of the box body 1, and the four corners of the upper end of the workbench 9 are fixed Connected with support column 3, the upper end of support column 3 is fixedly connected with fixed seat 4, is slidably connected with sliding seat 5 on the fixed seat 4, and is threadedly connected with screw mandrel 7 on the inner upper part of slide seat 5, and one end of screw mandrel 7 avoids with the inner side of fixed seat 4. Rotate connection, the other end of the screw rod 7 is equipped with a motor one 6, and the motor one 6 is fixed on the lower end of the fixed seat 4; a telescopic rod 52 is installed in the lower part of the slide seat 5, and a mounting head 56 is fixedly installed on the lower end of the telescopic rod 52, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com