One-time reinforcing bar-arranging and rapid forming method of magnesite composite agricultural shed support

A technology of composite materials and agricultural greenhouses, applied in the direction of ceramic molding machines, manufacturing tools, etc., can solve the problems of being unsuitable for large-scale production, low work efficiency, and difficult to form dense slurry, etc., to achieve no honeycomb, dense structure, and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

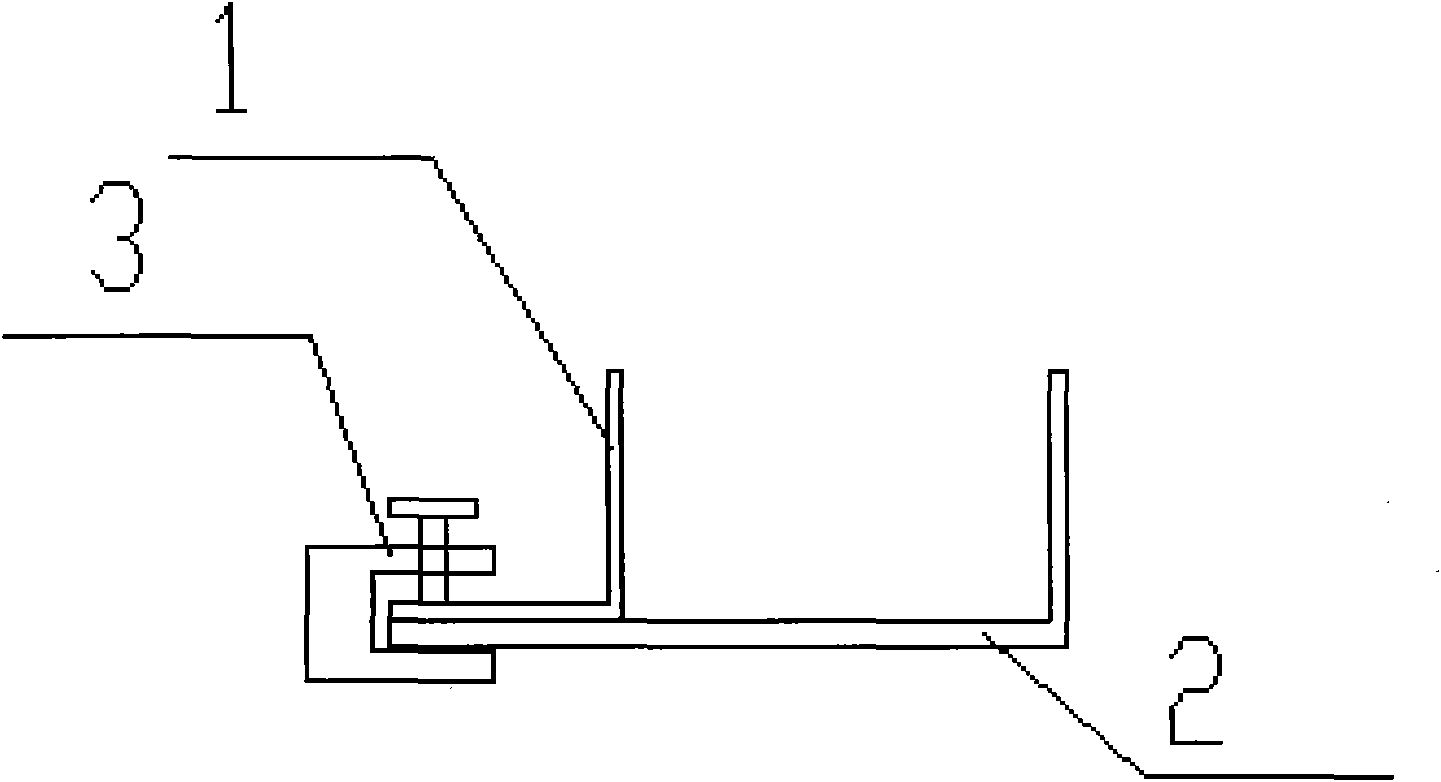

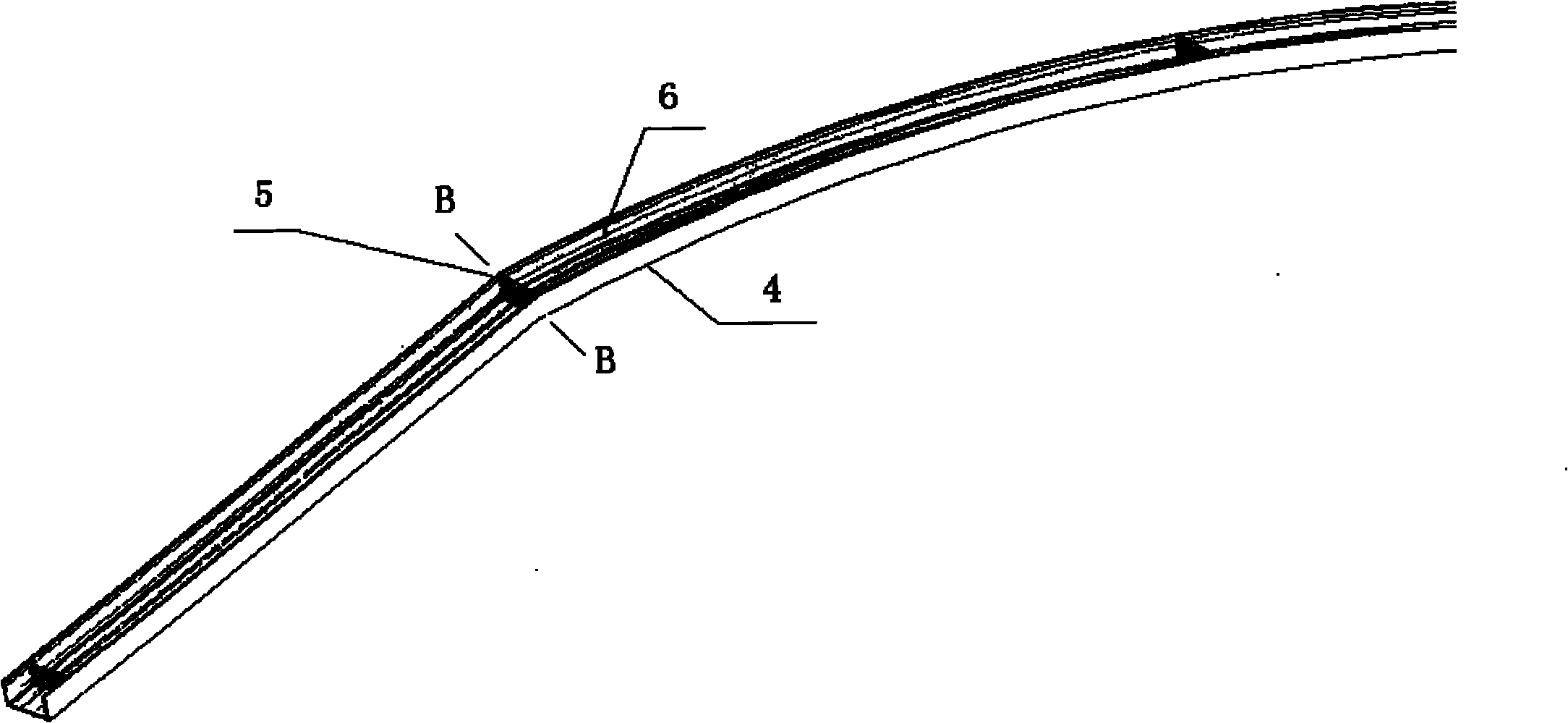

[0018] The forming mold can be made of fiberglass, and its shape is a quarter circle. The inner edge formwork (1) and the outer edge formwork (2) respectively have an end plate, and the inner edge formwork (1) and the outer edge formwork (2) are aligned and positioned through the end plates, and fixed by four fastening clips (3). The 6 bamboo tendons (6) are interspersed and assembled by the stainless steel wire mesh (5) and installed in the mold (4) at one time, so that the bamboo tendons are evenly distributed at equal distances in the mould.

[0019] The composite slurry of magnesite composite material is poured into the greenhouse bracket mold equipped with 6 bamboo bars at one time, and the greenhouse bracket is placed on a 1000mm×4000mm vibrating table. % of the curing room with mold curing 8h demoulding, continue curing at room temperature to 7d after demoulding can be put into use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com