Sample tray transfer tracing system and method

A technology of traceability system and samples, applied in transportation and packaging, conveyor objects, business, etc., can solve the problems of tight time, low efficiency of manual inspection, affecting the traceability of samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

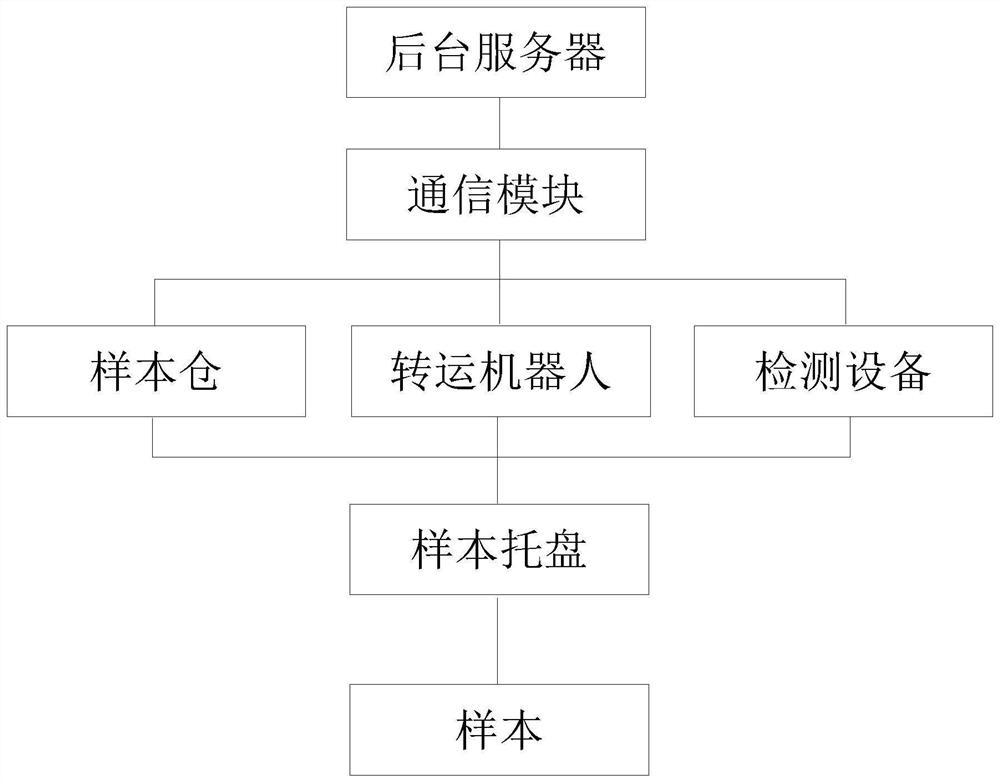

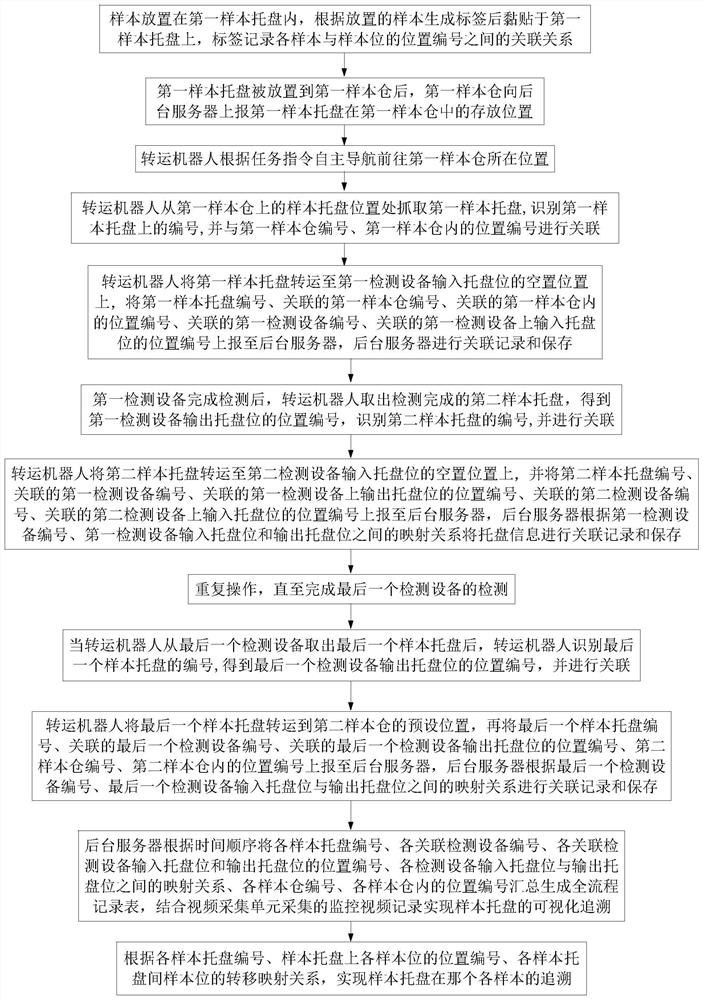

[0030] A sample tray transfer traceability system, such as figure 1 As shown, several sample trays, several sample bins, several transfer robots, several detection devices, background servers and communication modules. The samples to be tested and tested are placed in the sample tray, and the background server dispatches a number of transfer robots to transfer the sample tray between each testing device and the sample chamber, and between each testing device. Generally speaking, the samples to be tested and the samples that have been tested are placed in different sample compartments, and the samples are sequentially processed or tested in each testing equipment. The testing equipment of the present invention includes testing equipment in a narrow sense, such as Microbiological testing equipment, concentration testing equipment, etc., as well as sample processing equipment, such as separation and purification equipment, refrigeration equipment, microbial cultivation equipment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com