LED lamp bead

A technology of LED lamp beads and LED chips, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of silicone inflow, failure, and improve the difficulty of packaging silicone at the output end, and achieve the effect of improving convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

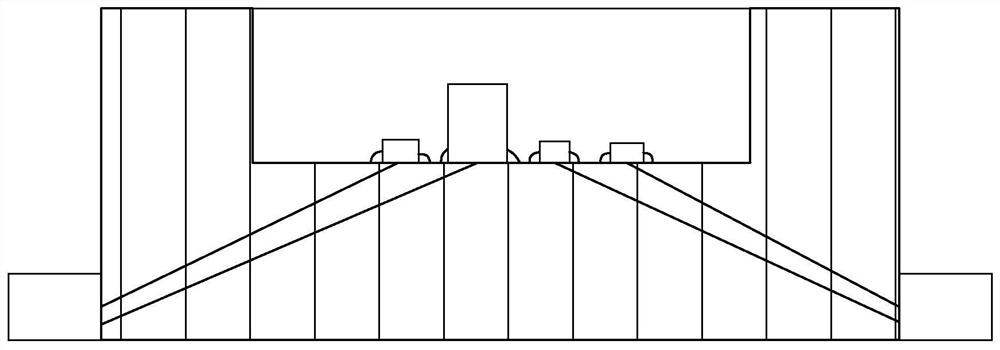

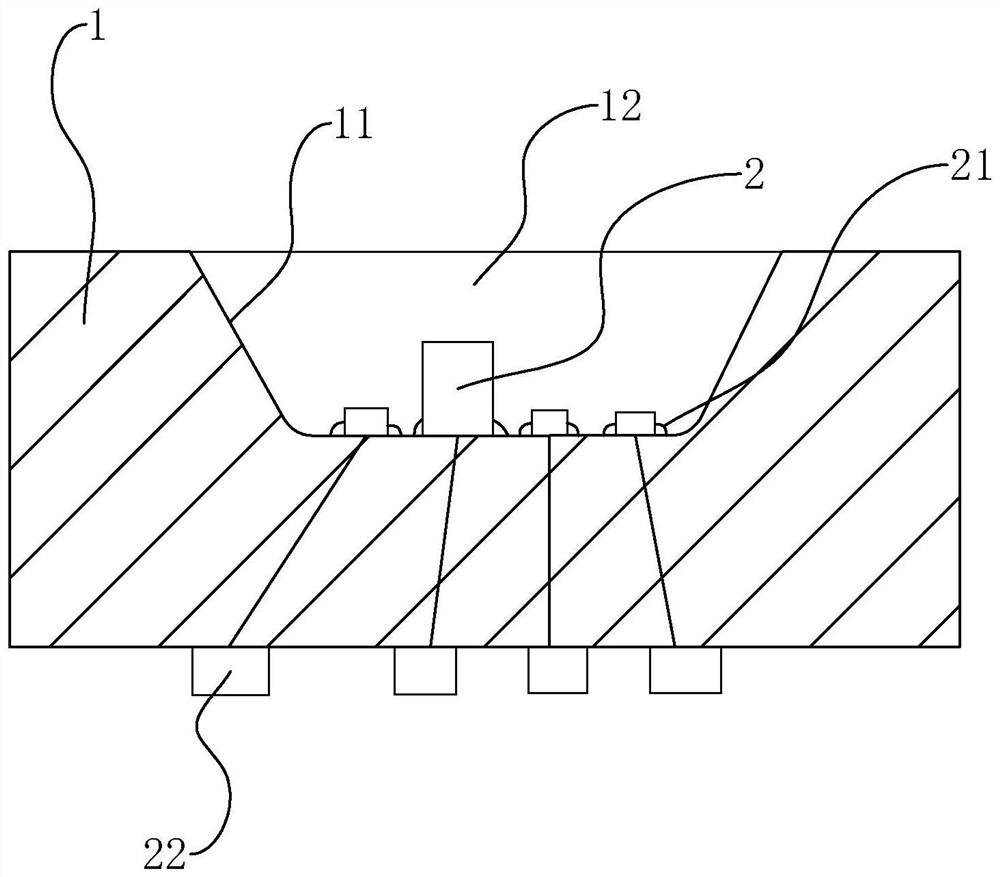

[0037] refer to figure 2 , The LED lamp bead includes a lamp bead base 1, and the lamp bead base 1 is made of glass fiber, mainly epoxy resin. The lamp bead base is in the shape of a cuboid.

[0038] refer to figure 2 , the top surface of the lamp bead base 1 is provided with an installation groove 11, the installation groove 11 is set as a conical shape with a narrow bottom and a wide top, the bottom end surface of the installation groove 11 is set as a plane parallel to the bottom surface of the lamp bead base 1, the top of the installation groove 11 The opening is flush with the top surface of the lamp bead base 1. The expansion of the notch at the top of the installation groove 11 facilitates the installation of the LED chip 2 at the bottom of the installation groove 11 .

[0039] refer to figure 2 , four groups of LED chips 2 are arranged in the installation groove 11, and the four groups of LED chips 2 are all LED lamp beads. Among them, the four groups of LED ch...

Embodiment 2

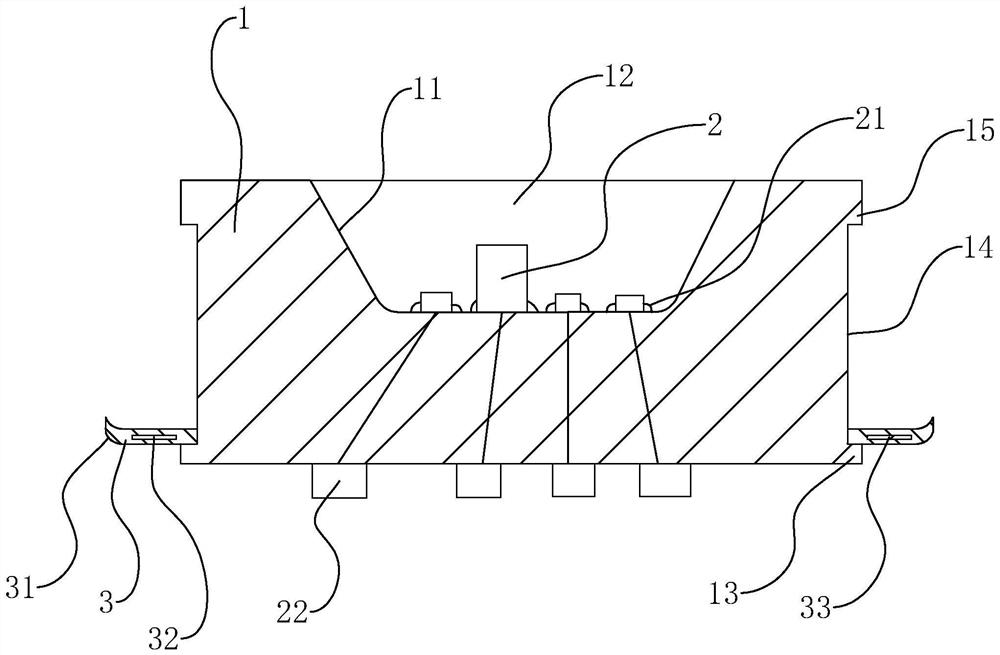

[0048] refer to image 3 The difference between embodiment 2 and embodiment 1 is that the lamp bead base 1 is provided with a sealing piece 3, the outer wall of the lamp bead base 1 is provided with a chute 14, and the length of the chute 14 is set to the outer circumference of the outer wall of the lamp bead base 1 Extending one circle, the width of the slide groove 14 is set to extend along the height of the lamp bead base 1 .

[0049] refer to image 3, the closure piece 3 is in the shape of a "mouth", and the closure piece 3 includes two pieces of the same shape. connected to form the closure piece 3. The inner wall of the sealing piece 3 fits closely with the groove bottom of the chute 14, the sealing piece 3 is arranged horizontally and its outer wall extends out of the chute 14, so that the outer peripheral surface of the sealing piece 3 exceeds the height of the lamp bead base 1 in the vertical direction. peripheral surface. When the bottom surface of the lamp bead...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com