Multi-level direct current fault arc detection method based on parameter matching

A fault arc and DC fault technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of optimal matching, no multi-link parameters, and no multi-dimensional goals of DC fault arc detection performance. Ensuring efficiency, improving reliability and speed, and reducing computing resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. The examples are only used to explain the present invention, not to limit the protection scope of the present invention.

[0039] (1) Accurate detection of multi-level DC fault arc

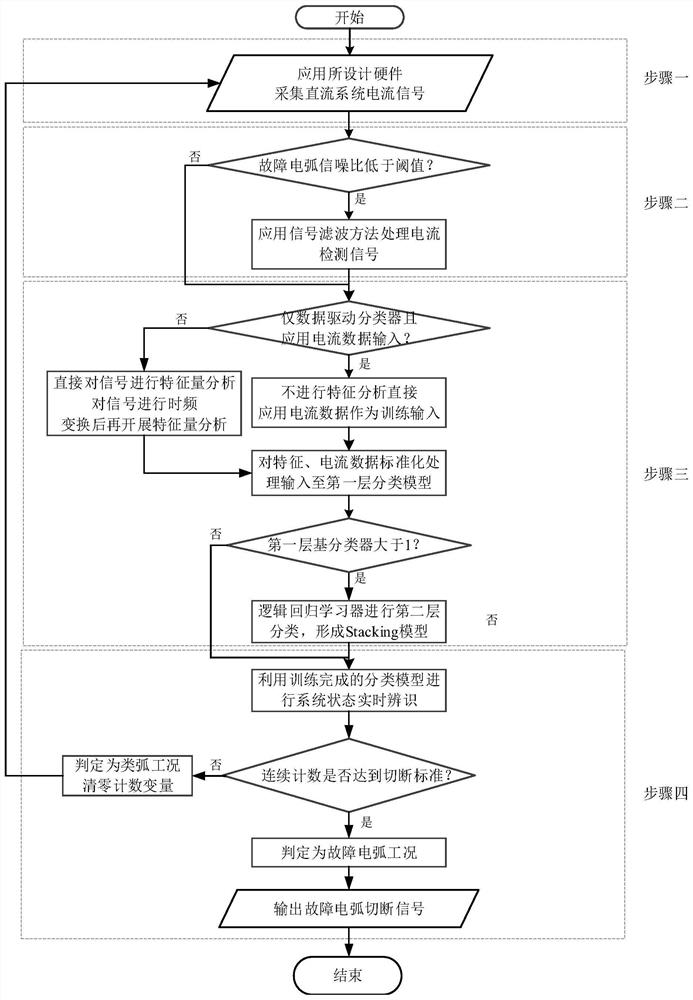

[0040] The process of accurate detection of multi-level DC fault arc adopted by the present invention is as follows: figure 1 As shown, the specific steps are as follows:

[0041] Step 1. During the operation of the DC system, the fault arc detection hardware samples current signals under normal interference and fault arc conditions of the DC system at a frequency f to form a detection signal data set, and go to step 2;

[0042] The data set considers the interference of power electronic devices, the operation of purely resistive loads, the fault arc current under the condition of long-distance transmission, and the fault arc current under the condition of two-bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com