Concrete solid pile vibration platform and production method

A vibrating platform and concrete technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of the thickness of the laitance layer, the resonance of the vibrating table, and the uneven degree of vibration compaction, and achieve the effect of compact structure and prevention of resonance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

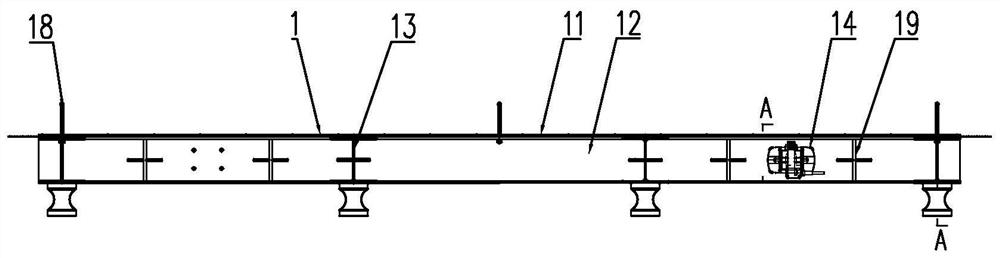

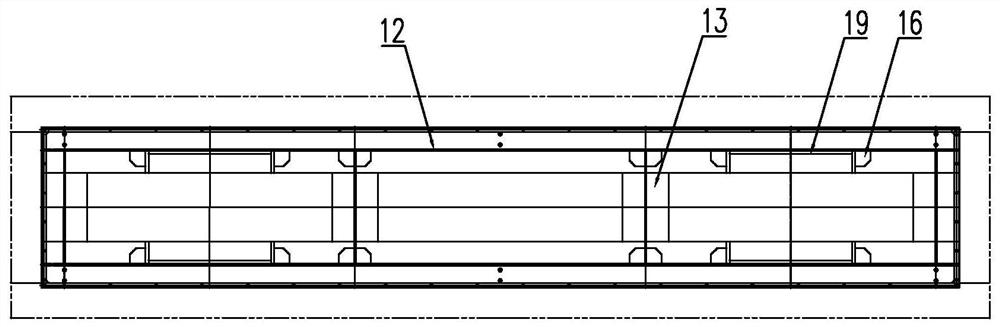

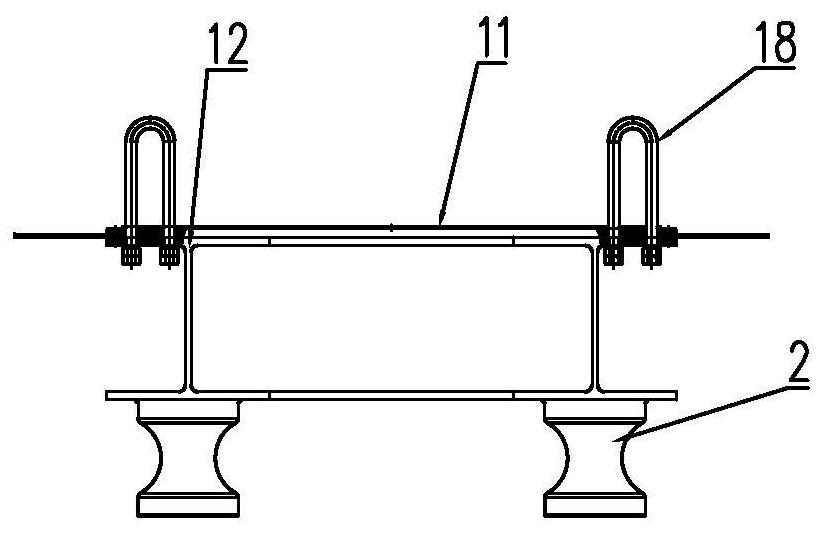

[0022] like Figure 1 to Figure 8 As shown, a concrete solid pile vibration platform includes a platform main body 1 and a support structure 2 for supporting the platform main body 1. The platform main body 1 includes a panel 11 and a main beam 12 and a crossbeam 13 fixed below the panel 11. The main beams 12 are arranged on both sides below the panel 11 , the crossbeams 13 are arranged between the main beams 12 on both sides, and the vibrators 14 are arranged on symmetrical positions of the main beams 12 on both sides. The vibrator 14 is arranged on the main beam 12, and then transmitted to the panel 11, so that the vibration is more uniform and the concrete vibration effect is good. The vibrator 14 is a vibration motor.

[0023] Both the main girder 12 and the cross beam 13 are of H steel structure. The H steel includes two parallel plates and an intermediate plate connecting the two parallel plates. The H steel structure can be finished H-shaped steel, or welded by steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com